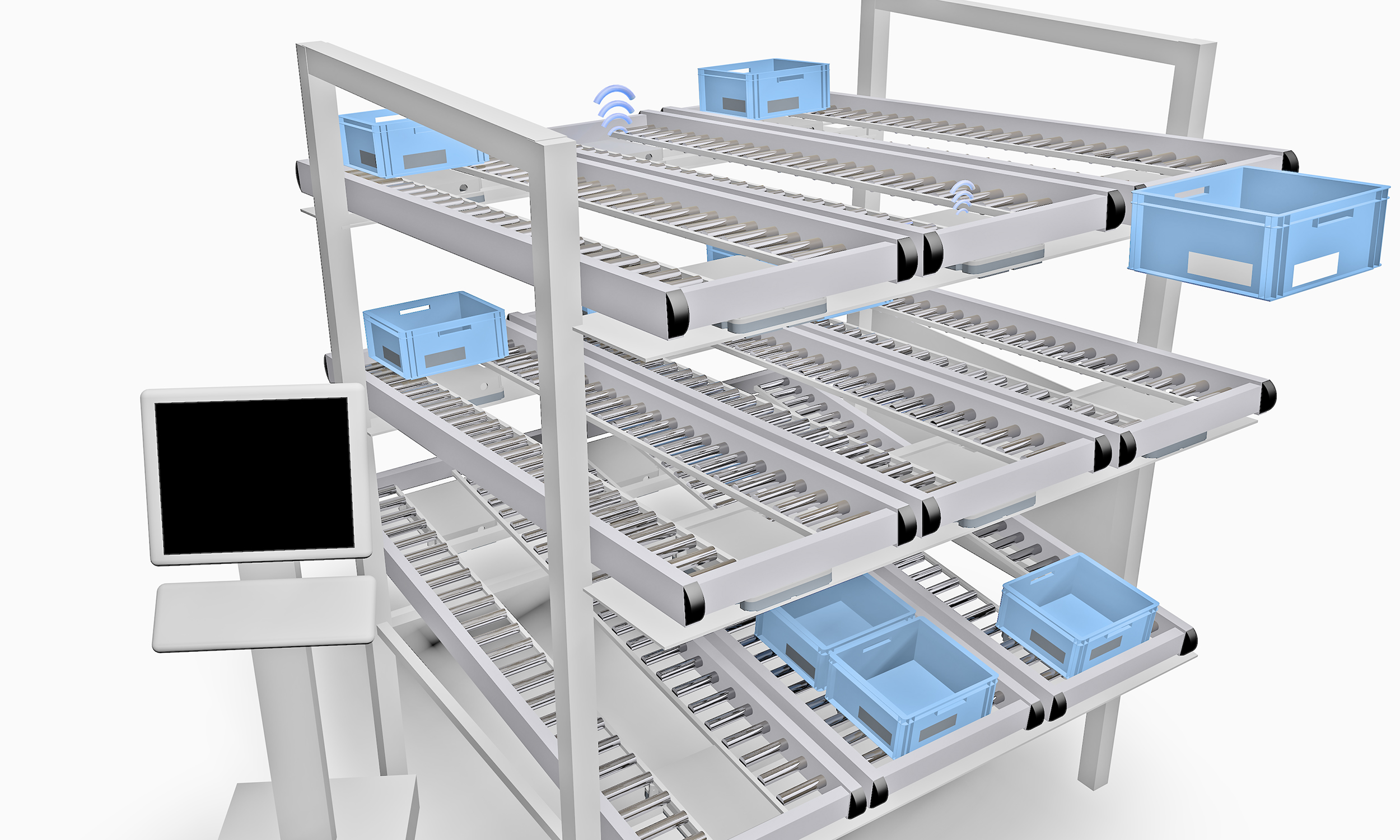

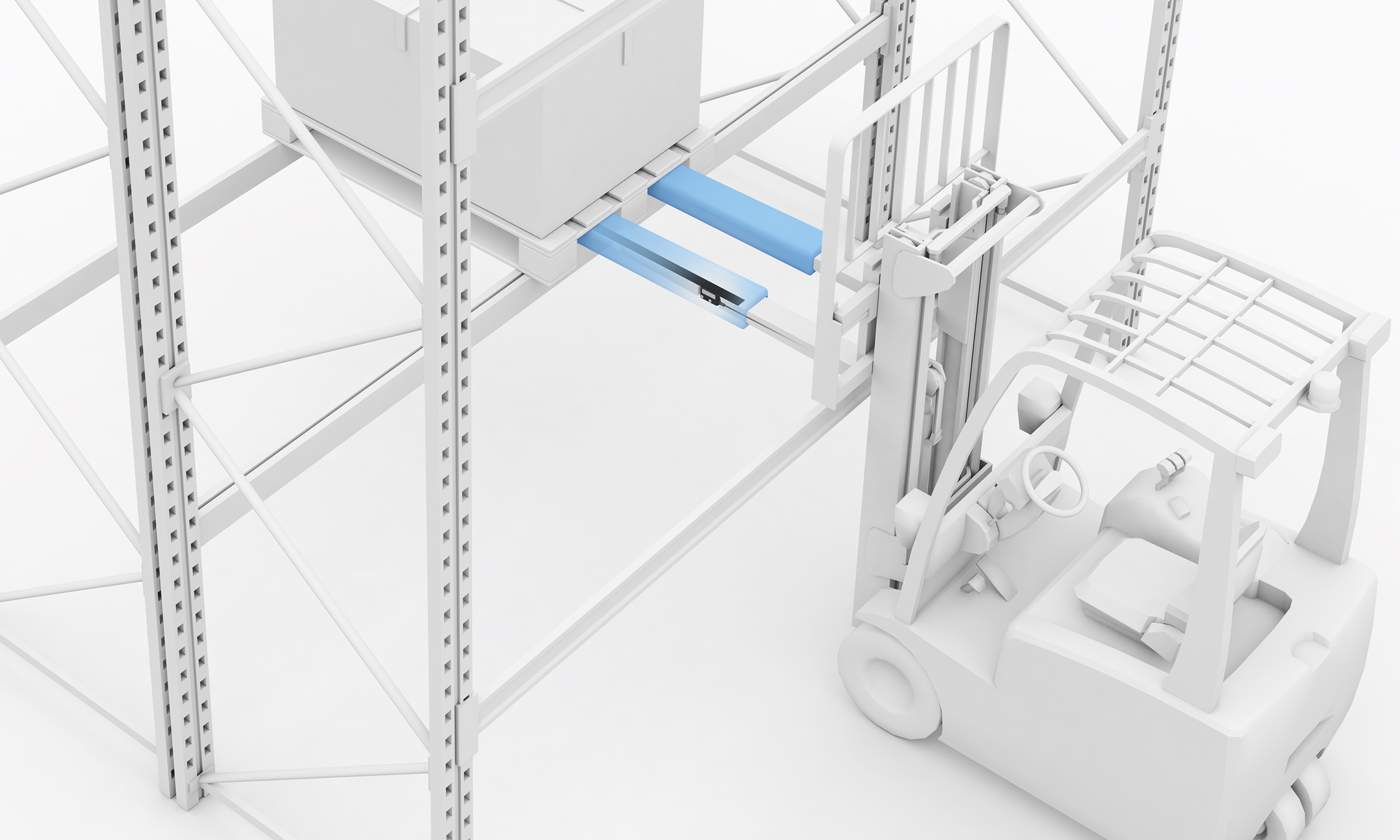

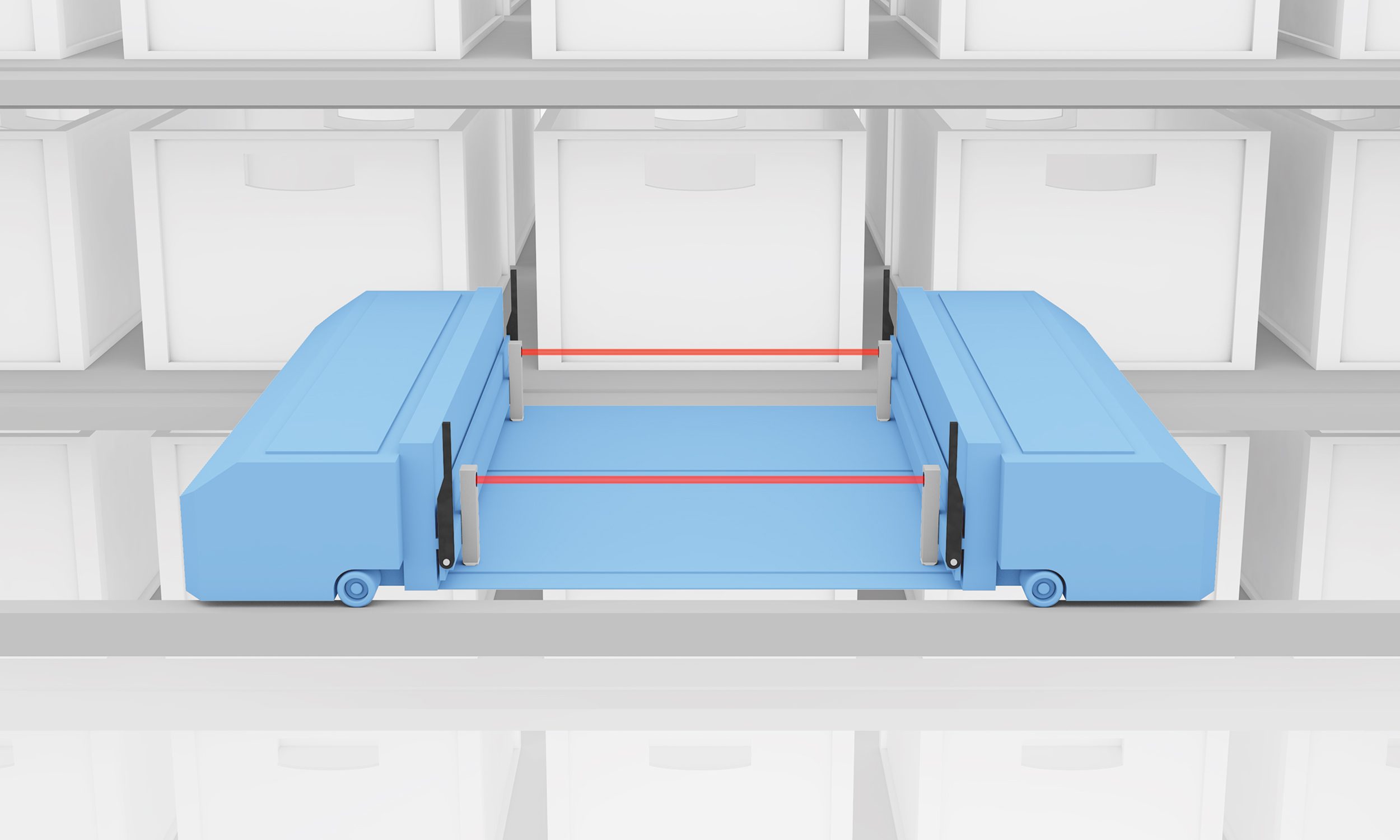

