- Sensor and networking excellence for Packaging, Food, Beverage, Pharma, and Personal Care industries

- Life Science

- Automation in the semiconductor industry

- Steel and Metallurgical Industry

- Drive Technology

- Metalworking

- Mobile Equipment

- Fluid Power Technology

- Energy Production

- Advancing battery manufacturing automation: achieving superior efficiency and quality

- Automobile industry and suppliers

- Plastic Industry

- Intralogistics automation: improve efficiency and throughput

- White goods

- Electronics industry

- Tire Industry

- Traffic Engineering

- Achieving compliance and quality in automated pharmaceutical manufacturing

- Personal care and cosmetic manufacturing: elevate OEE with specialized components for packaging automation

- Elevate food safety and OEE through advanced automation technology

- Streamline beverage automation: achieve OEE excellence in bottling and manufacturing

- Elevating packaging automation: Achieve unmatched OEE and flexibility

Streamline beverage automation: achieve OEE excellence in bottling and manufacturing

Revolutionizing product quality, efficiency, and sustainability through beverage automation components designed for industry efficiency in bottling plants

Navigating the complexities of fluctuating market demands, rigorous industry standards, and sustainability goals is no small feat in the food and beverage industry. That's where Balluff comes in. Specializing in automation, we provide you with a comprehensive portfolio of advanced sensors, networking solutions, and other technology components.

Our solutions are tailored for plant automation and beverage filling processes, aiming to elevate your overall equipment effectiveness (OEE) and sustainability initiatives. Whether you're a machine builder or a beverage producer, Balluff provides the customized solutions you need to meet and exceed industry challenges.

Explore our bottling filling machine in 3D

Immerse yourself in our interactive 3D visualization of a bottling filling machine. See our components in action, explore functionalities, and understand how our technologies fit your unique beverage automation needs.

1

About this application

1

In this bottling filling line application, Balluff’s sensor, networking, and tracking solutions significantly enhance performance, boosting OEE and adhering to beverage automation industry standards.

2

I/O Modules

2

I/O blocks from Balluff connect binary and analog sensors and actuators to the control level via a bus. By using our modules you can significantly reduce the number of cables required. The Balluff I/O modules also offer additional functions for signal pre-processing and expanded diagnostic options. Various form factors and connection technologies provide solutions for the widest range of requirements, even in extreme environments.

3

Level sensor

3

Level detection in tank with probe BTL-SF:

The strict regulations in the food industry are no problem for our BTL-SF level probe. In applications where hygienic design is essential, it has proven itself many times, because it meets the highest international hygienic standards. This enables you to sell your machinery worldwide. The level probe measures precisely in the micrometer range and enables high filling accuracy.

The special features:

Internationally certified quality (Ecolab, 3A Sanitary Standard, FDA)

Assured hygienic standards and long life thanks to 100 % stainless steel

Can be installed without adjustment

Flexible installation due to standardized interfaces

Neutral to all liquid media, robust against foam

CIP (Clean-in-Place): easy to clean even when installed

SIP (Sterilization-in-Place): suitable for process temperatures up to 130 °C

Rising and falling signal available

4

RFID Solution

4

Recognition of interchangeable parts for bottle transport with RFID solutions BIS01E4 and BIS00WH including Smart Features:

Once the correct format has been set, our RFID solutions offer you additional support. The HF-RFID technology (13.56 MHz) enables automatic recognition of interchangeable parts. The various format parts are reliably detected and identified. RFID even offers you protection against plagiarism. Various system combinations of evaluation unit, read/write head, and data carriers are available for the change part detection.

The special features:

Read/write head with integrated evaluation unit with Profinet, Ethernet/IP or USB 2.0 interface

Processor unit for many data, fast transmission time and simultaneous operation of up to four read/write heads

Visualization directly possible via integrated IO-Link-Master-Port on machine lamp

5

Digital Position Indicators

5

With the digital position indicator from Balluff you can handle great product variety quickly and reliably while processing ever shrinking lot sizes. Because our position indicator offers semi-automated format changing with an exceptionally friendly user interface. This straightforward user guiding and accurate setting of the format increases your efficiency. Not only are format changes made faster, the start-up time and machine downtimes are significantly reduced.

