27.05.2024

Condition Monitoring Sensor BCM Generation 2

Smart condition monitoring at a new level

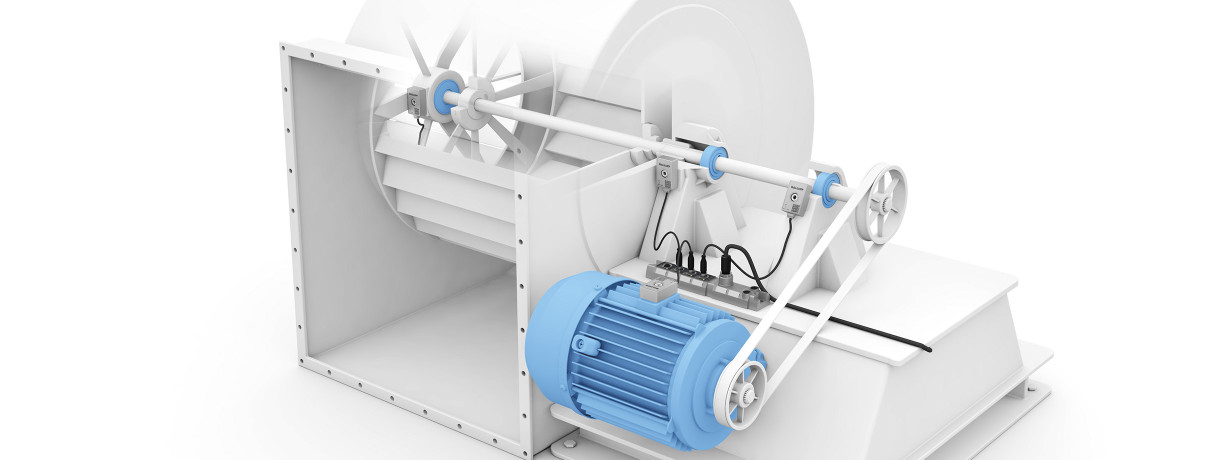

Unplanned downtimes and disruptions in the production process can be efficiently avoided with BCM condition monitoring sensors from Balluff: The intelligent sensors provide condition data that you can use to automate cost-intensive manual inspections. At the same time, this additional data is an important building block for highly automated and networked production.

A standardized IO-Link interface combined with integrated intelligent data pre-processing: the new generation of the popular BCM now sets another milestone in the field of smart IO-Link sensor technology.

From condition monitoring of critical components and assemblies to the detection of critical process states to the detection of relevant process parameters for inline process optimization: With the BCM Generation 2 you solve your condition monitoring applications optimally.

Upgrade instead of Update

The new condition monitoring sensor is not an iterative further development of the first generation, but a completely new platform with different hardware and firmware. The significantly improved measurement performance in combination with more sophisticated algorithms allow the sensor to detect the smallest changes in condition even earlier and more specifically than before.

Features | BCM Generation 2 | BCM Generation 1 |

Measurement performance | 2…4.500 Hz (±10 %) 2…6.000 Hz (3 dB)

| 2…1.800 Hz (±10 %) 2…2.500 Hz (3 dB) |

Operating temperature | -40…80 °C

| -25…70 °C

|

Communication interface | IO-Link + SIO

| IO-Link

|

Data transmission | Up to 24 process values simultaneously | 4 process values simultaneously |

Data preprocessing: | RMS, Peak, Max, Crest Factor, Skewness, Kurtosis | RMS, Peak, Max, Crest Factor, Skewness, Kurtosis |

Data preprocessing: Vibration frequency domain evaluation | NEW: Amplitude spectrum (FFT), Envelope spectrum | - |

Quick and easy installation – even in existing systems

Thanks to the new, convenient mounting concept with just one screw, it is also even easier to install. The small, round mounting surface makes it much easier to prepare for mounting on curved surfaces. This gives you enormous advantages, especially for retrofit solutions.

One M5 mounting screw 50 % less effort to drill holes

⌀ 22 mm mounting surface: 40 % space reduction

Less failure potential during installation

Higher measurement performance

Easier alignment of the axes

Alignment can be easily adjusted

In short: Compared to the first generation, the new BCM scores with an even significantly higher performance level, intelligent algorithms and a sophisticated and efficient mounting concept.

Application data: intelligent – integrated

The integrated data pre-processing enables lean, cost-effective condition monitoring systems to be set up and applications to be solved for which additional high-end evaluation units were previously required. Frequency spectra for all three measurement axes are calculated in real time from the very high-frequency measurement data and made available for specific applications - the ideal basis for monitoring your processes without having to transmit huge amounts of data through various network systems. In short, data volumes can be reduced to the essentials and unnecessary data traffic is avoided.

At the same time, the process data concept is so flexible that you can implement several monitoring functions - e.g. ISO vibration monitoring, bearing monitoring, imbalance detection or temperature monitoring - with just one sensor.

The variants of the BCM Generation 2 available from Balluff differ primarily in the degree of integrated data preprocessing, so you are guaranteed to find the right sensor for your application.

