- Matrix Vision solutions now all under the Balluff brand

- IO-Link: Intelligent solutions for modern automation

- Smart Automation and Monitoring System

- Comprehensive components and solutions for automated welding

- Architects of Smart Manufacturing

- High Durability

- Quality Assurance

- Explosion Protection

- Level Detection

- Miniaturization

- MicroSPOT

- Condition Monitoring

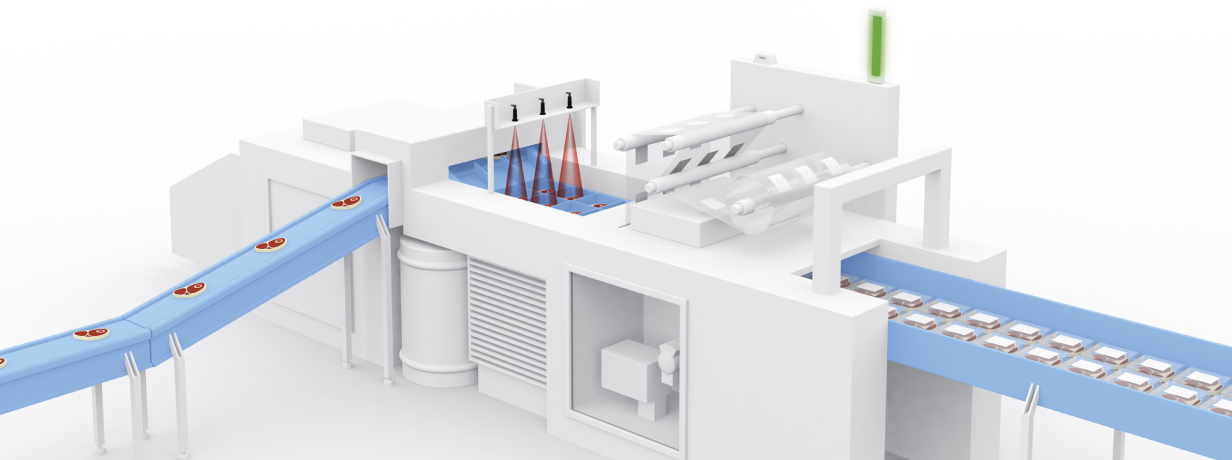

Identification of manufacturing and processing errors

Identification of manufacturing and processing errors

Identifying manufacturing and processing errors as early as possible is essential for high productivity. Continuous checks during the production or packaging process are critical here. They prevent lost batches and lower your costs.

Continuous checks keep products that do not meet quality standards from making it as far as filling, packaging or shipping. Rather, products can be improved or discarded. You will not need to initiate a recall action, and you will prevent your image from being damaged.

The quality assurance improvements you can get from Balluff consist of a wide range of solutions that reliably monitor your products and processes. We use a variety of technologies to meet your needs. For example, our RFID systems ensure continuous traceability throughout the process chain, starting from the raw material delivery, on to processing and packaging, and all the way to the consumer. To do this, we provide you with a broad range of data carriers, read/write heads and processor units that use HF (high frequency) and UHF (ultra-high frequency).

Our vision products offer another solution. You can ensure high product quality and guarantee food safety with industrial image processing. Our cameras — both industrial and Smart Cameras — unambiguously identify manufacturing and processing errors. The BVS Cockpit software is a user-friendly, versatile, and reliable image processing program. It lets you intuitively configure and operate Balluff SmartCameras and industrial cameras with a SmartVision controller, or with any machine vision system compatible with Gencam in your facility.

Solutions for product and process control

Optimize product quality and process through traceability

If you want to monitor all of the materials being used as well as all of the production steps, self-controlling systems are ideal. An RFID system can record and document all the data and ensure that each production step and every material being used is traceable. This information is available for you in real time, ensuring that if corrections are needed, they can be made during the process. RFID enables comprehensive transparency, so you can achieve excellent product quality and optimize your processes at the same time.

Accurate allocation of raw materials

To ensure that they can be accurately allocated, raw materials must be identified and recorded before being delivered. This can be done using the PDF417 codes found on raw materials. Since these codes are in different locations and are frequently not positioned at a uniform height, stationary readers are not very useful.

On the other hand, our BVS HS-P handheld scanners allow you to scan these codes easily wherever they are located. They can read all common 1D, 2D and stacked barcodes from documents, plastic labels, circuit boards and metal parts. These robust readers are ergonomic and give you an extremely high read performance.

Quality assurance with asset monitoring

During chocolate production, in order to ensure that the chocolate molds remain intact during use, you can use RFID to check them and replace them at the ideal time. This is because RFID reliably identifies your chocolate molds so you can simultaneously evaluate their status. The Mold-ID system, ur RFID-supported software solution developed for this purpose, records the throughput time as well as frequency of the washing processes and compares them to empirically-determined limit values for mold wear. In this way, you can find out the status of your assets whenever you choose, and you can remove worn-out molds from circulation. Asset management with RFID prevents production rejects and provides you with data that you can evaluate for the efficient use of your operating materials.

Product and process control in filling plants

Ensure an efficient and error-free filling process using our BLA light array. It reliably monitors the height and diameter of bottles in your filling plant. First, the high-resolution light array detects the width of the bottle neck, comparing it to values to that have been taught or set. Second, the correct cap is checked. Then another light array checks whether the cap is sitting flush on the bottle based on the bottle height. As a result, you are on the safe side, both in terms of product verification and process control.

Verify data and serial numbers in the packaging process

Speed is the name of the game, especially where packaging is concerned. Manufacturing and expiration dates for perishable foodstuffs, in addition to serial numbers, have to be assigned quickly and reliably. Vision solutions from Balluff make all this possible. Thanks to visual identification, you can reliably verify all typical 1D and 2D barcodes as well as all stacked codes. Our solutions for industrial image processing open up a wide range of applications for you. In addition, you can operate them intuitively. This makes them highly user-friendly and exceptionally efficient as a result.