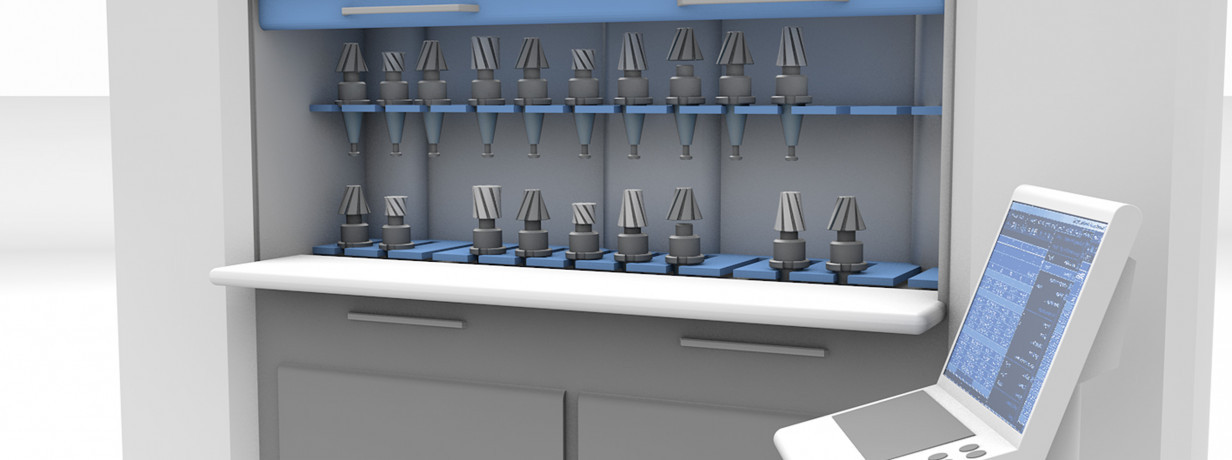

Consistent tool management: From tool identification to adjacent production areas

With isostandardized RFID system: Tool-ID BIS M

In modern production and assembly plants, RFID identification systems are used not only for tool identification for optimum tool management, but also for material flow control and handling tasks. This means that data must be reliably captured in harsh metal environments, while at the same time the objects move at high speeds during material flow control.

The high-frequency system (HF) is suitable for this combination of requirements. It scores with high transmission speed and large read/write distances. Due to the frequent use of HF RFID systems in industrial conveyor technology, this standard has become established. The use of a high-frequency RFID system in tool management enables the use of a universal RFID system in the entire tool management as well as the adjacent production areas.

- Robust and reliable identification in metallic environment

- High transmission speed

- Data carrier in standard size for Ø10mm bore in tool holders

- Decentralized data storage directly at the tool