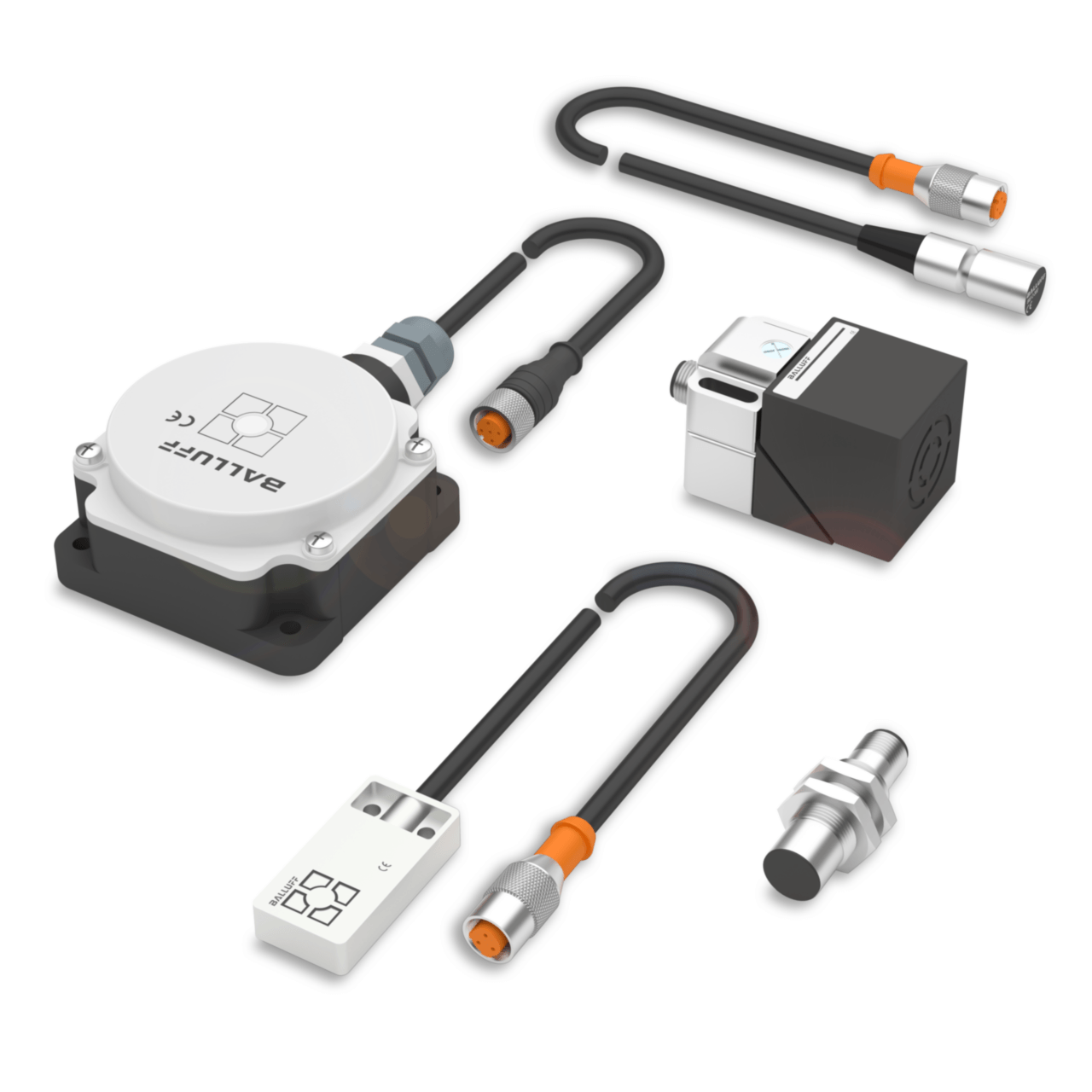

LF RFID system (BIS C)

Reliable information stream for manufacturing

Especially high-performing and flexible are the BIS C low-frequency RFID systems with the reliable tool identification in coolant- and lubricant-enriched machining centers. An exact positioning is not always necessary. Many data carriers can also be dynamically read and described "in passing".

LF (70/455 kHz) is the first choice for the tool identification over short ranges. Other areas of use are tool transport with conveyor systems, FTS and pallet transport systems and the assembly technology and organization of supplies.

