Continuously monitor production steps

SmartLight for clear process visualization

Cathode and anode active materials are stored in tanks before they enter the mixer. If you need seamless visualization of the processes in your production line, the SmartLight signal light is the perfect solution. The SmartLight shows trends and patterns so that you can continuously monitor various production steps. The different modes - running light, level, segment and flexi - can be set without mechanical changes. By programming them, you can choose between running light and color gradient or the display of up to five color segments.

Features

- Extremely flexible: Can be changed during operation without mechanical reconfiguration

- Easy to install and retrofit anywhere

- Retrofittable

- Multicolored, bright LEDs with a wide color spectrum, individually definable

- With IO-Link for ideal use in IIoT

Recommended smart lights and machine lighting for visualizing production processes

Machine lighting

- Connection

- Connector, M12x1-Male, 4-pin

- Version

- Machine light

- Dimension

- Ø 45 x 420 mm

- Rated operating voltage Ue DC

- 24 V

- Material

-

Aluminium Anodized

Borosilicate crown glass - Illumination area

- 380 x 42 mm

- Beam angle

- 120 °

- Light type

- LED white light diffuse

- Light intensity

- 1450 lm

- Color temperature

- 5000 K

- Ambient temperature

- -20...40 °C

- Approval/Conformity

-

CE

UKCA

cULus

WEEE - IP rating

- IP67

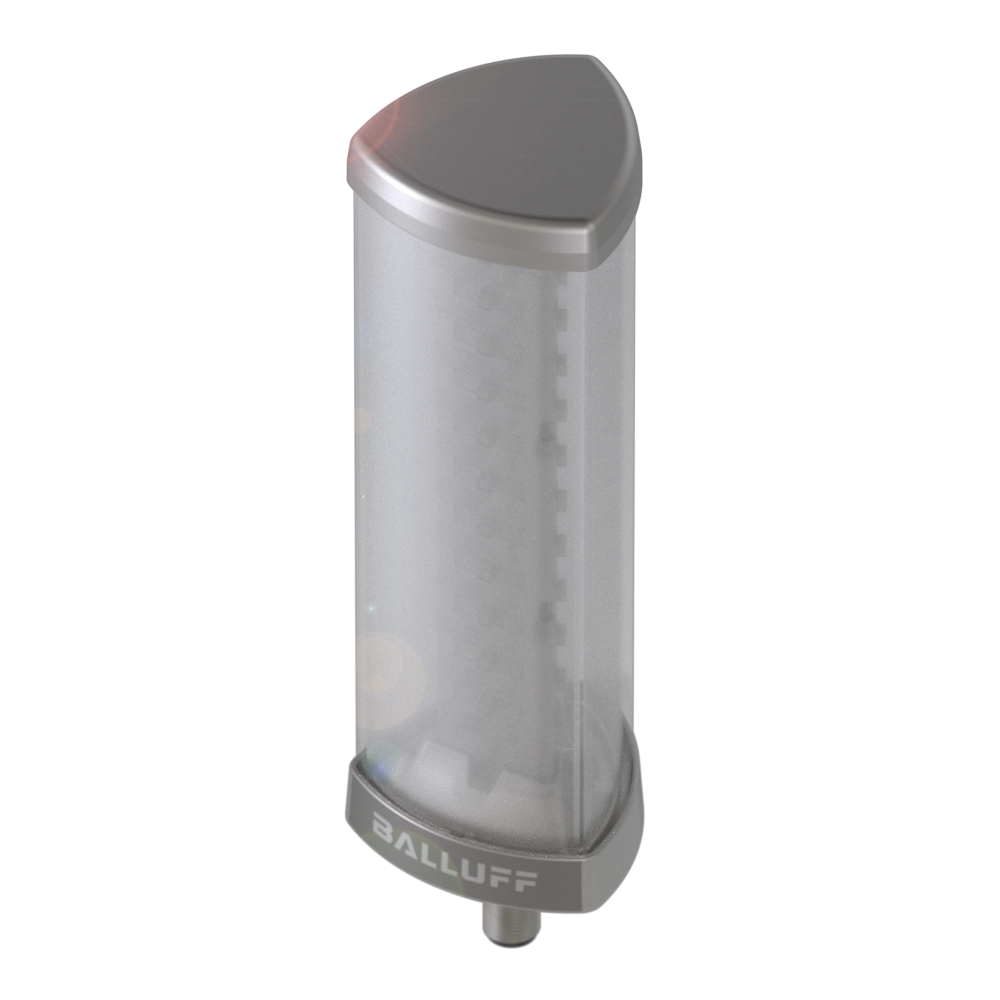

Smart LED signal tower with different numbers of segments

- Principle of operation

- Indicator light

- Interface

- IO-Link 1.1

- Operating voltage Ub

- 18...30.2 VDC

- Connection

- M12x1-Male, 4-pin

- Segments, number max.

- 3

- Predefined colors

-

yellow

white

green

Blue

red

orange

configurable - Function indicator

-

Runlight Mode

Level Mode

Segment Mode

Flexi-Mode - Setting

- Function indicator

- Additional function

- Expanded process data

- Dimension

- 60 x 60 x 213 mm

- Housing material

-

PC, Transparent, Cu 15 µm, Ni 15 µm

Die-cast zinc - Mounting part

- Screws M18

- Ambient temperature

- -5...50 °C

- IP rating

- IP65

- Transfer rate

- COM2 (38.4 kBaud)

- Process data cycle min.

