11.05.2023

Long Distance Positioning System (LDPS)

Reliable, intelligent and adaptable position measurement up to 1.5 km

Long distances are no longer an obstacle for the intelligent BTL LDPS magnetostrictive position measuring system. Where highest precision in position and speed measurement is required, Balluff offers an absolute distance measuring system that can continuously determine positions up to a distance of 1.5 km with a repeat accuracy of 0.5 mm. This makes the system ideally suited for applications on overhead traveling cranes, loading bridges, gantry cranes, reversing controls, and crane and trolley travel, turning process cranes into large-scale robots.

Intelligent sensor technology travels with the crane

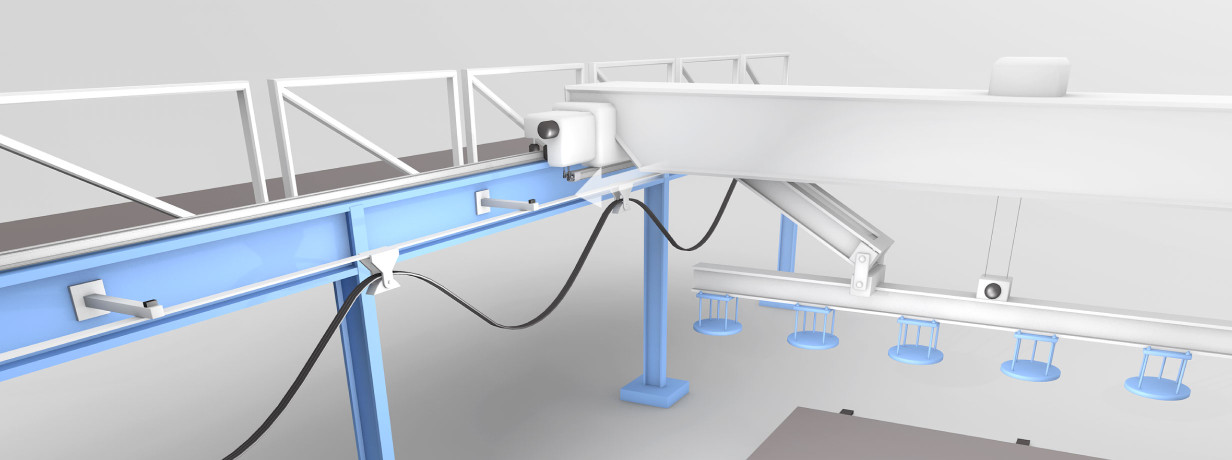

The Long Distance Positioning System (LDPS) consists of a magnetostrictive position measuring system, with a Profinet interface, and several position sensors installed along the travel path of a crane, whose position is read by the magnetostrictive sensor mounted on the crane. This information is transmitted to the controller, which calculates the absolute coordinates of the crane position with high accuracy. In addition, you receive a software function block for easy integration into your control system.

The measuring system is also available with a fail-safe operating option with redundant markings along the travel path, which further increases the efficiency, reliability and quality of your application. The system operates without wear or maintenance and is insensitive to shock, vibration and contamination.

Crane systems are used worldwide and across industries for transporting goods in intralogistics, warehouse management or in various production processes. The loads here are often very high and the environment also places enormous demands on the sensor technology. In addition, the operator must always be aware of the absolute position of the crane or the control system.

Crane systems are used worldwide and across industries for transporting goods in intralogistics, warehouse management or in various production processes. The loads here are often very high and the environment also places enormous demands on the sensor technology. In addition, the operator must always be aware of the absolute position of the crane or the control system.

This applies all the more if there are two or more cranes on one runway. For correct positioning and to avoid collisions of cranes, laser sensors are usually used, which meet common performance requirements under normal environmental conditions. However, if the level of contamination in a hall is high or if the cranes are operated outdoors, laser-based systems reach their limits.

Bang Kransysteme has put Balluff's Long Distance Positioning System through its paces: "The distance measuring system, which travels along with the crane and is approximately four meters long, detects the position sensors that are mounted along the travel path according to a predefined scheme and uses this information to calculate the absolute crane position. If knowledge of this position is essential, even under adverse conditions, the system is ideally suited!" summarizes David Böttiger, Automation Manager.

Features and advantages at a glance

- Absolute linear position measuring system with a measuring range of up to 1.5 kilometers

- High reliability and low maintenance due to a non-contact and wear-free operating principle

- Resistance in harsh industrial environments (IP67)

- Flexible installation and automatic adaptation of the system to the magnetic markings

- Repeatability up to ±0.5 mm

Downloads

-

Magnetostrictive linear position sensor with a measuring range of up to 1.5 kilometers