IO-Link Wireless

Sensor communication at a new level

We speak IO-Link – both wired and wireless. Balluff's extensive IO-Link portfolio includes numerous sensors and actuators as well as an unrivaled range of networking and connectivity technology. IO-Link Wireless is a modern and future-proof extension of our product range. The new wireless IO-Link variant is the ideal complement for the next generation of machines and systems, and it is perfectly suited to further optimize existing systems.

Wireless communication in industrial automation

IO-Link Wireless does not serve as a replacement for wired solutions, but is instead an extension that makes it possible to benefit from all of the advantages of wired IO-Link solutions wirelessly.

Currently, it takes a lot of cabling for communication, both at the machine level and for manufacturing as a whole. In some applications, especially for a variety of motion control solutions, wired communication is not a good option.

With IO-Link Wireless, you gain the full flexibility needed by many automation solutions. It enables control and monitoring across your enterprise in real time and with a cable-quality connection, without the use of wires.

IO-Link Wireless is extremely reliable--many times more so than traditional W-LAN or Bluetooth wireless networks. It is also very robust and resistant to interference when it is in the vicinity of other systems or other sources of wireless and electromagnetic interference. Even extreme industrial conditions do not keep IO-Link Wireless from functioning smoothly.

With very high scalability and adaptability, the technology is very well suited for any system or machine. Up to 40 devices can be connected to an IO-Link Wireless Master using five tracks.

Balluff products can be installed and integrated into your existing machines and systems. This enables wireless modernization with the latest sensor technology even in existing machines and systems.

IO-Link Wireless makes it possible to use IO-Link in machine areas where it was previously not possible. The connected and intelligent factory of the future is accelerating, and wired technologies no longer have to be the absolute standard.

The advantages of IO-Link Wireless for automation at a glance

The IO-Link Wireless communication standard brings many advantages over a wired system, including even more flexible and sustainable integration of sensors/actuators, with the proven reliability and performance of wired IO-Link.

Wireless data transmission with IO-Link Wireless

If you already have IO-Link in use, learn more about the advantages of expanding your system with IO-Link Wireless.Application areas for IO-Link Wireless

IO-Link Wireless facilitates the operation of dynamic, mobile and hard-to-reach applications. Here are a few of the application areas that can benefit from the new IO-Link Wireless technology:

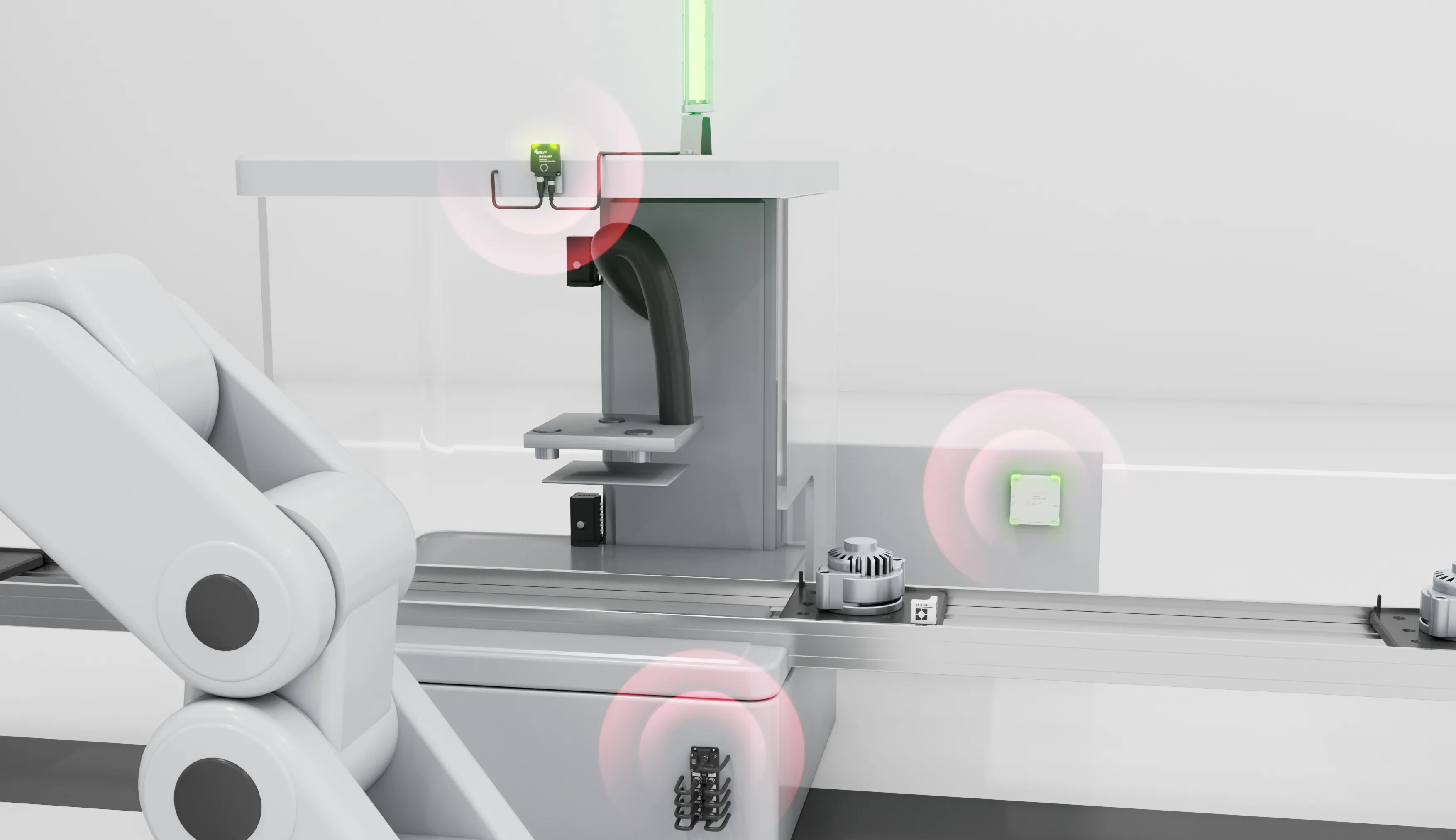

Wireless sensor technology for robotics and transport systems

Dynamic motion sequences in three axes, such as those used in robotics, make cabling complex and costly. Fixed sensor and actuator wiring comes with disadvantages because cables and contacts are subject to high stress, fatigue or breakage due to bending and twisting forces. This can lead to increased and unplanned machine downtime.

