18.06.2021

Balluff Condition Monitoring Toolkit Visualizes Data for Manufacturers

Standalone system provides cost-effective, reliable solution to gain machine condition data

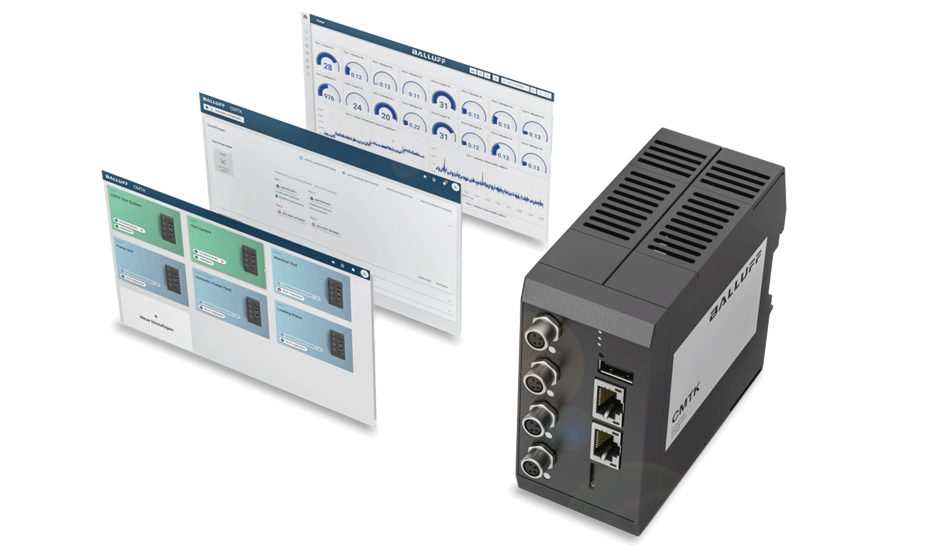

Ballluff’s new condition monitoring toolkit (CMTK) provides an easy-to-implement solution for adding condition monitoring to existing machines and processes with an excellent cost-benefit ratio. With the flexible condition monitoring toolkit, manufacturers can quickly gain deeper insights into the actual condition of their machines and systems, allowing them to detect problems early.

This flexible system for comprehensive machine monitoring provides a smart and low-cost option for retrofitting plants. The condition data gained through the CMTK provides continuous status information on connected machines, allowing for predictive maintenance. This greatly reduces unplanned downtime and the unnecessary costs associated with it. And it does all of this completely independent of a cloud connection or machine control system.

Each system needs only three pieces in order to capture, process and visualize the machine process:

Sensors – up to four IO-Link sensors to obtain condition data from the machines

Software – A one-time purchase, preinstalled on the base unit, it collects the ata to be visualized and evaluated

Base Unit – a small computer that connects to and processes the data from the various sensors

The condition monitoring toolkit works independently, providing actionable data no matter what controls systems are in place. The base unit is a miniaturized computer which can be installed on a DIN rail in a control cabinet for easy deployment. Four IO-Link ports allow to the addition of sensors to measure the factors, like temperature, vibration, humidity and pressure.

Built-in software stores this data, visualizes it on a dashboard, and can send alerts and export data. Built-in LAN ports connect the CMTK either directly to a computer or to an existing computer network. Depending on the sensors selected, the condition monitoring toolkit can be used for various monitoring tasks.

Key features

Unified retrofit solution for machine and process monitoring

High flexibility through the connection of up to four arbitrary IO-Link sensors

Plug-and-play commissioning of the system and visualization of the data

Output of warning messages when adjustable limit values are exceeded

Self-sufficient system with data storage – independent of cloud and machine control

Remote monitoring from any location thanks to network integration

- [email protected]

- 1-800-543-8390

-

8125 Holton Drive

Florence, KY 41042

Products

Products