6

Networking Modules

6

Balluff has developed a new generation of network modules for perfect linking of sensors and actuators. The system features highly versatile parameter setting and diagnostics possibilities that can be carried out via display, LEDs and an integrated web server.

The status LEDs on the modules are large, bright, and easy to read and interpret. This saves you time in setup, maintenance or troubleshooting.

With an output current of up to 2 A, the Balluff network modules are capable of driving almost any load. Each output also offers overload protection with LED indicator and a memory feature for easy troubleshooting. And the rugged, full-jacket enclosure also withstands high mechanical loads.

For you this means full-time, overall high performance.

7

Inductive Sensors

7

Our standard inductive sensors are ideal for object detection in metal areas. They are short-circuit protected and operate without contact, making them wear-free and very resistant to dirt and contamination. The sensors are available in configurations from 3 mm Ø to 80 × 80 mm square dimensions.

8

Micromote – optical sensor heads

8

The modular system of the Micromote sensors with innovative sensor elements meets your individual requirements: a variety of housing configurations ensure an especially high degree of design freedom; precise photoelectric modules ensure a high process precision with each application.

9

HF Data Carriers (13,56 MHz)

9

BIS M uses high frequency (HF) 13.56 MHz and supports the standard according to DIN ISO 15693 and/or DIN ISO 14443.

The wide variety of passive data carriers with various dimensions, configurations, memory sizes, operating temperatures, materials, antenna technology, mounting options and ranges allows you to tackle nearly any technical task. BIS M is the most robust system with absolute data security.

10

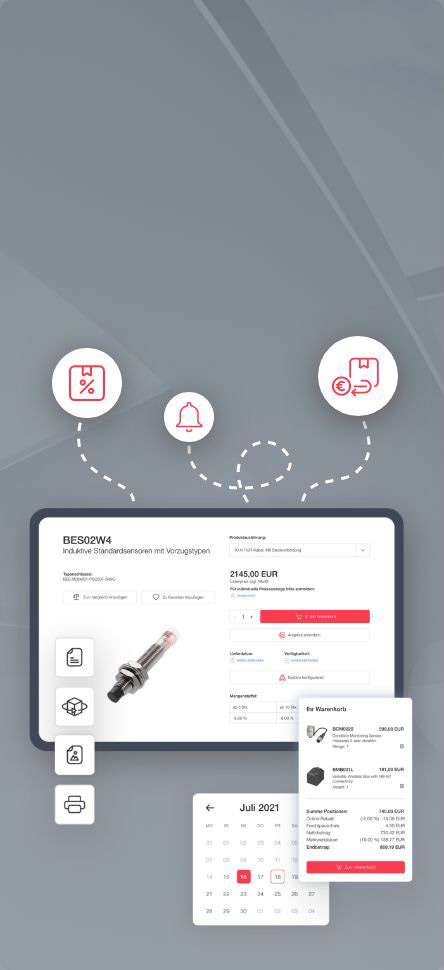

Balluff Engineering Tool

10

When it's manufacturer-neutral startup and configuration of IO-Link devices you need, the Balluff Engineering Tool (BET) is the answer.

This software provides you quickly and easily with an overview of your topologies and allows you to track the status of all the connected IO-Link devices.

You can also parameterize and place the devices in service while also managing the parameters for individual devices or entire topologies.

11

Safety I/O Modules

11

Safety I/O modules: Profisafe over IOLink with BNI0098:

The safe I/O modules combine safety and automation via IO-Link technology. This provides both sensor and actuator signals and can also be used for safety applications. The core of Safety over IO-Link is the Safety Hub with Profisafe for Profinet. Safety switches, sensors, optoelectronic protective devices or safe control devices can be quickly integrated. M12 standard cables are sufficient to connect almost any safe field device.