Key benefits

- Great diversity of variants of data carriers and read/write heads for very diverse applications and difficult conditions of use

- Wear-free, maintenance-free and insensitive to dirt

- High interference resistance and secure data transfer via special testing software in the processor units available to all globally standard bus systems

- Memory capacity up to 8 kbytes

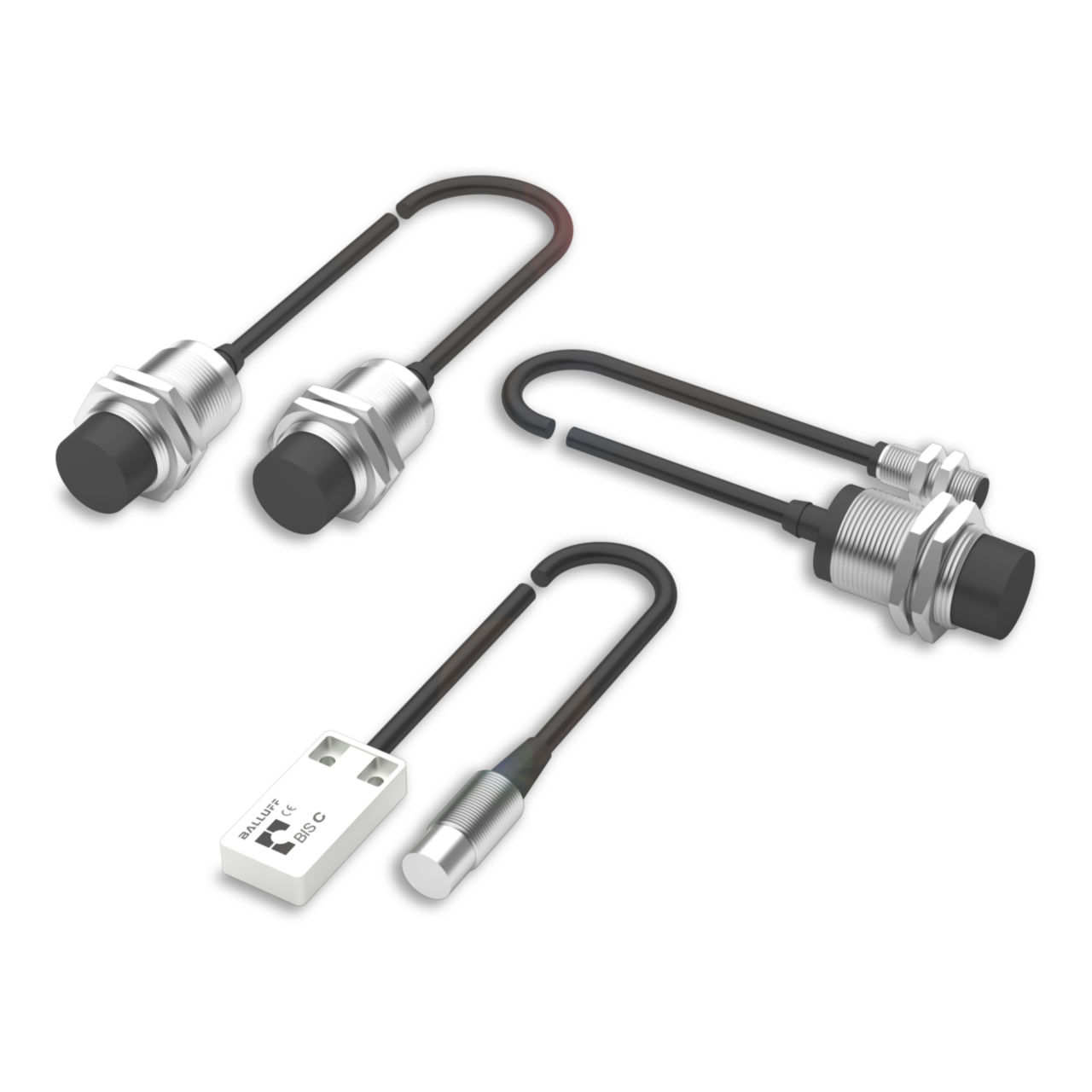

LF RFID tags (70/455 kHz)

- Variety of special LF tags for almost all areas of industry

- Robust, industrial, weather and temperature-resistant RFID tags

- EEPROM tags with 511, 1023, 2047 byte memory capacity

- FRAM tags with 8 kByte for almost unlimited read/write cycles

- Mounting options: Glue or screws

- 10 mm BIS C-122 tool ID tags: This classic, used millions of times, is a global standard

- Corner tags with double coils don't require rotations in pallet identification

- Code tag customization according to customer requirements

LF RFID data coupler (70/455 kHz)

- Data couplers work like an extension cable

- Maintenance-free transmission without mechanical wear

- Fast and secure signal transmission

- Various cable lengths: 1 m, 2 m and 5 m

- Easy wiring of rotary index tables, interchangeable punch heads, etc.

- Increased function queries, even in previously inaccessible places

LF RFID processors (70/455 kHz)

- Excellent EMC thanks to the robust zinc die-cast housing

- All connections easily accessible from the front

- Variable mounting configuration for easy installation on top-hat rails or profiles

- LCD display and push buttons for easy commissioning

- Each reader signals its operating status via two LEDs directly on the processor unit

- Integrated IO-Link master port for connecting IO-Link-capable sensors and actuators

- Web server for convenient remote status monitoring

- Function modules from many common control system manufacturers make for quick integration

- Integrated 2-port Ethernet switch for line and ring topology

- Small and compact (172 × 48 × 62 mm)

- USB interface for fast commissioning without bus connection

- BIS Cockpit: Reader can be parameterized independently of the interface using a PC-based software tool

- Power supply via robust 7/8” plug for harsh industrial environments