Ultra-flat sensors for wafer production

Automation specialist Fabmatics relies on sensors from Balluff for handling solutions for semiconductor factories

Picture: Wafer on endeffector. Image source: © Fabmatics GmbH

Industry:SemiconductorCustomer:Fabmatics GmbH, Dresden, Germany

Fabmatics, headquartered in Dresden/Germany, is an experienced specialist for the automation of material flows and handling processes in semiconductor factories, semiconductor process plants and other high-tech production environments. Founded in 1991, the company has been successfully implementing customer-specific automation projects in the semiconductor industry for more than 30 years. This results in a strong market position, especially in the modernization of 200-millimeter semiconductor factories worldwide.

Situation

To detect substrates in handling systems for the semiconductor industry, very flat sensors usually have to be used in the end effectors in order to keep the contour of the end effector small. In the so-called wafer boxes, the individual - very valuable - wafers are only stacked very close together. The actual free space available for the end effector is also reduced by other influences. This results in end effector geometries that are sometimes only a few millimetres thick.

In addition to the requirement to generate as few particles as possible, it is also necessary to minimize contamination caused by outgassing of hydrocarbons from plastics, for example.

Challenge

The ever-increasing miniaturization of semiconductor components is leading to ever-increasing demands for the materials used to be free of contamination. This can only be achieved by selecting suitable materials. These general conditions mean that the sensors required to detect the presence of substrates must have an ultra-flat design without compromising on reliability or detection capability.

The size of the sensor and the materials used are therefore particularly important.

Solution

Balluff has a broad portfolio to meet this requirement. Thanks to decades of experience in the field of sensor technology, a suitable system was quickly found.

What's the solution?

