Vibration monitoring

Especially in the field of rotating machines, equipment, and individual components, vibration monitoring is a suitable form of condition monitoring. Excessive vibrations can lead to sudden problems in operation and massively restrict production.

To counteract this, we have developed a Condition Monitoring Toolkit to keep an eye on the vibration conditions of your machines. At any point in time, the development of vibrations is displayed for you. You can define limit values for the vibrations in advance, and if these values are exceeded, a warning is issued to prevent, for example, bearing damage, loose mounts or shocks caused by impacts and the resulting possible production downtime.

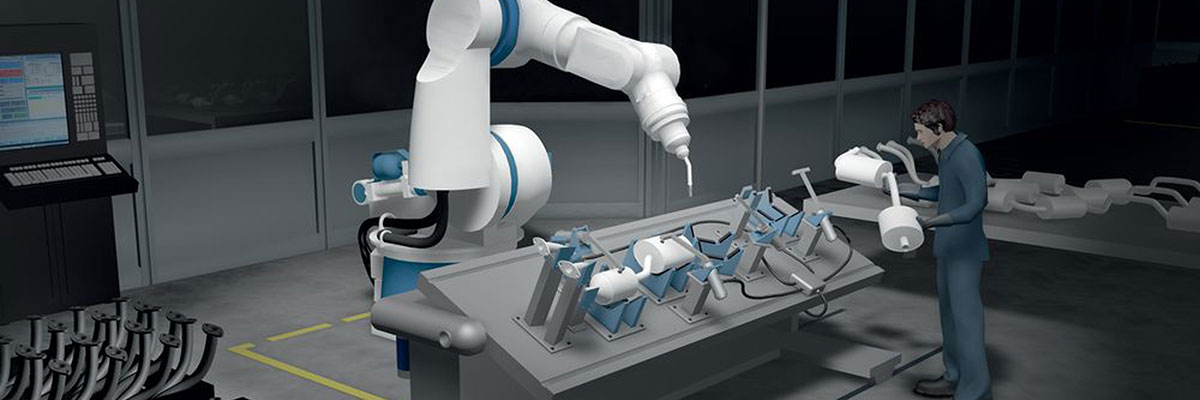

Monitoring multi-axis industrial robots

The CMTK reliably detects shocks, vibrations and other events or irregularities in the operation of industrial robots. Particularly due to their multi-axis design, they are extremely susceptible to vibrations, which can result in serious damage. Signs of wear and tear as a result of shocks with overloading of individual components can easily lead to unplanned shutdowns, if they go unnoticed. In order to avoid production and machine downtimes, Balluff's CMTK records and visualizes the vibration data from your industrial robot and enables you to derive an optimal maintenance strategy.

The CMTK reliably detects shocks, vibrations and other events or irregularities in the operation of industrial robots. Particularly due to their multi-axis design, they are extremely susceptible to vibrations, which can result in serious damage. Signs of wear and tear as a result of shocks with overloading of individual components can easily lead to unplanned shutdowns, if they go unnoticed. In order to avoid production and machine downtimes, Balluff's CMTK records and visualizes the vibration data from your industrial robot and enables you to derive an optimal maintenance strategy.

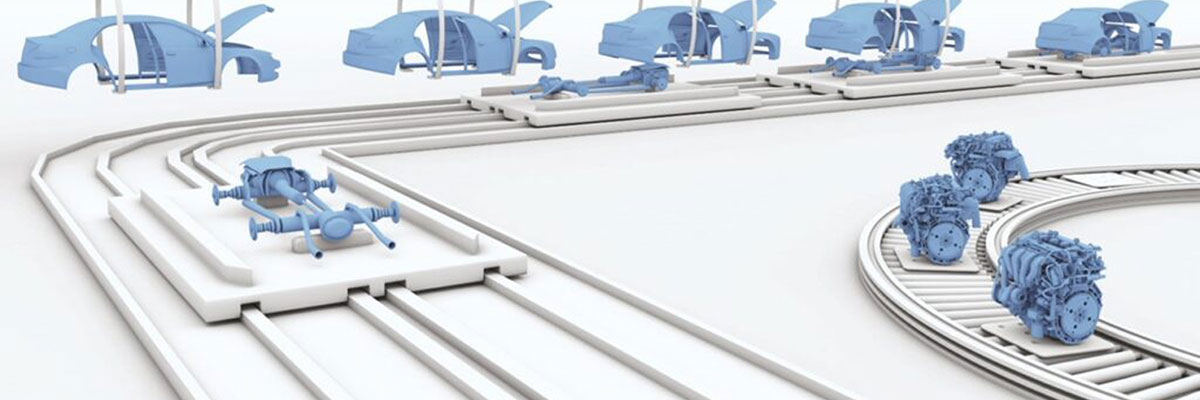

Vibration monitoring of conveyor belts and transport systems in production

In production, it is not uncommon for machines to be in operation for more than just one work unit. Conveyor belts and associated transport systems are particularly stressed. Our sensors not only help you to detect unusual vibrations and oscillations, but also to detect deviations in conveyor performance.

In production, it is not uncommon for machines to be in operation for more than just one work unit. Conveyor belts and associated transport systems are particularly stressed. Our sensors not only help you to detect unusual vibrations and oscillations, but also to detect deviations in conveyor performance.

In this way, the CMTK system helps you to plan maintenance measures at an early stage so that failures are avoided as much as possible.