1. Bearing damage, 2. Imbalance, 3. Blades damage

1. Bearing damage, 2. Imbalance, 3. Blades damage

Earliest possible detection

of potential machine downtimes

Intelligent algorithms

enable frequency-selective analysis of critical components

Significant increase in measurement performance

in the detection of high-frequency phenomena

Innovative housing concept

for convenient, fast and reliable mounting

Features

- Smart condition monitoring sensor with standardized IO-Link interface

- Several measured variables in one device: vibration and temperature

- Very high performance of vibration measurement with a frequency range of up to 6 kHz in three measurement axes

- Early and targeted detection of critical condition changes through integrated frequency analysis

- Simple and efficient installation and retrofitting due to sophisticated mounting concept

- Sensor self-monitoring with Balluff Smart Automation and Monitoring System (SAMS)

The new generation of BCM condition monitoring sensors

Basis Analytics / Vibration & Temperature

- Function

-

Vibration analysis in time domain

Contact temperature monitoring - Vibration, frequency range

-

2...4500 Hz (±10 %)

2...6000 Hz (±3 dB) - Vibration, number of measuring axes

- 3

- Vibration, measuring range

- -16…16 g

- Contact temperature, measuring range

- -40…+80 °C

- Rated operating voltage Ue DC

- 24 V

- Interface

- IO-Link 1.1.3

- Connection

- Cable with connector, M12x1-Male, 4-pin, 1.5 m, PUR

- Housing material

- Stainless steel 1.4404 (316L)

- IP rating

- IP67, IP68, IP69K

- Ambient temperature

- -40...80 °C

- Secondary features

-

Identification

Device Discovery

Switching Counter

Operating Hours Counter

Boot Cycle Counter

Voltage and Current Monitoring

Pin Assignment - Secondary features for condition monitoring

- Internal temperature monitoring

- Function

-

Vibration analysis in time domain

Vibration analysis in frequency range

Rotational speed input

Contact temperature monitoring - Vibration, frequency range

-

2...4500 Hz (±10 %)

2...6000 Hz (±3 dB) - Vibration, number of measuring axes

- 3

- Vibration, measuring range

- -16…16 g

- Contact temperature, measuring range

- -40…+80 °C

- Rated operating voltage Ue DC

- 24 V

- Interface

- IO-Link 1.1.3

- Connection

- Cable with connector, M12x1-Male, 4-pin, 1.5 m, PUR

- Housing material

- Stainless steel 1.4404 (316L)

- IP rating

- IP67, IP68, IP69K

- Ambient temperature

- -40...80 °C

- Secondary features

-

Identification

Device Discovery

Switching Counter

Logic Blocks

Operating Hours Counter

Boot Cycle Counter

Voltage and Current Monitoring

Pin Assignment - Secondary features for condition monitoring

- Internal temperature monitoring

Sensors working together – Smart RPM input

The current RPM plays a decisive role in monitoring the condition of rotating components (e.g. rolling bearings, gear wheels). This information is particularly important for frequency-based pre-processing (FFT). The RPM can be continuously provided to the BCM via the machine control system. The problem is often - especially when retrofitting existing systems - that this option is not available. We therefore offer another alternative with the smart RPM input.

EXTERNAL RPM INPUT

Stream pulse signal from any binary sensor with PNP or push-pull switching output directly into the Condition Monitor Sensor

ONBOARD PROCESSING

Conversion to rotational speed (RPM) by Condition Monitor Sensor | Rotational speed-dependent onboard analysis on the Condition Monitor Sensor

IO-LINK COMMUNICATION

Transmission of vibration parameters (e.g., bearing frequencies) and RPM via IO-Link

Networking modules

- Processor

- 1.8 GHz / 400MHz

- Working memory

- 2 GB RAM

- Connection slots

-

2x LAN: RJ45-Female, 8-pin

4x IO-Link: M8x1-Female, 4-pin, A-coded

PWR: Phoenix MC1.5/3-STF-3.81

USB: USB 2.0 Standard-A - Dimension

- 101 x 126 x 50 mm

- Data storage

- 8 GB EMMC

- Interface

- PROFINET / EtherNet/IP

- Interface IIoT

- REST API, MQTT

- Auxiliary interfaces

- 8x IO-Link

- Port-class

- Type A

- Output current max.

- 0.25 A

- Display

- no

- Operating voltage Ub

- 18...30 VDC

- Connection (COM 1)

- M12x1-Female, 4-pin, D-coded

- Connection (COM 2)

- M12x1-Female, 4-pin, D-coded

- Connection (supply voltage IN)

- M12x1-Male, 2-pin, A-coded

- Connection slots

- 8x M12x1-Female, 5-pin, A-coded

- Digital inputs

- 16x PNP, Type 3

- Digital outputs

- 8x PNP

- Configurable inputs/outputs

- yes

- Current sum US, sensor

- 4.0 A

- Housing material

- PC, injection molding

- Dimension

- 59 x 36.8 x 180 mm

- Ambient temperature

- -25...55 °C

- IP rating

- IP67

- IO-Link version

- 1.1.3

- Safety Hub Support

- no

- Scope of delivery

- Grounding strap

- Not incl. in scope of delivery

-

Label plates

Port cover

Y connectors for RPM

- Connection 1

- M12x1-Male, straight, 3-pin, A-coded

- Connection 2

- M12x1-Female, straight, 5-pin, A-coded

- Connection 3

- M12x1-Female, straight, 5-pin, A-coded

- Operating voltage Ub

- 250 VDC / 250 VAC

- Cable

- PUR black, drag chain compatible

- Rated current (40 °C)