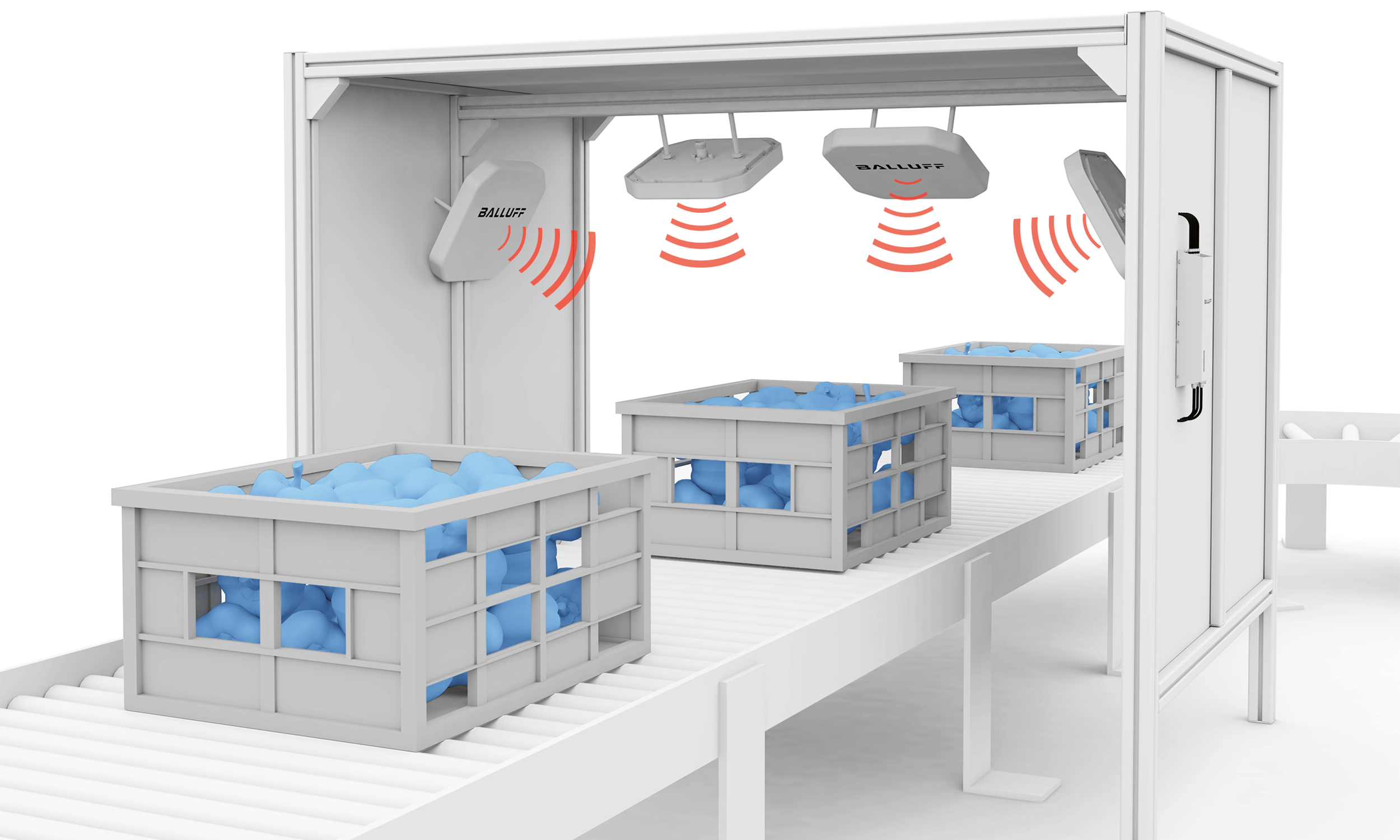

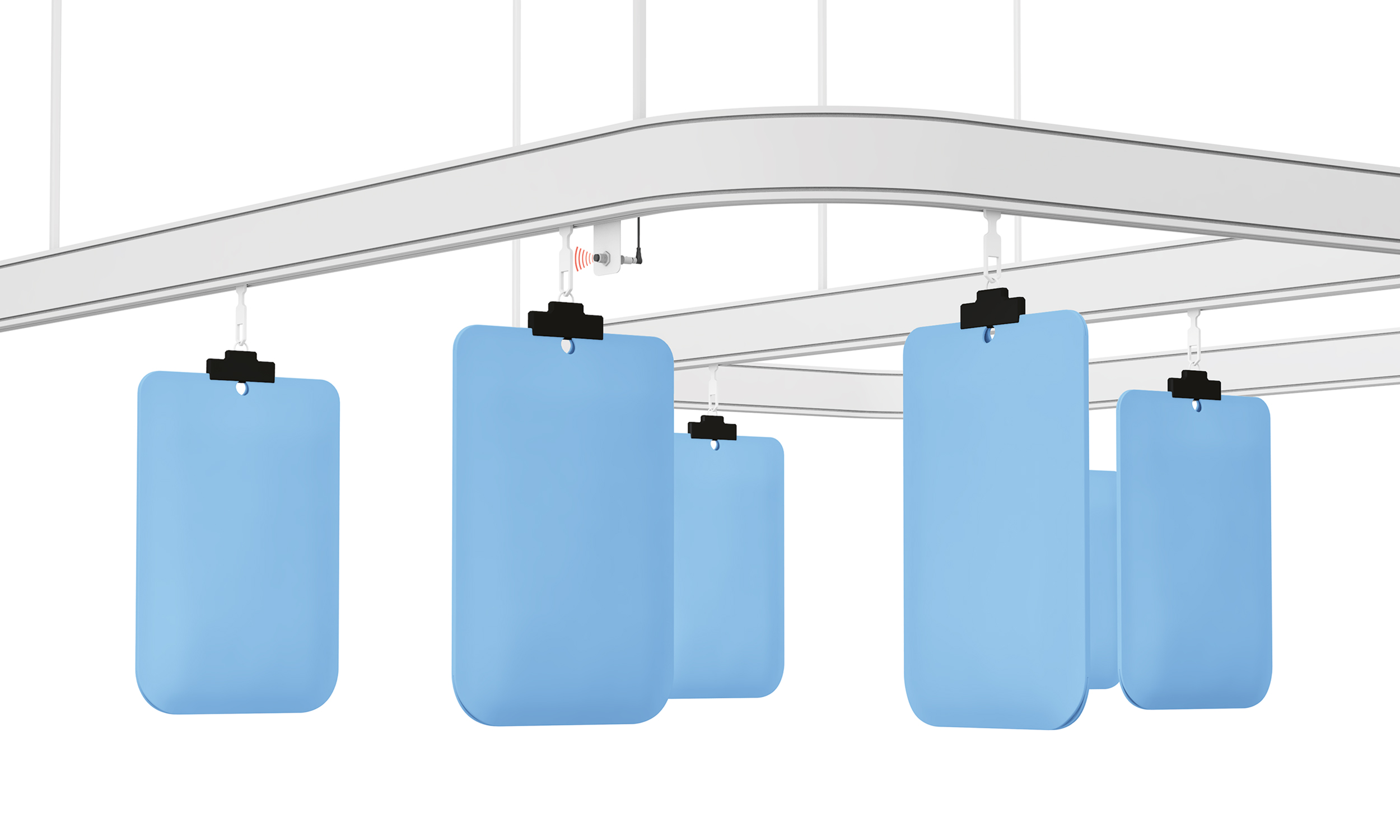

