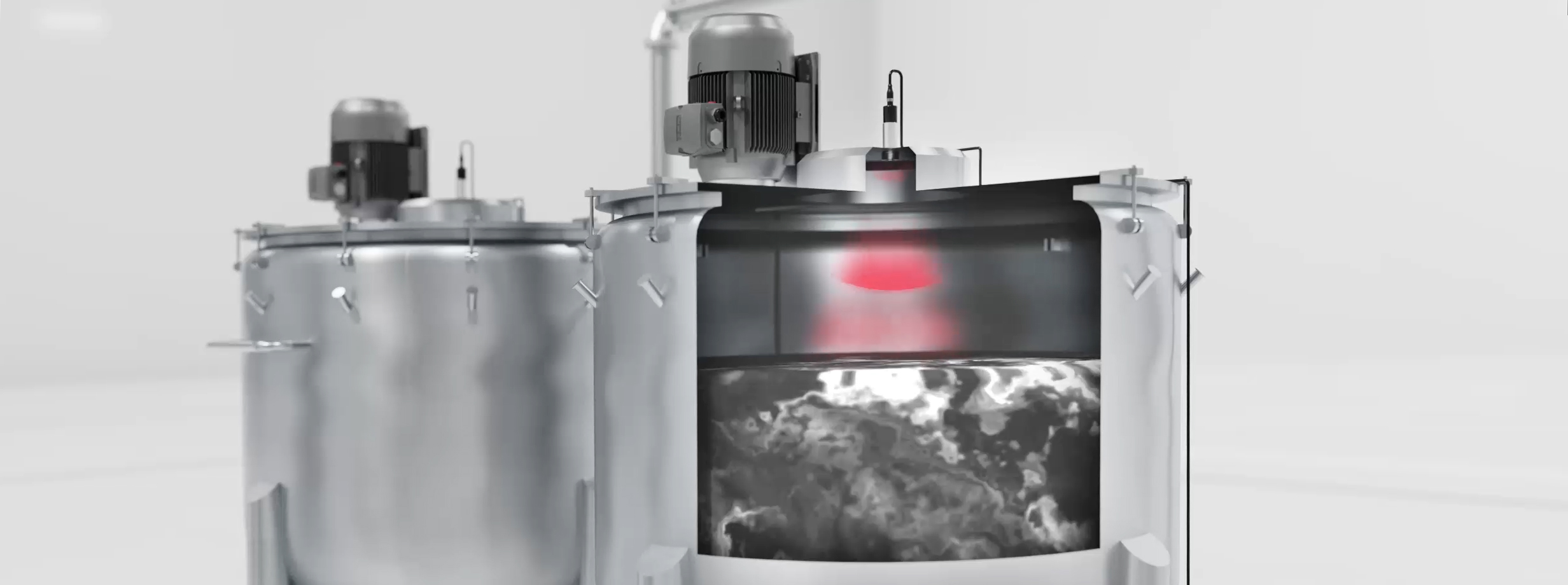

Detecting fill levels in slurry tanks with ultrasound

Ultrasonic sensors

Our ultrasonic sensors enable precise and efficient fill level detection in tanks during slurry mixing in battery production. They continuously record the fill level and transmit the data to the control system in real time. This enables optimum control and prevents overflows or material bottlenecks. The robust sensor technology guarantees reliable operation even in demanding environments, significantly increasing production quality and efficiency.

Features

- Precise fill level detection in real time with high accuracy, regardless of material color or surface texture

- Non-contact measurement of solid, powdery and liquid media without direct contact, minimizing wear and maintenance costs

- Reliable performance even in dusty, damp or aggressive environments thanks to chemically resistant materials and robust design

- Real-time data transmission to the control system to prevent overflows and material bottlenecks

- Extended functionality through IO-Link enables flexible parameterization and condition monitoring for optimized process control

Recommended ultrasonic sensors for level detection in slurry tanks

Ultrasonic sensors with analog output

- Style Housing

- Ø 12 mm

- Analog output

- Analog, voltage 0…10 V

- Connection

- Connector, M12x1-Male, 4-pin

- Housing material

-

Nickel-plated brass, nickel-plated

PBT - Material sensing surface

- PU foam/Epoxy resin/Glass

- Range

- 20...250 mm

- Approval/Conformity

-

cULus

CE

WEEE

UKCA - Ambient temperature

- -25...70 °C

- IP rating

- IP67

- Repeat accuracy

- ± 0.15 %FS

- Operating voltage Ub

- 15...30 VDC

High-pressure-resistant ultrasonic sensors

- Style Housing

- Ø 47 mm

- Process connection

- G 1"

- Analog output

- Analog, voltage/Analog, current 0…10 V/4…20 mA

- Switching output

- PNP normally open/normally closed (NO/NC)

- Connection

- Connector, M12x1-Male, 5-pin

- Housing material

-

1.4571 stainless steel

PBT, TPU - Material sensing surface

- PTFE

- Range

- 85...1500 mm

- Switching frequency

- 9 Hz

- Approval/Conformity

-

cULus

CE

WEEE

UKCA - Ambient temperature

- -25...70 °C

- IP rating

- IP67

- Repeat accuracy

- ± 0.15 %FS

- Pressure rating max.

- 6 bar

- Operating voltage Ub

- 9...30 VDC