- 7.2 ms

- Process data IN

- 1 byte

- Process data OUT

- 8 bytes

Compact LED signal light with 6 segments and IP67

- Principle of operation

- Indicator light with sound module

- Interface

- IO-Link 1.1

- Operating voltage Ub

- 18...30.2 VDC

- Connection

- M12x1-Male, 4-pin

- Segments, number max.

- 3

- Predefined colors

-

yellow

white

green

Blue

red

orange

configurable - Function indicator

-

Runlight Mode

Level Mode

Segment Mode

Flexi-Mode - Volume (at a distance of 1m)

- 95 dB/m

- Setting

-

Function indicator

Volume - Additional function

- Expanded process data

- Dimension

- 60 x 60 x 234.5 mm

- Housing material

-

PC, Transparent, Cu 15 µm, Ni 15 µm

Die-cast zinc - Mounting part

- Screws M18

- Ambient temperature

- -5...50 °C

- IP rating

- IP30

- Transfer rate

- COM2 (38.4 kBaud)

- Process data cycle min.

- 7.2 ms

- Process data IN

- 1 byte

- Process data OUT

- 8 bytes

IO-Link control panel

- Principle of operation

- IO-Link control panel, 4-way

- Dimension

- 85 x 64 x 199 mm

- Ambient temperature min.

- -5 °C

- Ambient temperature max.

- 55 °C

- Approval/Conformity

-

CE

WEEE

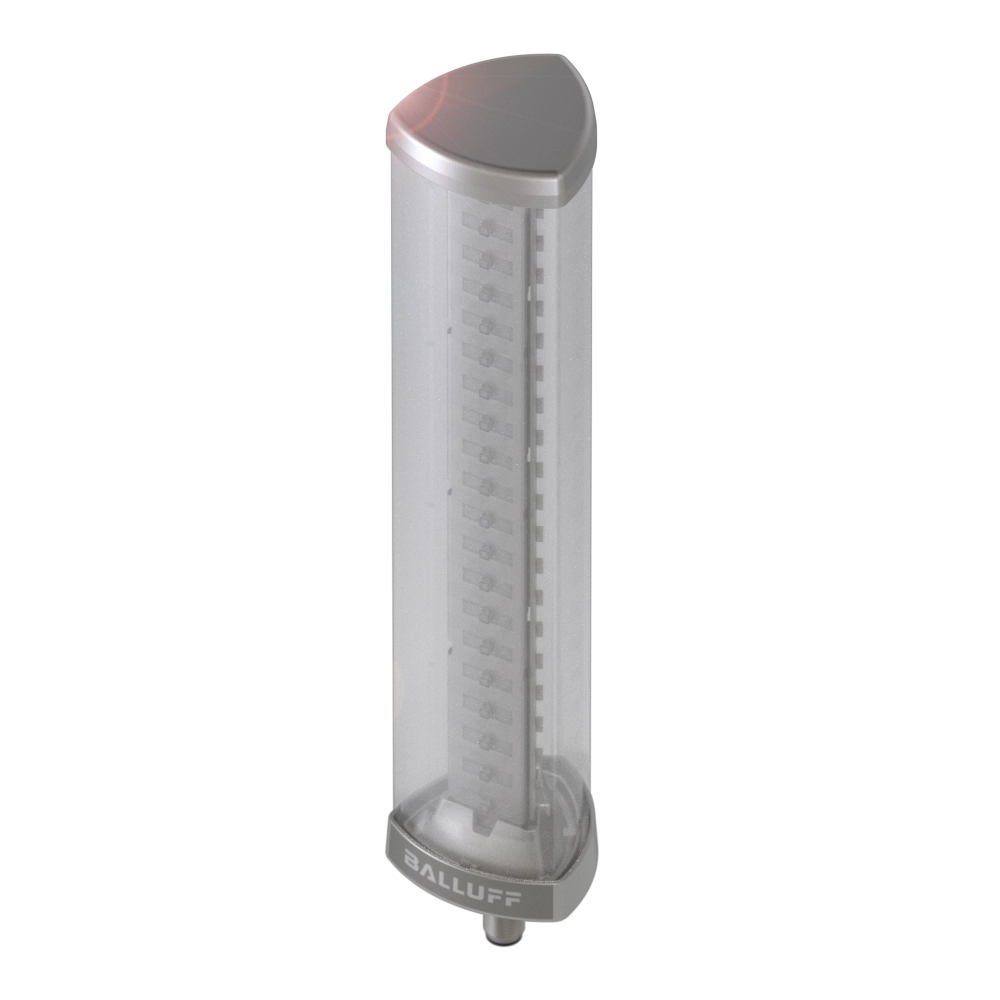

Smart LED signal towers with different numbers of segments

- Principle of operation

- Indicator light

- Interface

- IO-Link 1.1

- Operating voltage Ub

- 18...30.2 VDC

- Connection

- M12x1-Male, 4-pin

- Segments, number max.

- 5

- Predefined colors

-

yellow

white

green

Blue

red

orange

configurable - Function indicator

-

Runlight Mode

Level Mode

Segment Mode

Flexi-Mode - Setting

- Function indicator

- Additional function

- Expanded process data

- Dimension

- 60 x 60 x 309 mm

- Housing material

-

PC, Transparent, Cu 15 µm, Ni 15 µm

Die-cast zinc - Mounting part

- Screws M18

- Ambient temperature

- -5...50 °C

- IP rating

- IP65

- Transfer rate

- COM2 (38.4 kBaud)

- Process data cycle min.

- 7.2 ms

- Process data IN

- 1 byte

- Process data OUT

- 8 bytes

Further application examples in the field of slurry mixing

Discover more topics

Downloads

-

Industry brochure battery industry