Industries

At home in many sectors

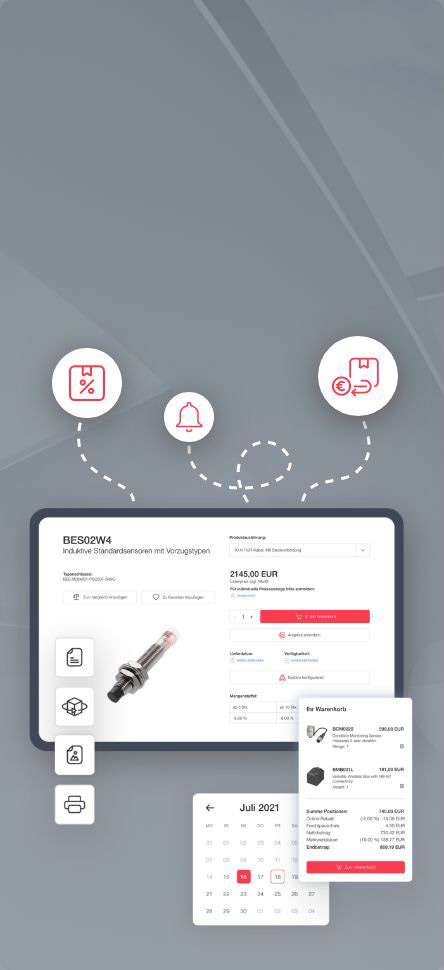

Balluff sensor solutions and systems represent individual products that are optimally adapted to your industry, your application conditions and requirements. Our comprehensive sensor and networking expertise provides technological variety for use all around the globe.

Products

Products