Ultrasonic sensors

The accurate all-rounder

Whether position detection, distance measurement or the detection of solid, powdery and liquid media - our ultrasonic sensors are precise all-rounders.

They measure fill levels, heights or sagging without contact, monitor presence and count objects. Universally applicable, they work regardless of color and surface texture. Unaffected by transparent objects with strong reflections. Even fog, dust or dirt are no problem for them.

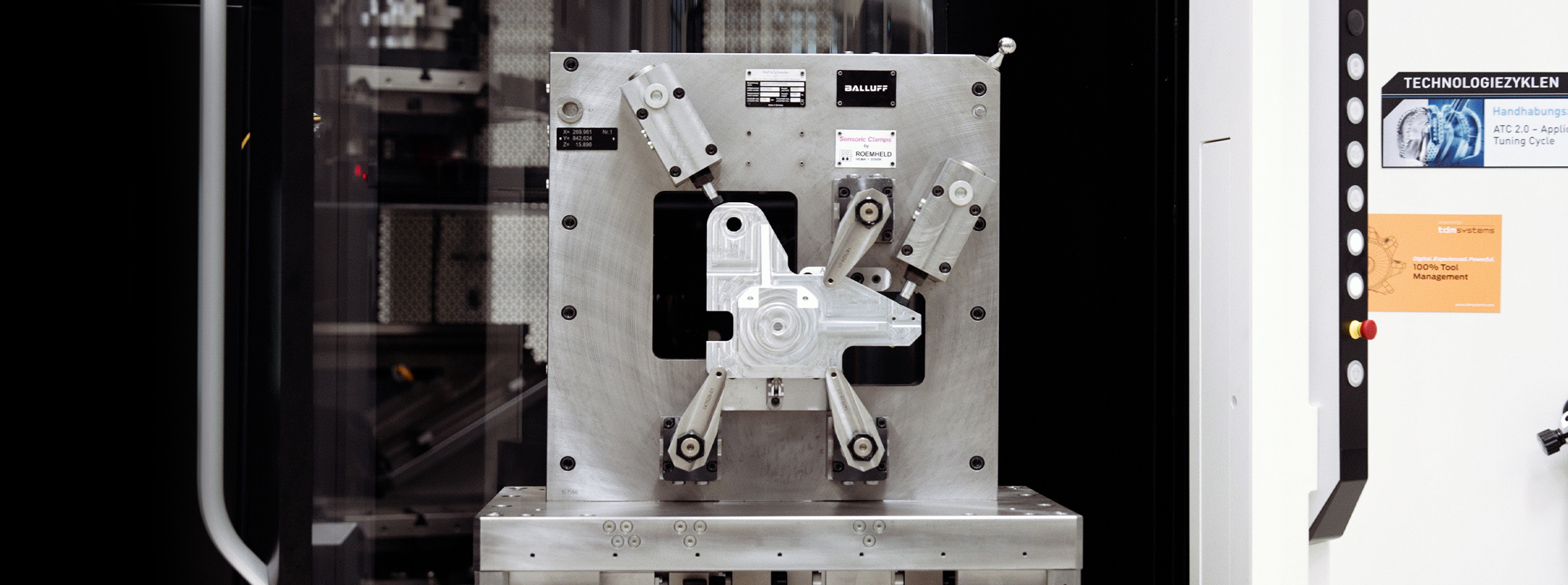

With the media-contacting ultrasonic position sensor, we are expanding our portfolio with an innovative option for the direct monitoring of hydraulic short-stroke cylinders. A reliable and economical solution for workpiece clamping - and a real milestone in the field of metalworking.

Our extensive portfolio of ultrasonic sensors

Ultrasonic sensors with analog output or digital output

Pressure-rated ultrasonic sensors

Ultrasonic sensors for short-stroke hydraulic cylinders

Their high resolution and small blind zones ensure extreme precision. And thanks to the large detection range, even large object distances are no obstacle for them.

Ultrasonic sensors from Balluff differ in their output signal. Thanks to a switching and an analog version, they can reliably detect and count objects as well as determine distances with high precision. This guarantees a wide range of applications.

Another plus: thanks to various output functions, our ultrasonic sensors can be used as normally closed or normally open contacts.

The most important advantages

- Non-contact detection

- Reliable in critical environmental conditions such as dirt, dust or fog

- Independent of the color, transparency, reflective properties and surface characteristics of the object

- Precise detection of even small objects

- cuboid and cylindrical designs provide more design freedom

Product guide for object detection

Tell us what your requirements are and we will tell you which product you need!Application examples

Application examples from various industrial sectors demonstrate the wide range of uses for ultrasonic sensors. They reliably detect distances, fill levels and objects - regardless of color, transparency or surface. Thanks to their non-contact and wear-free measuring principle, they are extremely precise and stable, even under harsh environmental conditions such as dust, dirt or moisture. They therefore offer flexible solutions for industrial automation and guarantee consistently high measuring accuracy.

-

Intralogistics: avoid collisions

-

Plastics industry: Keeping a constant eye on the fill level

-

Tire industry: Process reliability through tire detection

-

Metalworking: Checking sheet metal strip sagging

-

Steel and metallurgical industry: Sheet metal feeding for the coil

-

Battery industry: Monitoring material availability with ultrasonic sensors

Innovation in focus

Ultrasonic position sensor directly monitors workpiece clamping

A milestone in the field of metal processing