18.12.2020

Inductive Positioning System

Detect positions continuously and without contact

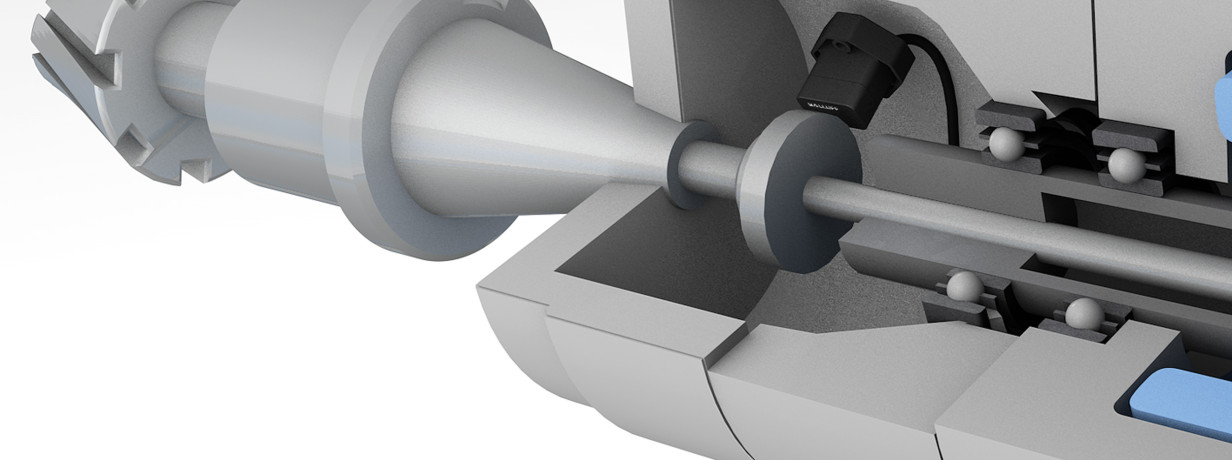

Compact, precise tool spindles and tool changers on a machining center play a central role in the work process. This makes reliable and wear-free monitoring of the clamping process critical. Meet this demanding challenge easily with the new BIP01 inductive positioning system. You also benefit from its high process security and outstanding automation quality.

The positioning system offers you comprehensive diagnostic data, which can be read over an IO-Link interface. In addition to the measurement values, you also receive information about the device's status or current ambient conditions. An integrated stroke counter detects the number of clamping actions and issues warnings when a configured limit value is exceeded. An internal runtime counter continuously monitors the operating hours over the entire life of the sensor, both since the last service and the last start-up. The variety of data provided in real time helps you better achieve an efficient operation.

Features

- Flexible: Measuring range can be set for up to 17 mm

- For a variety of applications: Analog voltage and current output as well as IO-Link interface

- Reliable results: High linearity and precise repeat accuracy

- High process security: Low temperature drift

- Ready for IIoT: Format change, condition monitoring and predictive maintenance

Related topics

Downloads

-

Inductive positioning system: detect positions continuously and without contact

Products

Products