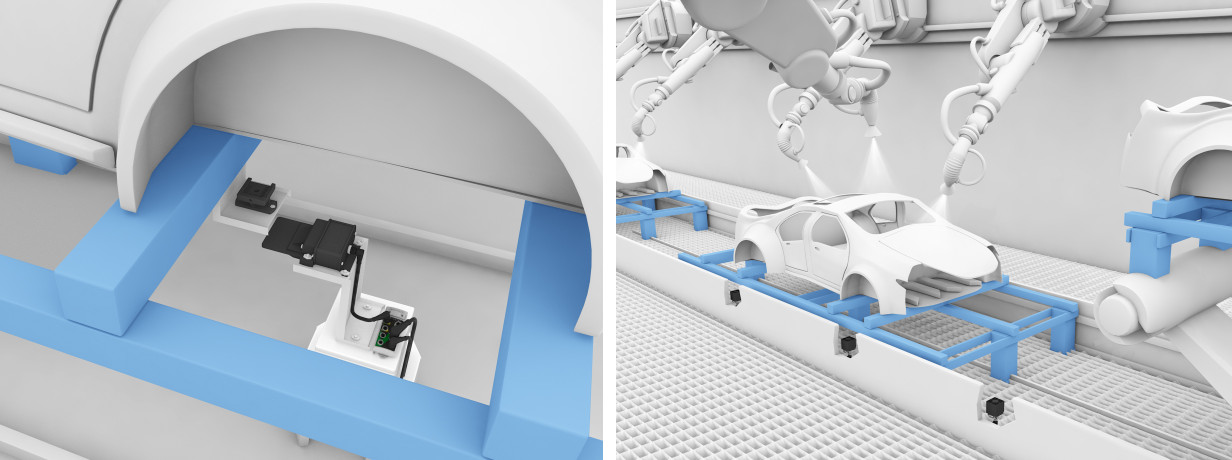

Automated handling and assembly technology in large conveyor systems

Conveyor system up to 1m object size

Automated machining and assembly processes ensure process reliability and the highest quality, as every step and every part can be traced. In large conveyor systems, for example car body production in the automotive industry, it is necessary to automatically guide the carriages through the production process - from the base coat to the homogeneous paint application of the atomizer to the subsequent drying.

With industrial RFID systems, it is possible to document the information of all work steps even under demanding environmental conditions and to guide the car bodies automatically through production. The RFID system BIS M has RFID frame antennas which, together with the read/write head electronics, are simply connected to our high-performance BIS V evaluation units. Due to the large reading range, these antennas are particularly suitable for conveyor systems from a width of approx. 500 mm. Data transmission succeeds without problems even at large distances and in motion. Special data carriers are designed for use in extreme environments, so that even production steps with temperatures above 200°C can be handled safely. This makes this RFID solution particularly suitable for long reading ranges and extreme environmental conditions.

- Different RFID frame antenna designs for different reading ranges

- High-temperature data carriers in various designs and memory sizes

- High performance due to universal evaluation unit BIS V, available for all common bus systems