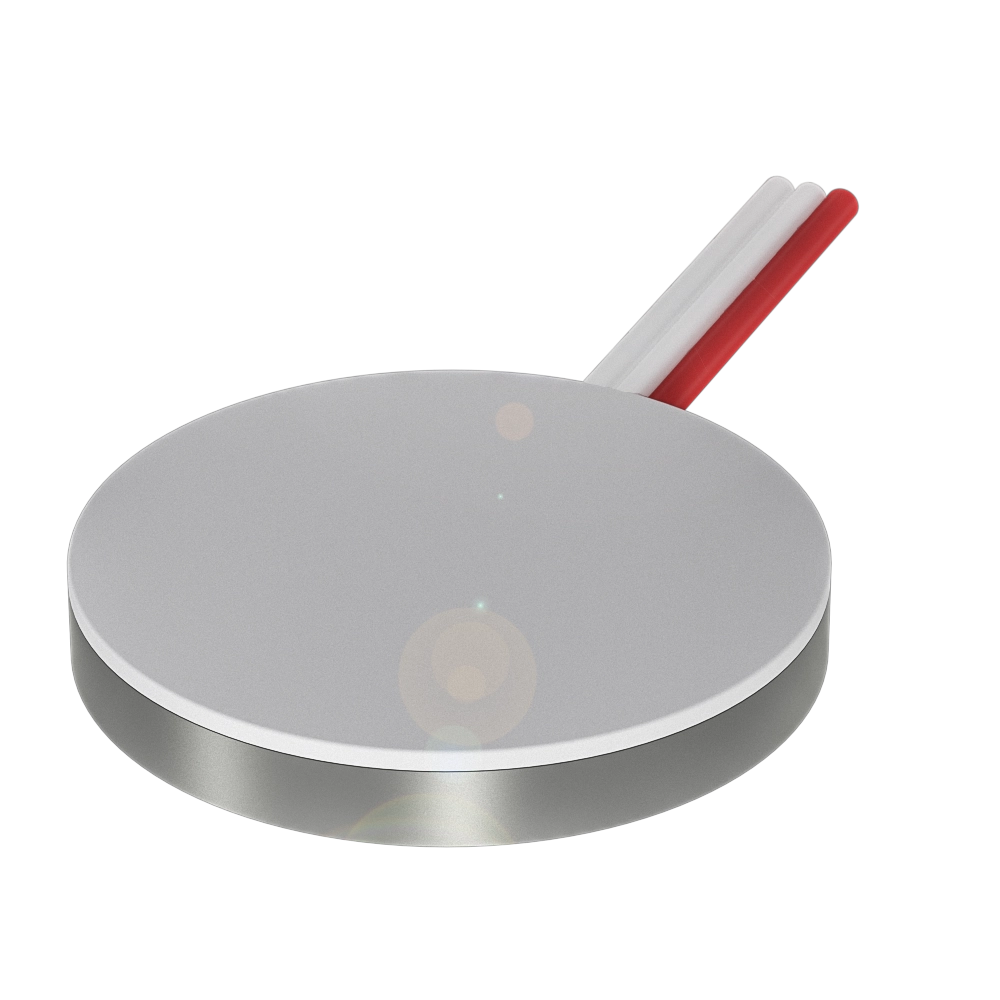

As an alternative to optical sensors, Balluff offers disc-shaped, very thin capacitive sensors. Such sensors offer the advantage of being independent of the surface of the material to be detected. This compact design enables the end effector to be designed as small as possible, thus ensuring compact and efficient material handling.

Balluff solves the challenge of preventing contamination through outgassing by using special materials such as stainless steel and Teflon® (PTFE) in the construction of these sensors. This guarantees outgassing-free use and enables smooth production.

What other benefits does the solution have?

In the specific applications, the end effectors are only 4.5 mm thick, of which the BCS00WY sensor itself only takes up 2.5 mm. Fabmatics opted for the sensor from Balluff because it is unique on the market with its combination of materials and extremely thin design. The sensor also scores points with its downstream amplifier, which can be housed far away from the sensor and enables a variety of different types of output signals (IO-Link, analog, digital). Balluff sensors that fulfill all of these requirements have been used successfully for many years by Fabmatics, a leading supplier of automation and robotics systems in the semiconductor industry. Fabmatics already supplies numerous robot systems with correspondingly thin end effectors in handling systems for a well-known German machine manufacturer in the semiconductor industry.

Image: End effector from Fabmatics with capacitive sensor from Balluff (white area), used in handling systems for loading semiconductor machines. Image source: © Fabmatics GmbH

Image: End effector from Fabmatics with capacitive sensor from Balluff (white area), used in handling systems for loading semiconductor machines. Image source: © Fabmatics GmbH

Image: Free-moving robot system -HERO Fab- from Fabmatics for transporting and handling wafer boxes. Image source: © Fabmatics GmbH

Image: Free-moving robot system -HERO Fab- from Fabmatics for transporting and handling wafer boxes. Image source: © Fabmatics GmbH

Benefits

- The sensor is very small - fits everywhere

- The sensor is outgassing-free - ready for semiconductor detection

- The electronics have an extra housing - saves space inside the machine

- The electronics can handle all common interfaces - analog, digital, IO-Link

- The combination of sensor and electronics is proven and robust - in use worldwide

Products

Fabmatics uses capacitive sensors to detect the wafer disks in the end effector. There are a large number of different variants and areas of application in this area. The use of switching amplifiers offers a major advantage. The sensor itself is very small, as the evaluation electronics are housed in an external housing - the switching amplifier. This can be housed in a switch box outside the detection area, thus saving valuable space in the system.

