- Matrix Vision solutions now all under the Balluff brand

- Comprehensive components and solutions for automated welding

- IO-Link: Intelligent solutions for modern automation

- Smart Automation and Monitoring System

- Condition Monitoring

- Tough Performers

- Miniaturization

- Quality Assurance

- Explosion Protection

- MicroSPOT

- Architects of Smart Manufacturing

- Level Detection

Smart Communication

IO-Link – the foundation for the intelligent manufacturing

Intelligently combining industrial networks with the bi-directional IO-Link communication standard is the ideal solution for ever faster, more flexible, more efficient, and more adaptable production.

IO-Link not only integrates all the sensors in the fieldbus level, but also enables lean wiring and equipment concepts, in which even analog signals can be transmitted noise-free by digitizing them. We offer you a high-performance infrastructure for reliably managing your growing volume of data. This transports your data through the entire manufacturing process and is the first step for enabling seamless communication from the sensor into the internet.

These are the best prerequisites for IO-Link to distinguish itself as the enabler for the IIoT because smart communication is indispensable for the factory of the future.

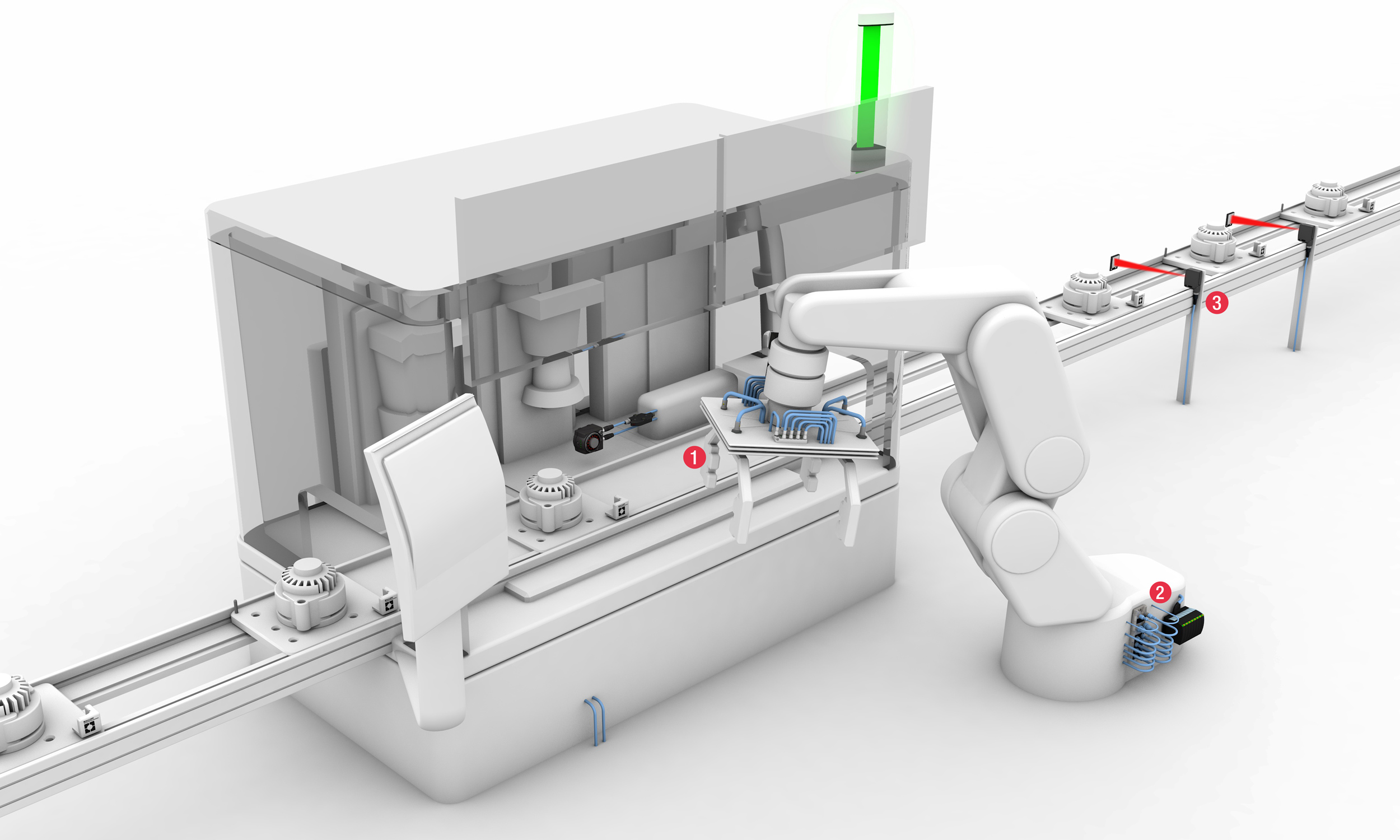

Application example

(1) Monitor sensors centrally and optimally position them as the process requires

(1) Monitor sensors centrally and optimally position them as the process requires

With IO-Link you can position sensors in the machine just as the process requires, since accessibility of the sensors is no longer a factor. Process monitoring, configuration and error analysis of the IO-Link devices now takes place in the controller. This optimizes the timing of machine processes. Signal delays and distortions are also reliably eliminated thanks to the digital transmission of data, which also ensures high signal quality.

(2) Compress data and save IP addresses

With IO-Link you need only one node/IP address to transmit the data of up to 496 inputs/outputs. By compressing the data, you preserve valuable addresses and minimize critical installations. Here the IO-Link actuator/sensor hub with its expansion port sets the standard. In combination with the IO-Link master, you have completely new options for the decentralized expansion of your network topology. You can use this port to connect valve interfaces or an additional IO-Link hub: And you can do so simply, using plug-and-play. Additional in- and outputs are processed just as easily – with no additional master.

(3) Fast sensor replacement and prompt commissioning

IO-Link enables quick, error-free sensor replacement and prompt commissioning. You can significantly reduce downtime since the parameters of a replaced IO-Link sensor are automatically written from the IO-Link master or controller to the new sensor. Commissioning processes, format changes or recipe changes are handled centrally via the controller's function modules. This saves time and minimizes the potential for mistakes. Another advantage to you: IO-Link devices cannot be mixed up, since they are automatically identifiable via IO-Link.