- Sensor and networking excellence for Packaging, Food, Beverage, Pharma, and Personal Care industries

- Life Science

- Steel and Metallurgical Industry

- Drive Technology

- Efficient metalworking using sensor and automation technology

- Mobile Equipment

- Energy Production

- Advancing battery manufacturing automation: Achieving superior efficiency and quality

- Automobile industry and suppliers

- Plastic Industry

- Intralogistics automation: improve efficiency and throughput

- White goods

- Electronics industry

- Tire Industry

- Traffic Engineering

- Robotic sensing: Precision and efficiency in robotics automation

- Automation in the semiconductor industry

- Components for hydraulics and pneumatics

- Achieving compliance and quality in automated pharmaceutical manufacturing

- Personal care and cosmetic manufacturing: elevate OEE with specialized components for packaging automation

- Elevate food safety and OEE through advanced automation technology

- Streamline beverage automation: achieve OEE excellence in bottling and manufacturing

- Elevating packaging automation: Achieve unmatched OEE and flexibility

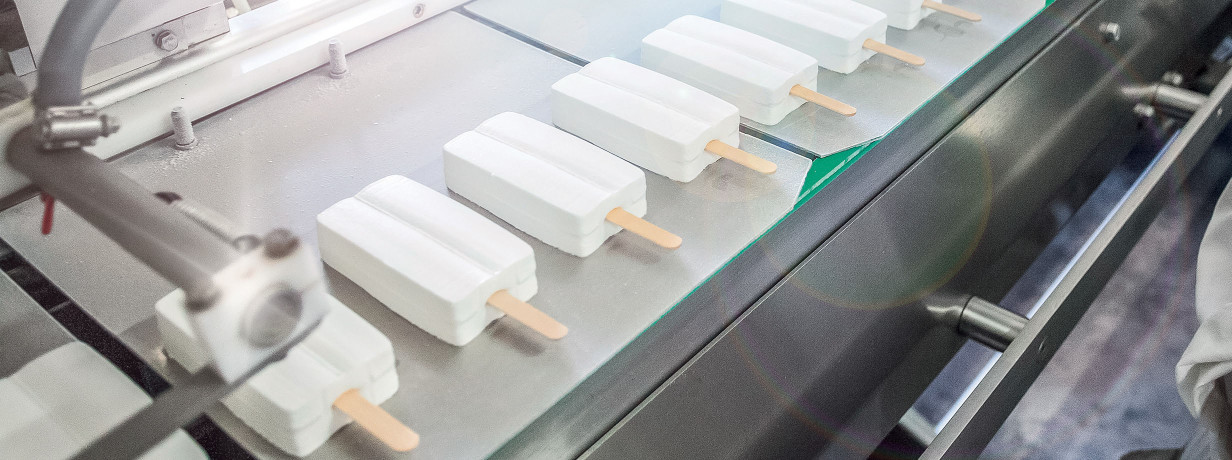

Elevate food safety and OEE through advanced automation technology

Driving safety, efficiency, and sustainability in food manufacturing through specialized automation solutions

In the face of challenges such as shifting consumer tastes, stringent food safety regulations, and growing sustainability imperatives, the food and beverage industry is increasingly turning to advanced automation. Leveraging Balluff's tailored sensors, robust networking systems, and versatile automation components, we enhance your food production equipment and processes. This boosts Overall Equipment Effectiveness (OEE), ensures compliance with safety standards, and aligns with your specific operational and sustainability goals.

Explore how to streamline a tubular bag filling line

See our components in action, explore functionalities, and understand how our solutions fit your unique food production and process automation needs.

1

About this application

1

In this tubular bag filling line application, Balluff’s sensor technology, code reading, and condition monitoring solutions are crucial for increasing OEE and ensuring compliance with food production safety standards.

2

Endless tube with optical sensors

2

Triggered reading of a barcode or 2D code. In the sensor BVS ID the code is verified according to a predefined reference. Any failure is reported to the system. In parallel the BVS ID sensor is collecting Condition Monitoring data for the machine environment. These information or resulting errors are sent automatically to the IT system via MQTT or can be retrieved with the REST API protocol.

3

Verification of product sample

3

After the filling and sealing process of the tubes the pack is verified for the right code consistency and the results plus image can be saved for traceability reasons in the factory’s IT system.

4

Verification of packaging process

4

For commissioning multiple filled units are grouped and special numbers of packs are collected and repackaged. This package is verified by the 2D code and the correlated information for this code is saved in the factory’s IT system for traceability reasons.

5

Monitoring of control process

5

Monitors attached to the machine display the analysed images and result values in monitor mode. Additionally there is a statistical information of the production process. The user can parallelly switch to failed tests to recall the image and the result parameters.

6

Condition Monitoring Panel

6

Remote accessibility to the Sensors for product data and condition monitoring parameters like temperature, vibrations or operating times on multiple positions of the machine enables the optimization of machine processes or predictive actions to reduce production slow down. These data are automatically sent by MQTT to a centralized data broker or can be retrieved by REST API protocol from the sensors. These data give a “health” overview of the complete machine.

Discover applications: automation components for your unique food manufacturing processes

Gain a competitive edge in food production with Balluff's specialized automation solutions, designed to optimize your OEE while addressing unique industry challenges.

Position detection in hygienic areas

Our range of photoelectric stainless-steel sensors are perfect for hygienic areas like sausage production, where they ensure the correct positioning of meat pieces on conveyor systems.

Advantages for machine builders & food manufacturers

We provide specialized solutions for both machine builders and food manufacturers, with top-tier components promoting safety, green manufacturing, timely maintenance, and more.

For machine builders:

Components aligned to specific equipment and machine needs

Integrated compatibility with existing systems

Boosted machinery efficiency and dependability

Improved inter-machine communication technology

For food manufacturers:

Boosted production output and OEE

Elevated food quality and uniformity

Minimized operational downtime and servicing

Promoted sustainable and responsible manufacturing

Key application areas in food manufacturing: enhancing excellence through OEE insights

Discover the seven critical areas where our advanced automation components take center stage in food production. Each application area offers unique advantages, aligned with OEE principles.

Download the OEE expert book to explore these applications in-depth

Ensuring hygiene in meat processing

In the meat processing industry, meeting stringent hygiene and product quality standards is non-negotiable. Balluff's sensors and system solutions are specifically designed for hygienic applications, offering unmatched reliability and flexibility even in the most challenging conditions.

Dairy production: quality and traceability

The dairy industry requires not just strict hygiene but also real-time, transparent production processes. Balluff's comprehensive range of sensors and system solutions enables modular production lines, providing the traceability and flexibility essential for efficient dairy production.

Essential products for redefining each phase of food manufacturing

Unlock new levels of efficiency and safety with Balluff's specialized products. From predictive maintenance to robust networking, our solutions are designed to elevate your OEE in food manufacturing and automation.

Condition monitoring

Detect early signs of wear with our predictive maintenance tools.

Connect and discover more

Contact us today or browse additional resources below to take the next step in your food production journey.

Downloads

-

Revolutionizing OEE in packaging food & beverage

-

Industry brochure filling and packaging Industry

-

Products for packaging, food and beverage for food safety