- Sensor and networking excellence for Packaging, Food, Beverage, Pharma, and Personal Care industries

- Automation in the semiconductor industry

- Life Science

- Mobile Equipment

- Steel and Metallurgical Industry

- Drive Technology

- Metalworking

- Fluid Power Technology

- Advancing battery manufacturing automation: achieving superior efficiency and quality

- Automobile industry and suppliers

- Energy Production

- Plastic Industry

- Intralogistics automation: improve efficiency and throughput

- White goods

- Electronics industry

- Tire Industry

- Traffic Engineering

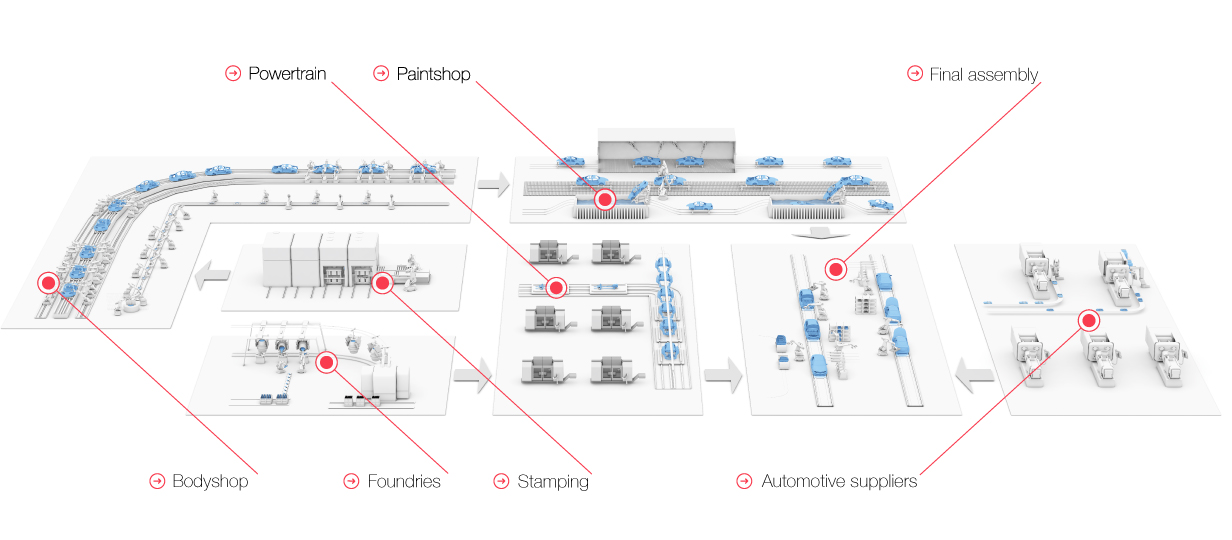

Automobile industry and suppliers

We offer you decades of experience and expert partnership

Balluff stands for high-value sensor, identification, networking and software solutions. Our comprehensive product range, solid development know-how and long years of experience in the automobile industry have made us a leading solutions provider for all areas of vehicle construction and all supplier branches.

From initial stamping to welding, painting, forging and casting to final assembly – we know every area down to the finest details. We make it possible for you to perform reliable quality control and ensure a smooth-running process during production, through assembly and beyond. Because we also ensure that every externally produced product is the highest quality and ready at the right time and in the right place, we are able to support your just-in-time deliveries.

You can rely on our partnership wherever you are manufacturing. We have a local presence everywhere in the world. And our sensors, systems, network and connectivity technology have international approvals and certifications.

Automotive Interior: Just-in-time delivery at the ready

The interior of a vehicle of tomorrow will be strongly influenced and changed by the new megatrends in mobility: Electromobility is creating new construction and design freedoms for vehicle interiors. And if autonomous driving becomes prevalent, other uses will open up for the occupants, as there will be no need to steer the car. These new uses would transform the interior into an experience space and could become a distinguishing feature of car manufacturers. New seating concepts are being designed and smart surfaces and innovative cockpit concepts are gradually taking hold.

No matter how these trends change your production facilities, Balluff supports your future-oriented production with sustainable products. As a long-standing partner of the automotive industry, we offer high-quality sensor, identification and network solutions and software for your plants. In addition, you benefit from our extensive experience, which has been proven in practice in all areas of automotive production. Rely on our expertise to meet the high expectations of your end customers in terms of quality, process reliability and efficiency and to guarantee smooth just-in-time delivery.

Powertrain

The powertrain determines how good and reliable a vehicle will eventually be on the road because the powertrain is where the vehicle's power is generated. All the more important for you to maintain your quality in this production phase. This can be done using Balluff's comprehensive expertise. Our products have been used successfully for decades wherever motor, transmission, axles and controller come together in various configurations in the powertrain.

Foundries

Lengthy temperature loads and short-time maximum temperatures as well as shock and vibration can, in foundries and forges result in significant performance reduction or even complete failure of the sensors. Balluff sensors are specifically designed for high temperatures. They are also available with heat-resistant accessories. Our products are HALT tested to ensure long service life. This means we are able to offer long-term, stable solutions. Our sensors minimize spare part requirements, reduce downtimes and substantially lower your costs.

Stamping

Production in a press plant is precision work and places high demands on equipment and logistics. Coils weighing tons are cut into sheet metal plates which are formed into body parts in highly automated stamping and forming processes in huge press lines. Different sheet metal thicknesses become side frames, hoods, doors and much more.

Sensor solutions from Balluff are designed for extremely demanding production conditions. These enable exact positioning and control as well as reliable identification of die cutters and workpieces. Our products can be used anywhere in the world. Because they have proven themselves in press plants all over the world.

Bodyshop

Industrial robots are an integral part of Bodyshop. Around the clock they fit individual components together into self-supporting bodyshells by means of welding, riveting and gluing – with the highest precision, greatest possible repeat accuracy and absolute reliability.

The especially rugged solutions from Balluff are also absolutely reliable. Tailored for Bodyshop, they are indifferent to weld splatter, welding currents, magnetic fields and high temperatures.

Paintshop

In the paintshop perfection and precision are the goal – even more so than at other stations, because the paint is responsible for the overall outer impression of the vehicle. At the same time it serves to protect and hold the value of the vehicle.

This makes it all the more important that you ensure, all the various process steps are performed smoothly and with the highest quality. Our solutions make this happen, because our sensors are highly resistant to temperatures and chemicals, so that your robots can apply the five layers perfectly with the help of the high-speed electrostatic rotary bell sprayers – right after the body shell has been cleaned and degreased in the dipping process.

Final assembly

To securely handle the complex steps in final assembly, we offer just the right product technologies and configurations. Such as for exact motion control, logging of sequences, or for reliable identification.

We offer high-value solutions which we customize to your special requirements – just like the individual trim levels and engine options of the vehicles themselves. This provides you with a reliable classification system and guarantees reliable processes in the provision of the individual parts so that you finish the painted bodyshells with the needed parts in the correct quantity and type. Using our technology you execute your customer assembly orders with perfection.

Tire Industry

High process security at every stepDownloads

-

Industry brochure automotive

Products

Products