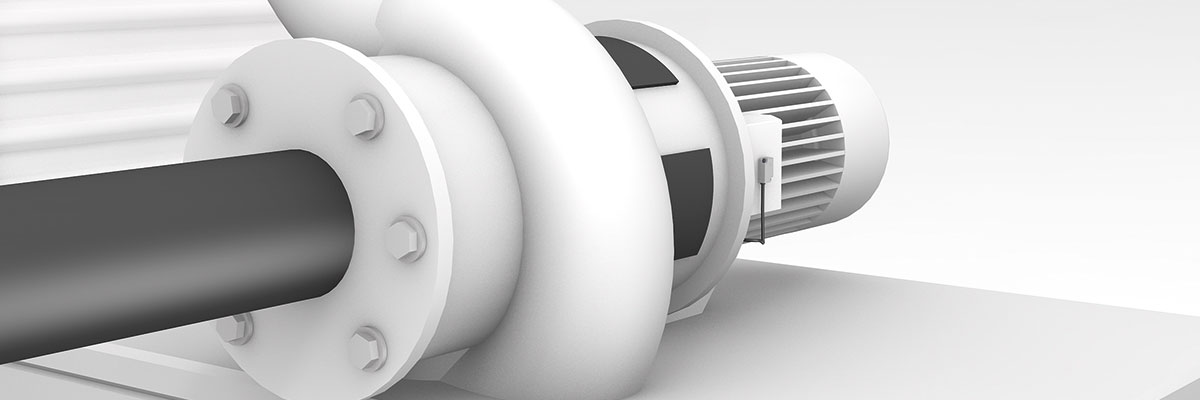

Pump monitoring

You want to efficiently monitor your pumps? Balluff can help you! In order to keep your maintenance costs low and avoid failures due to machine downtime, Balluff developed the Condition Monitoring Toolkit. With it you can stay informed on relevant machine data at all times and from anywhere to detect changes at an early stage and prevent failures.

You want to efficiently monitor your pumps? Balluff can help you! In order to keep your maintenance costs low and avoid failures due to machine downtime, Balluff developed the Condition Monitoring Toolkit. With it you can stay informed on relevant machine data at all times and from anywhere to detect changes at an early stage and prevent failures.

More operational reliability through pump monitoring

With the Condition Monitoring Toolkit from Balluff, machine data from your pump systems can be reliably recorded and evaluated. Based on limit values and control values you define, you are informed about changes at an early stage. These timely warnings enable you to act quickly and plan maintenance work on your pumps to avoid downtime.

This fully automated information processing saves you the effort of manual pump monitoring and thus reduces costs.

Scheduled maintenance of your pumps

With the integrated CMTK solution, you get all the necessary monitoring components from a single source. Regardless of the pumps you currently use, the Condition Monitoring Toolkit can be implemented in your company. Always keep an eye on your pumps and the machines and systems that depend on them to avoid production downtime and unplanned maintenance.

By recording and storing data, you document the pressure conditions and vibrations at pumps and tanks. You can react immediately to deviations in these measured variables, as this information can be sent to any location at any time.

Sensor data acquisition for pump monitoring

Any IO-Link sensor can be used for data acquisition. Whether it's a vibration sensor, temperature sensor or pressure sensor, you can attach up to four IO-Link sensors which will continually record your data.

The pump data is then analyzed and sent to your location-independent devices. That means you can access the sensor data from anywhere and will be informed immediately in case of deviations.