- Sensor and networking excellence for Packaging, Food, Beverage, Pharma, and Personal Care industries

- Automobile industry and suppliers

- Drive Technology

- Steel and Metallurgical Industry

- Life Science

- Mobile Equipment

- Efficient metalworking using sensor and automation technology

- Energy Production

- Plastic Industry

- Advancing battery manufacturing automation: Achieving superior efficiency and quality

- White goods

- Electronics industry

- Tire Industry

- Traffic Engineering

- Intralogistics automation: improve efficiency and throughput

- Robotic sensing: Precision and efficiency in robotics automation

- Automation in the semiconductor industry

- Components for hydraulics and pneumatics

White goods

Produce household appliances reliably and efficiently

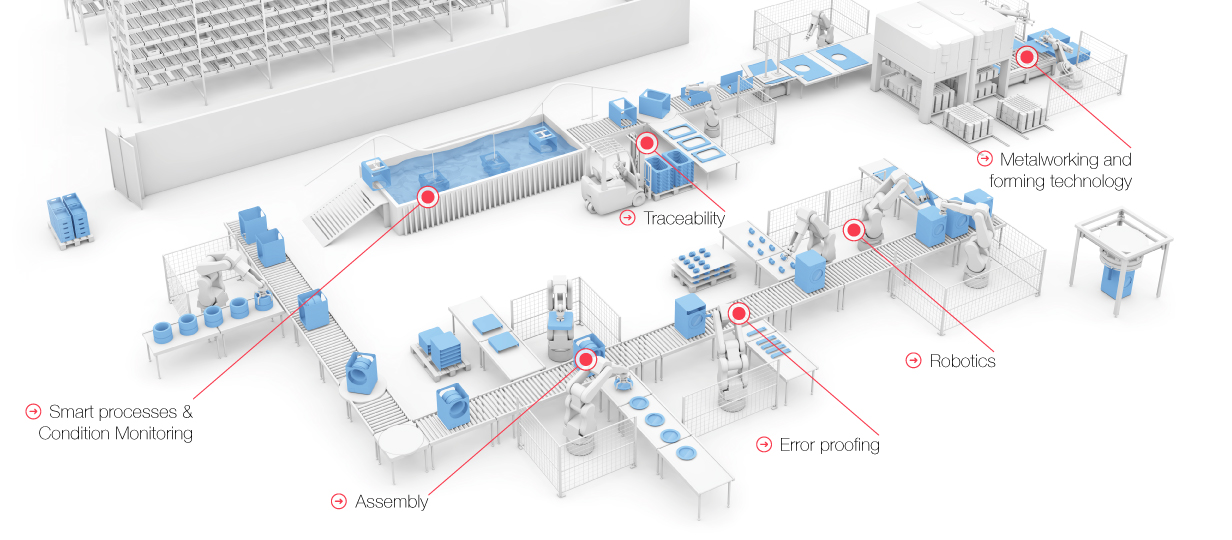

From metalworking to intralogistics to assembly: Balluff supports you with a wide range of solutions for the error-free and efficient production of white goods.

Some of the important topics in this area, e.g. traceability through RFID or handling and assembly technology, have been on our minds every day for decades. But we also deal intensively with newer production requirements such as condition monitoring and IIoT and can offer you innovative solutions to optimize your manufacturing process.

Metalworking and forming technology: Benchmarks for the standards of tomorrow

Mechanical presses have become an indispensable part of metal forming. The particularly high-quality and precise tools and molds used are usually designed for high volumes. Literally no one can afford long downtime here, because every production delay costs you time and money – especially if you also have to replace damaged assets. You can rely on sensor solutions from Balluff: They always record the exact press position during machining operations, detect malfunctions immediately, and avoid consequential damage because the press shuts itself down immediately in an emergency.

Traceability and intralogistics: High speed, high transparency, high quality

Continuously managing inventories and material movements while reliably avoiding errors is a challenge for companies in almost all industries. Automated processes enable you to store and retrieve even large quantities – in less time and with greater precision. So, it‘s no wonder that dynamic shuttle systems and stacker cranes are increasingly replacing manual warehouse work. Another factor for greater efficiency is high process transparency. Traceability of all process steps – from raw material procurement and production to consumption and disposal – is correspondingly important. Balluff offers you reliable solutions for intralogistics as well as highly accurate identification solutions with software-controlled control options.

Assembly, robotics and error proofing: Data in flow, processes in check, production under control

Whether you want to bundle signals, collect and track data from your assembly process, or display operating states: Balluff helps you manage all these tasks in your assembly effortlessly.To meet your high production requirements, you already use a wide range of assembly methods, from manual workstations to highly automated production lines using robotics. In the innovative field of robotics, we also support you in maximizing efficiency and ensuring high product quality – with solutions that, for example, replace complex cabling, enable fast tool changes and facilitate interaction between man and machine.To ensure that no errors occur in the complex processes of your production, we offer products for integration into your error proofing applications. They also enable continuous quality control, which increases overall equipment effectiveness (OEE).

Smart processes and condition monitoring: Flexible, intelligent, trouble-free

With systems for process and condition monitoring consisting of smart components, Balluff contributes to the efficient and trouble-free operation of machines and plants in industry. For example, sensors can prevent unplanned downtime by reliably recording and monitoring fill level, temperature or pressure, providing data on the condition of the plant and, thus, enabling you to carry out preventive maintenance. You recognize changes such as wear or even malfunctions of individual components more quickly and can better coordinate their maintenance. Balluff sensors can automatically monitor defined limit values of production resources and inform you if they are undershot – or directly reorder the resources. This replaces manual checks and increases overall equipment effectiveness (OEE).

Downloads

-

Industry brochure white goods – household appliances