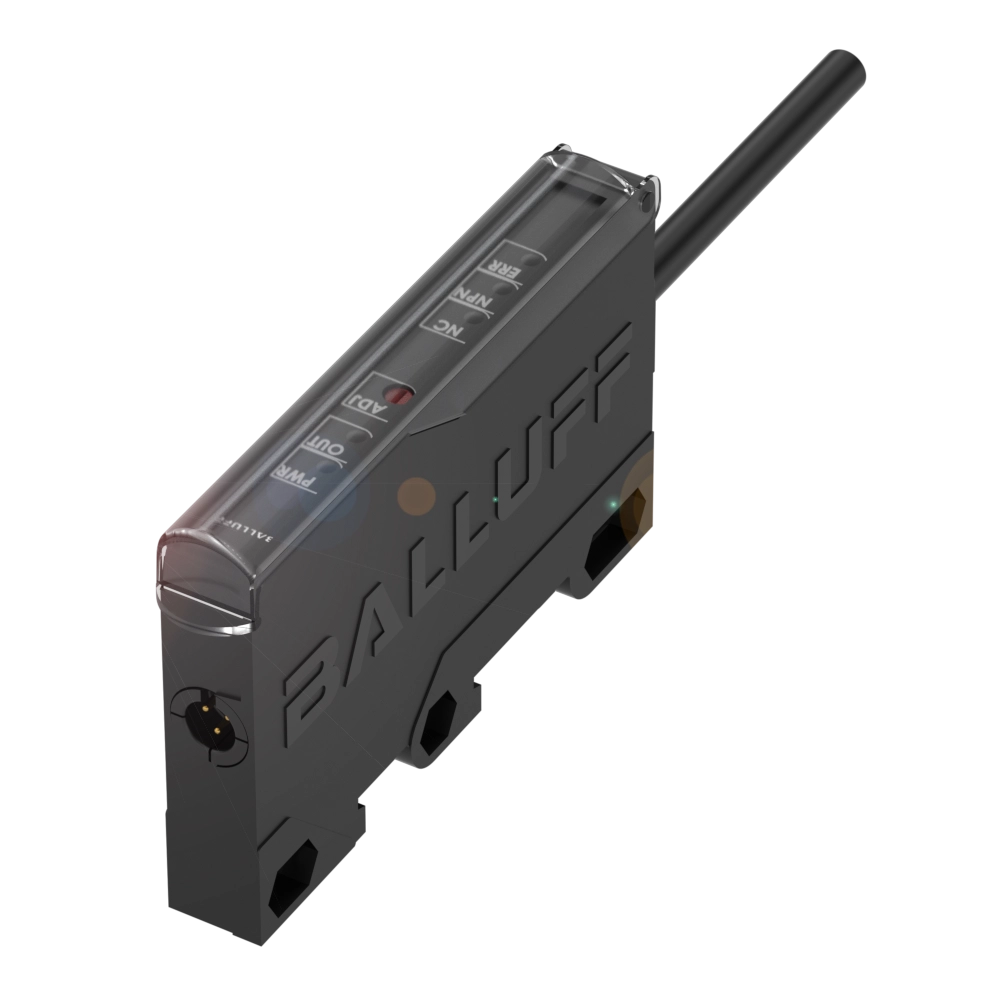

Amplifiers for capacitive sensor heads

- Dimension

- 10.5 x 45 x 75.5 mm

- Connection

- Cable, 2.00 m, PUR

- Switching output

- PNP/NPN NO/NC programmable

- Switching frequency

- 100 Hz

- Housing material

- PBT

- Ambient temperature

- -10...70 °C

- Operating voltage Ub

- 12...30 VDC

- Approval/Conformity

-

CE

UKCA

cULus

WEEE - IP rating

- IP40

Amplifiers for capacitive sensor heads

- Dimension

- 10.5 x 45 x 75.5 mm

- Connection

- Cable, 2.00 m, PUR

- Switching output

- PNP/NPN NO/NC programmable

- Switching frequency

- 100 Hz

- Analog output

- Analog, voltage/Analog, current 0…10 V/4…20 mA

- Housing material

- PBT

- Ambient temperature

- -10...70 °C

- Operating voltage Ub

- 15...30 VDC

- Approval/Conformity

-

CE

UKCA

cULus

WEEE - IP rating

- IP40

- Time function

- On/off delay time programmable

Amplifiers for capacitive sensor heads

- Dimension

- 10.5 x 45 x 75.5 mm

- Connection

- Cable with connector, M12x1-Male, 4-pin, 0.30 m, PUR

- Switching output

- PNP/NPN NO/NC programmable

- Switching frequency

- 50 Hz

- Interface

- IO-Link 1.1

- Housing material

- PBT

- Ambient temperature

- -10...70 °C

- Operating voltage Ub

- 18...30 VDC

- Approval/Conformity

-

CE

UKCA

cULus

WEEE - IP rating

- IP40

- Time function

- On/off delay time programmable

Capacitive sensor heads for amplifiers

- Dimension

- Ø 18 x 2.7 mm

- Series

- D18

- Installation

- for flush mounting

- Connection

- Cable, Special connector-Special connector, 2.00 m, PTFE

- Interface

- Special interface

- Range

- 0.1...3 mm

- Sensitivity

- adjustable on base unit

- Housing material

- 1.4301 stainless steel

- Material sensing surface

- PTFE

- Ambient temperature

- -30...70 °C

- Approval/Conformity

-

CE

UKCA

WEEE - IP rating

- IP66