- 4.0 A

- Cable temperature, fixed routing

- -50...90 °C

- Cable temperature, flexible routing

- -25...90 °C

- IP rating

- IP67, IP68, IP69K/IP67, IP68, IP69K

- Approval/Conformity

-

CE

WEEE

cULus

- Connection 1

- M12x1-Male, straight, 3-pin, A-coded

- Connection 2

- M12x1-Female, straight, 5-pin, A-coded

- Connection 3

- M12x1-Female, straight, 5-pin, A-coded

- Operating voltage Ub

- 250 VDC / 250 VAC

- Cable

- PUR black, drag chain compatible

- Rated current (40 °C)

- 4.0 A

- Cable temperature, fixed routing

- -50...90 °C

- Cable temperature, flexible routing

- -25...90 °C

- IP rating

- IP67, IP68, IP69K/IP67, IP68, IP69K

- Approval/Conformity

-

CE

WEEE

cULus

- Connection 1

- M12x1-Male, straight, 3-pin, A-coded

- Connection 2

- M12x1-Female, straight, 5-pin, A-coded

- Connection 3

- M12x1-Female, straight, 5-pin, A-coded

- Operating voltage Ub

- 250 VDC / 250 VAC

- Cable

- PUR black, drag chain compatible

- Rated current (40 °C)

- 4.0 A

- Cable temperature, fixed routing

- -50...90 °C

- Cable temperature, flexible routing

- -25...90 °C

- IP rating

- IP67, IP68, IP69K/IP67, IP68, IP69K

- Approval/Conformity

-

CE

WEEE

cULus

- Connection 1

- M12x1-Male, straight, 3-pin, A-coded

- Connection 2

- M12x1-Female, straight, 5-pin, A-coded

- Connection 3

- M12x1-Female, straight, 5-pin, A-coded

- Operating voltage Ub

- 250 VDC / 250 VAC

- Cable

- PUR black, drag chain compatible

- Rated current (40 °C)

- 4.0 A

- Cable temperature, fixed routing

- -50...90 °C

- Cable temperature, flexible routing

- -25...90 °C

- IP rating

- IP67, IP68, IP69K/IP67, IP68, IP69K

- Approval/Conformity

-

CE

WEEE

cULus

Sensors for RPM input

- Series

- 6K

- Dimension

- 12 x 34 x 21.6 mm

- Interface

-

IO-Link-Device: 1.1.3

PNP/NPN/IO-Link: NO/NC - Input function

-

Key disable on/off

Same function as button - Principle of operation

- Photoelectric sensor

- Principle of optical operation

- Diffuse sensor, energetic

- Beam characteristic

- Focused

- Light type

- Laser red light

- Light spot size

- 0.7 x 0.7 mm at 250 mm

- Range

- 1...250 mm

- Connection

- Connector, M8x1-Male, 4-pin

- Housing material

- ABS

- Material sensing surface

- PMMA

- Operating voltage Ub

- 10...30 VDC

- Approval/Conformity

-

CE

UKCA

cULus

WEEE

- Series

- 6K

- Dimension

- 12 x 34 x 21.6 mm

- Interface

-

IO-Link-Device: 1.1.3

PNP/NPN/IO-Link: NO/NC - Input function

-

Key disable on/off

Same function as button - Principle of operation

- Photoelectric sensor

- Principle of optical operation

- Diffuse sensor, triangulation

- Special optical feature

- Background suppression

- Beam characteristic

- Divergent

- Light type

- LED Blue light

- Light spot size

- 10 x 10 mm at 150 mm

- Range

- 1...200 mm

- Connection

- Connector, M8x1-Male, 4-pin

- Housing material

- ABS

- Material sensing surface

- PMMA

- Operating voltage Ub

- 10...30 VDC

- Approval/Conformity

-

CE

UKCA

cULus

WEEE

- Dimension

- Ø 12 x 50 mm

- Style Housing

- M12x1

- Installation

- non-flush

- Range

- 8 mm

- Switching output

- PNP normally open (NO)

- Switching frequency

- 2000 Hz

- Housing material

- Brass, PTFE coated

- Material sensing surface

- PBT

- Connection

- Connector, M12x1-Male, 3-pin

- Operating voltage Ub

- 10...30 VDC

- Ambient temperature

- -40...85 °C

- Magnetic field immune

- magnetic field immune (AC/DC)

- IP rating

- IP68

- Approval/Conformity

-

CE

UKCA

WEEE

cULus - Additional features

-

Factor 1

Extended temperature range

Housing resistant to weld spatter

weld-immune (magnetic field 100kA/m)