Not just "click clack"

More helpful data through condition monitoring

Industry:Special machine builder - Forging industryCustomer:Jerko Sprühsysteme GmbH

More helpful data through condition monitoring. "Condition monitoring and avoiding unplanned downtimes are becoming increasingly more important to us and our customers," explains Niklas Dahmen, Managing Director at Jerko Sprühsysteme GmbH, adding: "That's why we asked ourselves how we can collect more useful data from our equipment - without any extra effort."

Situation

The supply of spray equipment and systems plays an important role in machine uptime. If defects occur due to contamination, wear, or blockages in the pipe, the systems come to a standstill. "Our goal was to stabilize the process reliability when supplying the equipment by use of a pneumatic piston pump by providing an increased amount of useful data. The additional information will be used for predictive maintenance and targeted condition monitoring," says Dahmen.

Challenge

Based on individual customer requirements, Jerko Sprühsysteme builds one-of-a-kind spraying systems for the forging and metalworking industry. These systems range from small, manually operated spraying devices all the way to fully automated robots and manipulators designed to safely handle heavy loads.

An unplanned shutdown or failure of the systems would significantly disrupt the synchronized production process of thermally sensitive components and cause high costs when restarting. And this is exactly what needs to be avoided.

Solution

A solution using sensors from the Smart Automation and Monitoring System (SAMS) proved to be ideal. In addition to process data, operating data such as temperature, hours in operation, number of strokes, signal quality, and vibration will be captured and transmitted using these sensors.

"The signal quality, for example, provides information about the machine environment. It declines when sensors are contaminated. And the vibration figures show whether all the mechanics are working as intended," Dahmen explains the additional features. This significantly improves condition monitoring. And the data all comes from a standard "click-clack" sensor.

How does it work?

The BES05Y7 sensor used was installed in the piston pump and, thanks to the integrated additional functions, now reliably recognizes whether the process is as it should be.

Far more than a standard sensor ever could.

Is the temperature still correct? Is the vibration profile OK or is there any sign of wear? How many strokes has the pump made? This and other information is transmitted to the control system via IO-Link and provides an exact and timely insight into the status of the system. And all this without expensive special sensors - but simply where the classic standard sensor would otherwise be installed.

Thanks to Balluff's support, we fully achieved our goal to get a lot of useful data into the system with little effort. We now know things about our machines that we didn't know before, which will be tremendously useful with follow-up projects.

Niklas Dahmen, Managing director Jerko Sprühsysteme GmbH

Advantages

Using the new SAMS-capable components gives you a few more advantages in your production:

- Know what's happening - not just click-clack

- Avoid unplanned downtime

- Plannability of system service

- Increased system availability - Higher OEE

- Simple integration into existing systems

Products

In order to make optimum use of these functions and benefits, the existing IO-Link system was simply expanded with the smart standard sensor.

Condition monitoring sensors

- Function

-

Vibration analysis in time domain

Contact temperature monitoring

Relative Humidity

Ambient Pressure - Vibration, frequency range

-

2…1800 Hz (±10 %)

2…2500 Hz (±3 dB) - Vibration, number of measuring axes

- 3

- Vibration, measuring range

- -16…16 g

- Contact temperature, measuring range

- -25…+70 °C

- Relative humidity, measuring range

- 5...95 %RH

- Ambient pressure, measuring range

- 300…1100 hPa

- Rated operating voltage Ue DC

- 24 V

- Interface

- IO-Link 1.1

- Connection

- Cable with connector, M12x1-Male, 3-pin, 1.5 m, PUR

- Housing material

- 1.4404 stainless steel, Membrane: ePTFE with nylon fleece

- IP rating

- IP67

- Ambient temperature

- -25...70 °C

Inductive proximity switches and proximity sensors

- Special characteristics

-

Washdown Plus

Washdown - Dimension

- Ø 12 x 65 mm

- Style Housing

- M12x1

- Installation

- quasi-flush

- Range

- 0.5...4 mm

- Interface

- IO-Link 1.1

- Switching output

- PNP/NPN/push-pull NO/NC;Push-pull NO/NC

- Switching frequency

- 1000 Hz

- Housing material

- 1.4404 stainless steel

- Material sensing surface

- PBT

- Connection

- Connector, M12x1-Male, 4-pin

- Operating voltage Ub

- 10...30 VDC

- Ambient temperature

- -40...85 °C

- IP rating

- IP68, IP69K

- Secondary features

-

Identification

Device Discovery

Switching Profiles

Signal Quality Monitoring

External Signal Blanking

Signal Delay

Signal Speed Monitor

Switching Counter

Basic Statistics

Logic Blocks

Operating Hours Counter

Boot Cycle Counter

Voltage and Current Monitoring

Extreme Environment Status

Storage Usage Monitoring

Variant Configuration

Pin Assignment - Secondary features for condition monitoring

-

Vibration monitoring

Inclination monitoring and installation aid

Internal temperature monitoring

Internal humidity detection - Approval/Conformity

-

CE

UKCA

cULus

WEEE

Ecolab

Network blocks for Profinet

- Interface

- Profinet

- Interface IIoT

- REST API, MQTT parsed

- Auxiliary interfaces

- 8x IO-Link

- Port-class

- Type A

- Output current max.