For robots, robotic arms and transport systems, non-contact data transmission enables new applications that were not feasible before. In combination with our inductive couplers (BIC) for supplying a non-contact power source, new use cases will be possible.

This solution is based on the international IO-Link wireless standard. Controlling your applications, especially the data transmission and processing, can be done wirelessly. This ensures reliable control of your machines and systems.

Retrofitting your existing systems with the help of IO-Link Wireless

The use of IO-Link Wireless technology makes sense when upgrading existing systems. This is because there is no need to modify the entire architecture of the plant. If you want to begin retrofitting your machines and systems first, our solutions are easy to integrate and do not interfere with the existing architecture.

We offer various solutions for retrofitting and then expanding sensor technology in your existing machines and plants. This makes it possible to flexibly and cost-effectively retrofit your existing machines and systems wherever the complex requirements of running cables had kept it from being possible or economically feasible before.

Wireless automation in harsh environments

Certain industries, such as food processing, require extremely clean environments. It is important to avoid any potential source of contamination whenever possible. IO-Link Wireless supports this by reducing the use of cable, making it ideally suited for the food & beverage sector.

Harsh environmental conditions are also prevalent in the welding sector. This causes cable breaks and failures to occur more often. Cables have to be replaced frequently, which can result in unplanned downtime and production losses. Reducing the number of cables by using IO-Link Wireless solutions can lead to less maintenance and cost savings.

IO-Link Wireless: Individual components

The IO-Link Wireless master is responsible for communication between devices and the programmable logic controller (PLC). The master can communicate with up to 40 devices. A device can currently be an IO-Link sensor/actuator connected to a bridge or a hub with up to 8 connected analog sensors.

The IO-Link Wireless bridge can connect to any standard IO-Link device, enabling wireless transmission of data from that device.

With the IO-Link Wireless hub, up to 8 digital I/Os can be connected to the IO-Link Wireless system.

IO-Link Wireless hub

- Interface

- IO-Link wireless 1.1

- Radio license

-

Europe (CE)

United Kingdom (UKCA)

USA (FCC)

Canada (ISED)

Mexico (CRT/IFT/NOM) - Operating voltage Ub

- 18...30.2 VDC

- Connection (supply voltage IN)

- M12x1-Male, 4-pin, A-coded

- Connection slots

- 8x M12x1-Female, 5-pin, A-coded

- Digital outputs

- 16x PNP

- Configurable inputs/outputs

- yes

- Single-channel monitoring

- yes

- Current sum UA, actuator

- 4 A

- Switching current

- 16x 350 mA

- Current sum US, sensor

- 2 A

- Housing material

- PBT

- Dimension

- 58 x 30.8 x 155 mm

- Ambient temperature

- -5...50 °C

- IP rating

- IP65, when threaded in

- Process data cycle min.

- 5 ms

- Process data IN

- 2 bytes

- Process data OUT

- 2 bytes

IO-Link Wireless bridge

- Interface

- IO-Link wireless 1.1.3;IO-Link

- Radio license

-

USA (FCC)

Canada (ISED)

Europe (CE)

United Kingdom (UKCA) - Operating voltage Ub

- 18...30.2 VDC

- Connection (supply voltage IN)

- M12-Male, 4-pin, A-coded-coded

- Connection slots

- M12-Female, 4-pin, A-coded-coded

- Configurable inputs/outputs

- no

- Current sum UA, actuator

- 2 A

- Current sum US, sensor

- 1 A

- Housing material

- PA 12, Semitransparent

- Dimension

- 53 x 22.5 x 70.9 mm

- Ambient temperature

- -5...50 °C

- IP rating

- IP67/IP67

- Process data cycle min.

- 5 ms

- Process data IN

- 32 bytes

- Process data OUT

- 32 bytes

IO-Link Wireless master

- Fast Start-Up (FSU)

- yes

- Radio license

-

Europe (CE)

United Kingdom (UKCA)

USA (FCC)

Canada (ISED)

Mexico (CRT/IFT/NOM) - Operating voltage Ub

- 18...30.2 VDC

- Connection (COM 1)

- M12x1-Female, 4-pin, D-coded

- Connection (supply voltage IN)

- M12x1-Male, 4-pin, A-coded

- Current sum US, sensor

- 0.2 A

- Housing material

-

PC, coated

ABS, Zinc, Die casting - Dimension

- 130 x 50.5 x 130 mm

- Ambient temperature

- -5...50 °C

- IP rating

- IP54

- Auxiliary interfaces

- Profinet

- IO-Link version

- 1.1

Various wireless solutions from Balluff

At Balluff, in addition to IO-Link Wireless, we offer other solutions that use wireless transmission technologies. To offer optimal solutions for the specific applications of our customers, we developed a kind of toolbox which consists of various wireless solutions.

Our ambition with these different wireless solutions is not to replace cables but to create connections that are more reliable and flexible than cables.