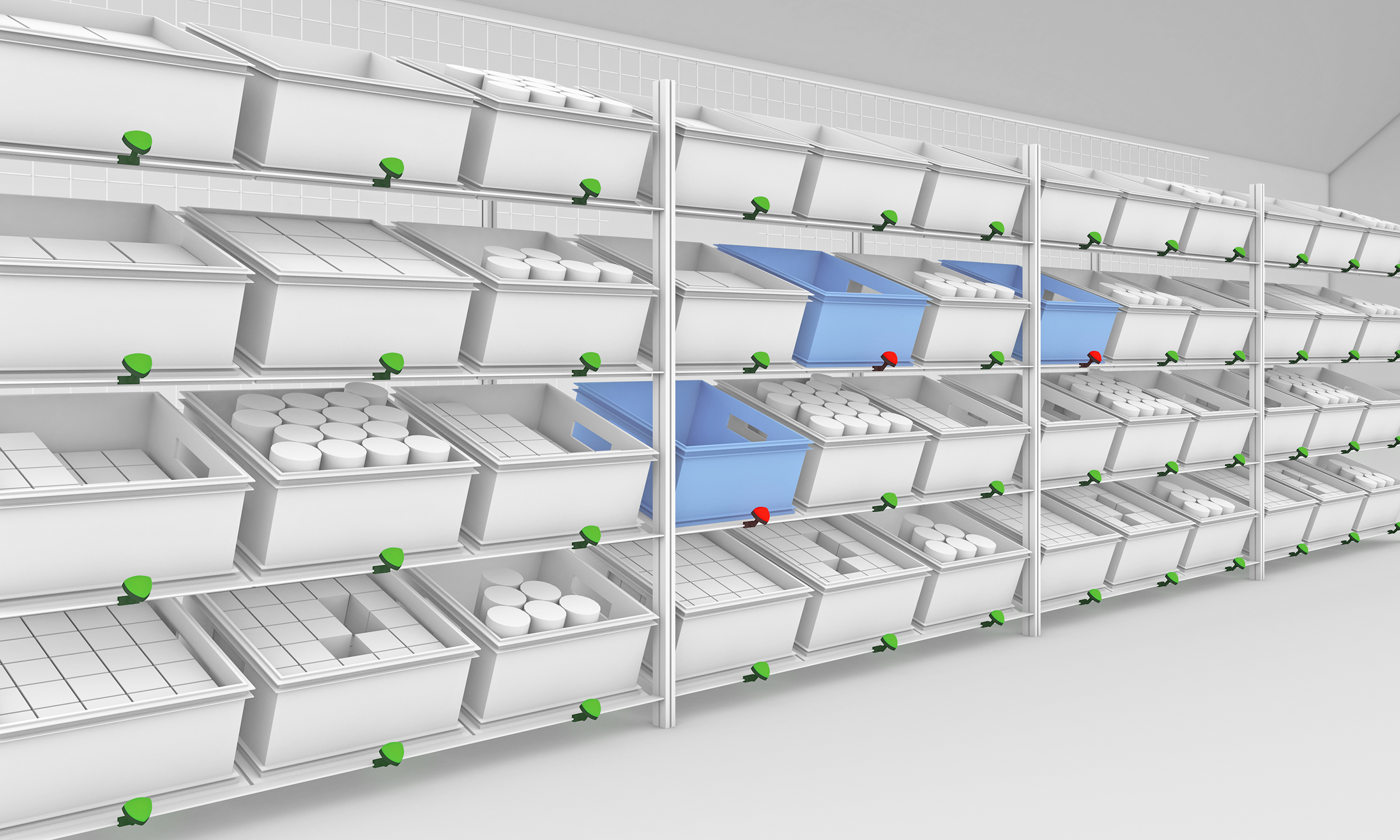

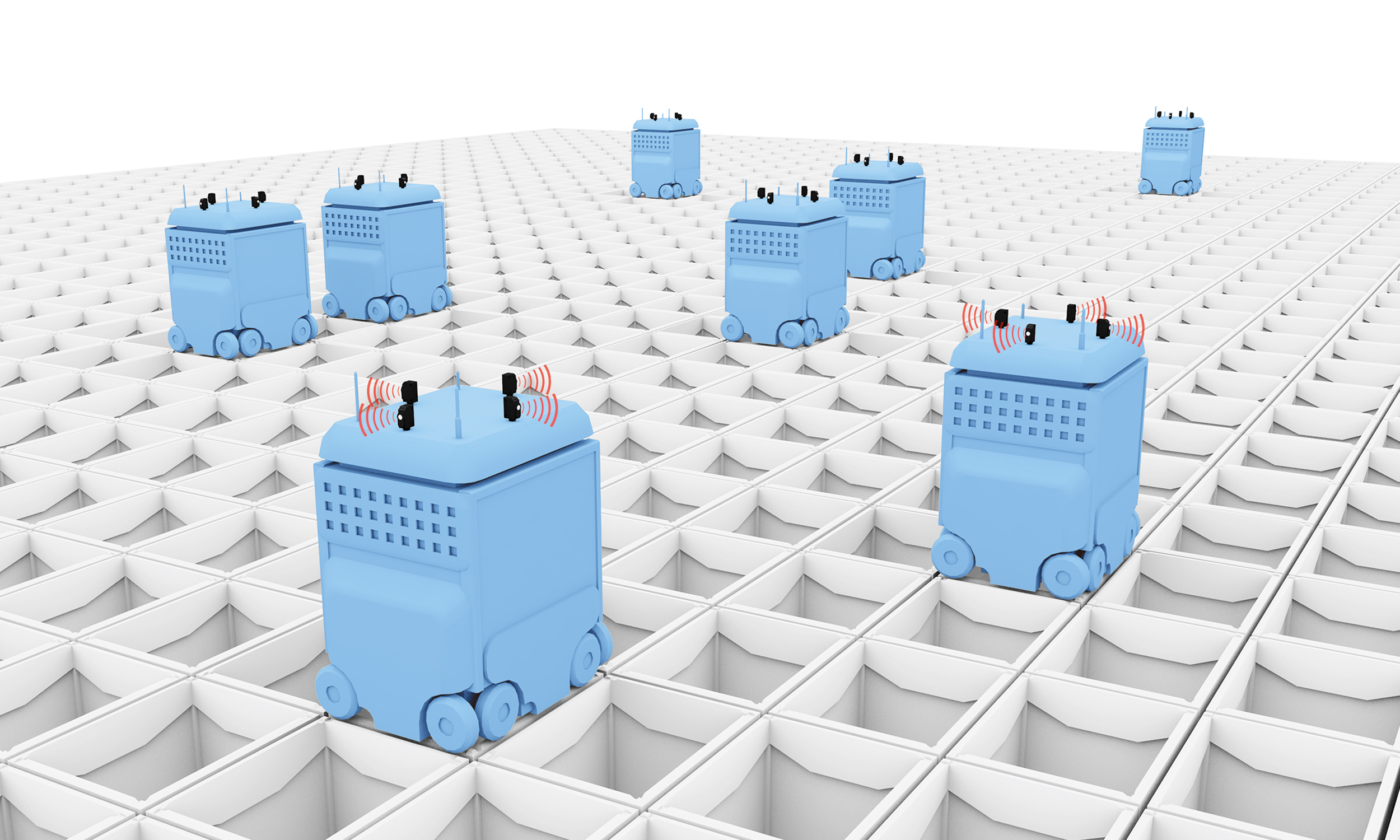

Application examples and solutions

The right solution for every application

Balluff offers you solutions that are optimally matched to your industry, application conditions and requirements. Our application database will help you find the right solution for your application quickly and easily. Simply use the extensive filter function.