- 2 A

- Fast Start-Up (FSU)

- yes

- Display

- no

- Operating voltage Ub

- 18...30.2 VDC

- Connection (COM 1)

- M12x1-Female, 4-pin, D-coded

- Connection (COM 2)

- M12x1-Female, 4-pin, D-coded

- Connection (supply voltage IN)

- 7/8"-Male, 5-pin

- Connection (supply voltage OUT)

- 7/8"-Female, 5-pin

- Connection slots

- 8x M12x1-Female, 5-pin, A-coded

- Digital inputs

- 16x PNP, Type 3

- Digital outputs

- 16x PNP

- Configurable inputs/outputs

- yes

- Current sum US, sensor

- 9.0 A

- Current sum UA, actuator

- 9.0 A

- Housing material

- Die-cast zinc, nickel-plated

- Dimension

- 68 x 37.9 x 224 mm

- Ambient temperature

- -25...70 °C

- IP rating

- IP67

- IO-Link version

- 1.1.3

- Safety Hub Support

- yes

Digital Position Indicators

- Display

-

Digital display

12 characters - Shaft type

- Hollow shaft

- Shaft diameter

- 20 mm

- Resolution rotary

- 14000 ppr

- Repeat accuracy

- ± 1 Inkrement

- Non-linearity max.

- ±1°

- Connection

- M12x1-Male, 4-pin

- Speed max.

- 600 1/min

- Interface

- IO-Link 1.1

- Housing material

- PA 12

- IP rating

- IP69K, IP68

- Secondary features

-

Identification

Device Discovery

Measurement Profiles

Signal Delay

Switching Counter

Basic Statistics

Logic Blocks

Operating Hours Counter

Boot Cycle Counter

Voltage and Current Monitoring

Extreme Environment Status

Storage Usage Monitoring

Variant Configuration

Pin Assignment - Secondary features for condition monitoring

-

Vibration monitoring

Inclination monitoring and installation aid

Internal temperature monitoring

Internal humidity detection - Approval/Conformity

-

CE

UKCA

cULus

Ecolab

WEEE

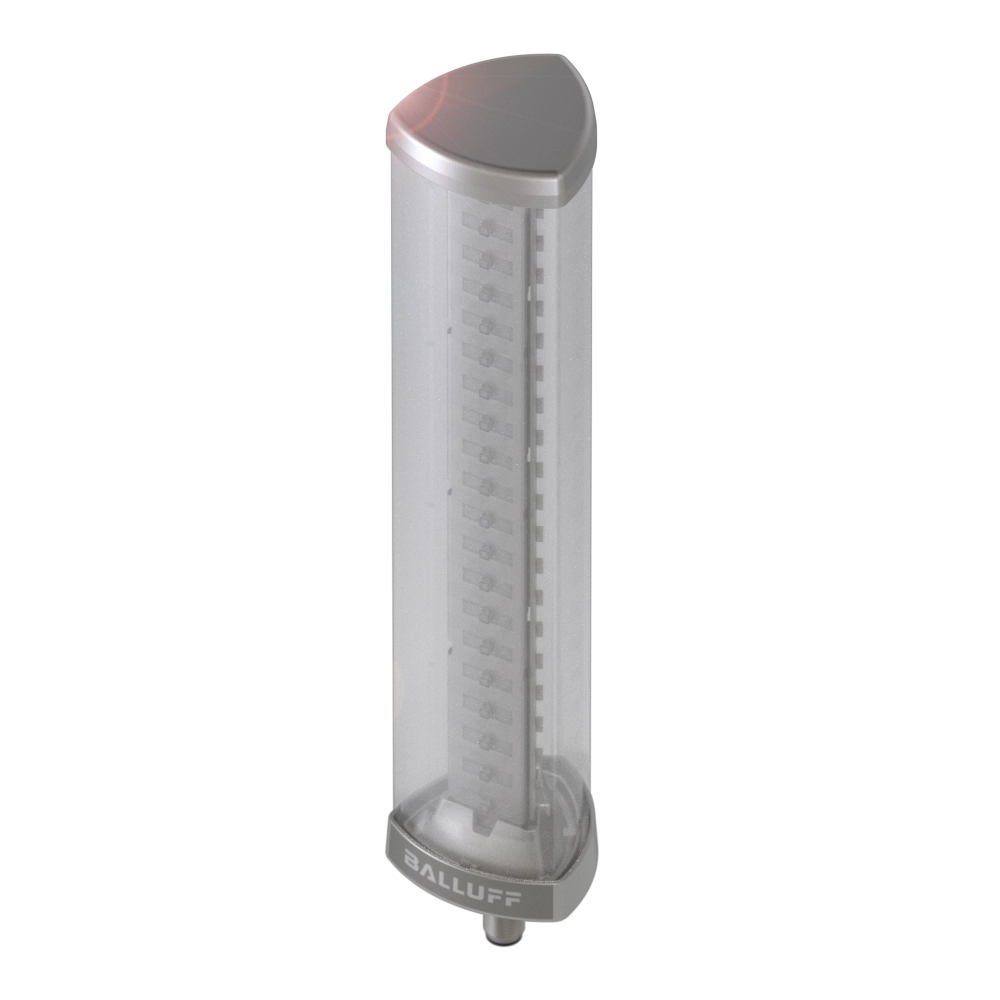

SmartLight - LED stack lights

- Principle of operation

- Indicator light

- Interface

- IO-Link 1.1

- Operating voltage Ub

- 18...30.2 VDC

- Connection

- M12x1-Male, 4-pin

- Segments, number max.

- 5

- Predefined colors

-

yellow

white

green

Blue

red

orange

configurable - Function indicator

-

Runlight Mode

Level Mode

Segment Mode

Flexi-Mode - Setting

- Function indicator

- Dimension

- 60 x 60 x 309 mm

- Housing material

-

PC, Transparent, Cu 15 µm, Ni 15 µm

Die-cast zinc - Mounting part

- Screws M18

- Ambient temperature

- -5...50 °C

- IP rating

- IP65

- Transfer rate

- COM2 (38.4 kBaud)

- Process data cycle min.

- 5 ms

- Process data OUT

- 3 bytes