- Matrix Vision solutions now all under the Balluff brand

- Condition Monitoring

- Smart Automation and Monitoring System

- Comprehensive components and solutions for automated welding

- IO-Link: Intelligent solutions for modern automation

- Architects of Smart Manufacturing

- Explosion Protection

- Level Detection

- MicroSPOT

- Miniaturization

- Tough Performers

- Quality Assurance

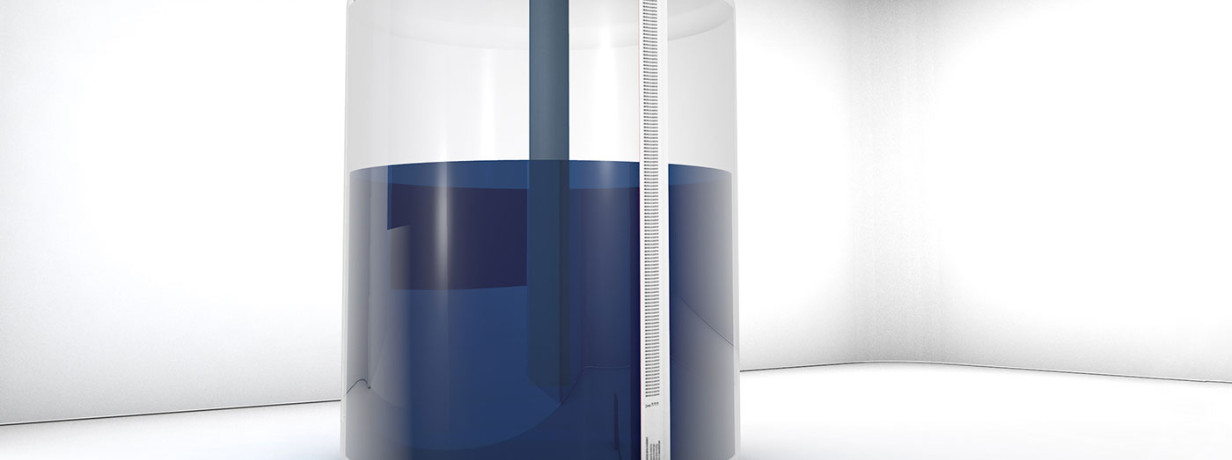

- Using magnetostrictive linear position sensors to monitor levels on non-magnetic containers

- Capacitive sensor head detects over a large range

- Ultrasonic sensors – chemically resistant, non-contacting and precise even under pressure

- BTL level sensor for maintaining the highest hygienic standards

- Using hydrostatic pressure sensors for detecting the level in storage tanks

Capacitive sensor head detects over a large range

Our self-adhesive capacitive sensor head is especially suited for non-contacting, continuous level detection on container or pipe outer walls with a generous detection range. The sensor head is flexible and can be trimmed to the desired length. Thanks to its integrated adhesive surface you can attach it easily to container walls without any additional accessories. The separately available amplifiers make it possible to continuously detect fill levels with analog output or via IO-Link. This means you can use a sensor to immediately detect a minimum or maximum value violation. At the same time you can use the sensor to measure the level over the entire range.

Features

- Continuous measurement

- Non-contacting

- Can be trimmed to size (min. 108 mm)

- Detection range up to 850 mm

- Flexible sensor surface

- Versatile setting options using analog or IO-Link