- Matrix Vision solutions now all under the Balluff brand

- IO-Link: Intelligent solutions for modern automation

- Architects of Smart Manufacturing

- Smart Automation and Monitoring System

- Comprehensive components and solutions for automated welding

- Condition Monitoring

- Explosion Protection

- Level Detection

- Quality Assurance

- Tough Performers

- Miniaturization

Asset Management

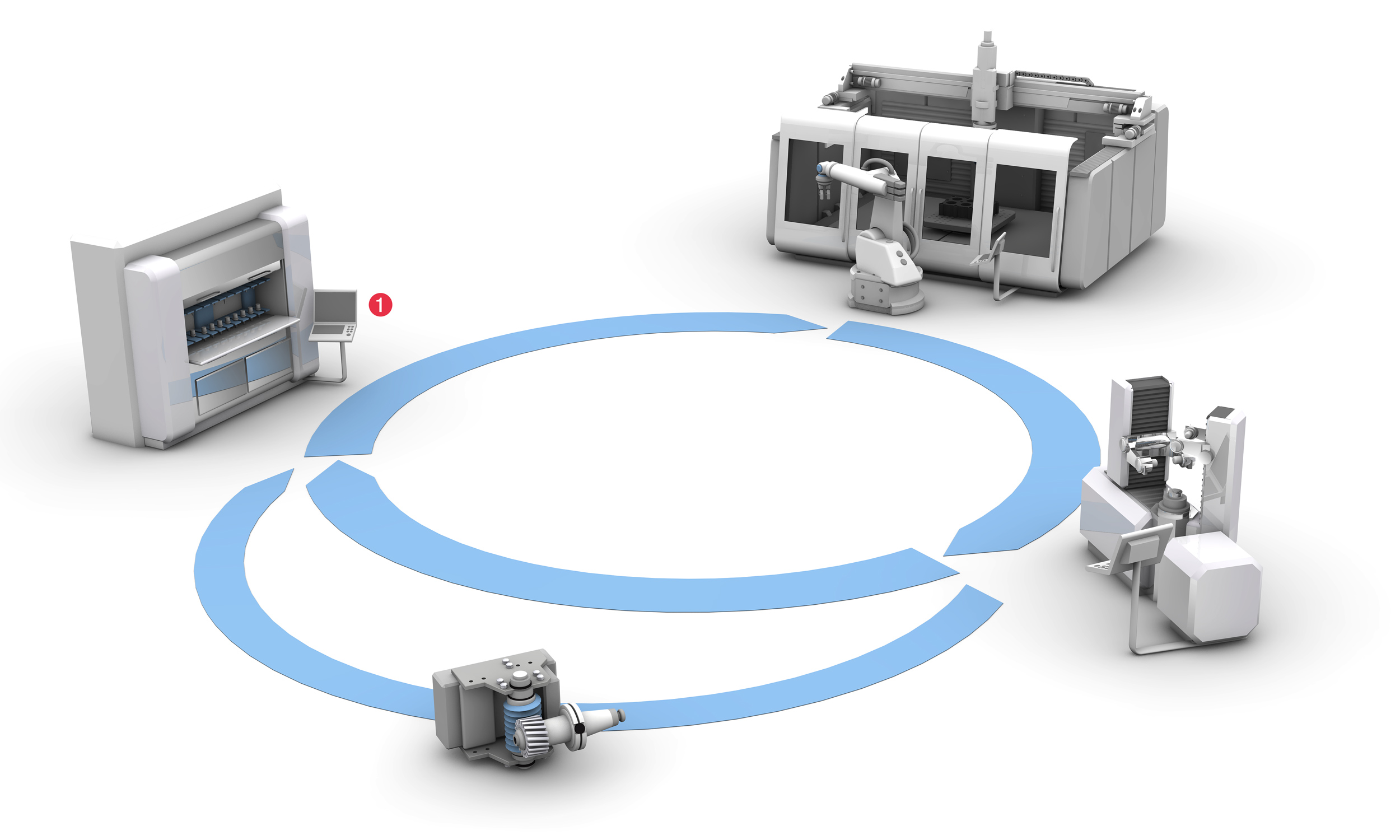

Ensure machine availability and plant operation

Efficient asset management supports high machine availability and reliable equipment with minimal stoppages. Maintenance effort is drastically reduced while increasing production flexibility.

Asset management solutions from Balluff provide you with reliable and always up-to-date information – using RFID as the key technology. For example, our tool management solutions eliminate error-prone, manually kept tool logs. In addition, our plug-and-play retrofittable versions for tool identification make optimal tool utilization easy. RFID also ensures unambiguous detection, matching and traceability of the produced workpieces.

Our 13.56 MHz HF system BIS M is an established standard. Learn about our reliable portfolio of solutions for your asset management.

Application example

(1) All tool data always available

(1) All tool data always available

BIS C RFID systems in LF or BIS M in HF from Balluff always provide the CNC controller in milling machines and machining centers with the correct tool data. Reliably identified and transmitted parameters form the basis for optimal tool management. Instead of error-prone, manually kept tool logs, the data is continually recorded when loading and unloading the tool so that continued use of the tool can be controlled. The actual tool dimensions are stored, for example, so that they can be automatically read into the tool table for the CNC controller.

Optimal utilization of molds

Connected Mold-ID from Balluff provides condition-based maintenance of your tools without cumbersome and error-prone tool logs. Because Mold-ID stores all the relevant data, such as drawing number, number of shots, last main-tenance or lifetime, automatically on the injection molding tool. You can call up and review this data at any time. Inability to plan and absence of availability resulting from manual tool handling are a thing of the past. Mold-ID lets you make optimal use of your injection molding tools.

The best part: Mold-ID from Balluff lets all machines be upgraded individually, without the manufacturer and regardless of the location. This is because Mold-ID is an autonomous system.