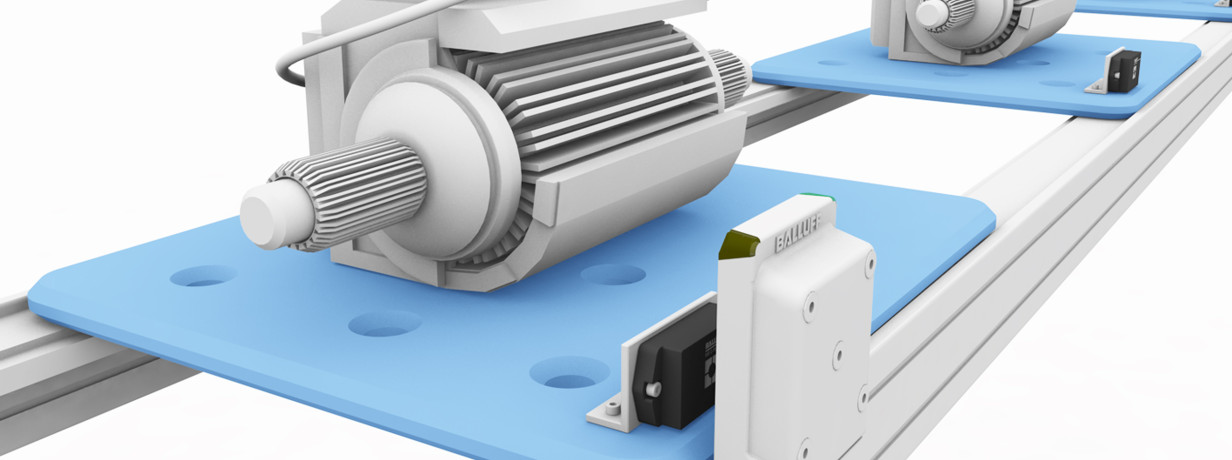

Transparency and flexibility in electric motor assembly

By identifying with RFID you always have the overview of your electric motor assembly because the non- contact technology documents every production step quickly and reliably. Ethernet communication makes the system especially flexible. And with our All-in-One RFID reader it's an extremely economical solution. You eliminate the processor unit, since the rugged read/write head is connected directly to the controller level through the Profinet or Ethernet/IP interface.

The features

- Robust die-cast zinc housing for installation directly on metal

- Diagnostics directly on the equipment using 360 deg. visible LEDs

- Integrated web server for convenient remote condition monitoring

- Simple system expansion with integrated 2-port Ethernet switch

Related topics

Downloads

-

Industry brochure automotive