12

Industrial Cameras

12

Quality control (e.g. label inspection, cap inspection or part detection) with Industrial Cameras BVS0039:

Industrial Cameras provide sharp images and fast data processing for your quality assurance. Used for traceability, our Industrial Cameras BVS CA recognize and check object codes or object texts, in order to meet the required verification obligation.

Thanks to the clearly structured BVS-Cockpit user interface, our industrial cameras can be set up intuitively by anyone and are easy to operate. Without any prior knowledge.

The special features:

Standardized data interfaces (GigE-Vision and USB3-Vision) as well as standardized programming interface GenICam

Integrated memory and FPGA unit for flexible adaptation of integrated functions

Fast data processing

IP67 protection class (for GigEVision version)

13

Photoelectric Proximity Switch

13

Bottle inspection with BOS0285 photoelectric proximity switch with background suppression including Smart Features:

Diffuse sensors with background suppression detect objects within a set switching distance without being affected by the reflective background. And this is almost independent of the colour and surface of the object. Since the transmitter and receiver are housed in one housing to save space, our photoelectric proximity switches are easy to install and quick to align.

The special features:

Reliable object detection with different ranges, independent of surface, colour and material

Detects objects in front of a very close background - even if they are very dark in front of a bright background

Almost constant scanning range even with different degrees of reflectance

Only one electrical device without reflector or separate receiver

With red light or laser red light for the detection of small parts

14

Smartlight

14

Status display of the complete application with SmartLight BNI0082 including Smart Features:

With our signal and display devices, you always know the status of the production. They reliably monitor the status of machines and systems and visualize the output signals of the sensors.

15

Condition Monitoring

15

The Balluff condition monitoring sensor detects various physical variables such as vibration, temperature, relative humidity and barometric pressure, processes them and provides the desired data to a host system via IO-Link. The standardized IO-Link protocol means you can easily parameterize the sensors and match the processing in the sensor to your specific application.

The process data structure allows up to five measured or pre-processed data to be freely configured and cyclically transmitted.

Our condition monitoring sensors thus make an essential contribution to efficient and faultless operation of any equipment and significantly increases the efficiency of the overall system.

16

Retro-reflective Sensors

16

Crate inspection with BOS0286 retro-reflective sensors including Smart Features:

Reliable object detection independent of surface, color and material. With the polarizing filter, even the detection of shiny crates is no problem. Transmitter and receiver are housed in one case, so you can easily mount this photoelectric sensor and align it easily due to generous mounting tolerances.

The special features:

Easy alignment due to generous mounting tolerances

Large reflectors for long ranges

Reliable detection - independent of surface, color and material

With polarizing filter also suitable for detection of shiny objects

Mounting of only one electrical device plus reflector

Discover top applications: components for your unique automation processes

Uncover from Balluff perfectly suited for your specific bottling and beverage production processes, optimizing OEE while meeting your distinct challenges.

Balluff's unique components: Competitive edge for machine builders & beverage producers

Our offerings cater to both machine builders and beverage producers, providing best-in-class components for quality assurance, sustainable production, predictive maintenance, and more.

For machine builders:

Customized components tailored to specific machine requirements

Seamless integration with existing systems and system architecture

Enhanced machine performance and reliability

Improved machine-to-machine communication

For beverage producers:

Increased production efficiency and OEE

Improved product quality and consistency

Minimized downtime and maintenance costs

Eco-friendly, sustainable operations

Key application areas in beverage production: Enhancing excellence with OEE insights

Discover the seven critical areas where our advanced components take center stage in your machinery. Each application area offers unique advantages, aligned with the principles of Overall Equipment Effectiveness (OEE).

Download the OEE expert book to explore these applications in-depth

Your key products for enhancing every stage of beverage manufacturing

Experience unparalleled performance and system reliability with Balluff's suite of automation components. Designed to meet the specific demands of your production, our products aim to optimize your OEE and reduce costs.

Connect & explore further: Your pathway to excellence

Contact us today or explore additional resources below to take the next step in your beverage manufacturing journey.

Downloads

-

Revolutionizing OEE in packaging food & beverage

-

Industry brochure filling and packaging Industry

-

Products for packaging, food and beverage for food safety

Products

Products