IO-Link – Identification

How IO-Link creates lean identification solutions

If your identification function is non-time critical, involves little data and requires a lean topology, with an IO-Link solution you do not need a separate processor unit in the field. The read/write head is connected to the standardized, neutral IO-Link interface using a simple unshielded 3-conductor sensor cable. The simplest method is to use plug-and-play, so you don’t need a function block.

Application examples

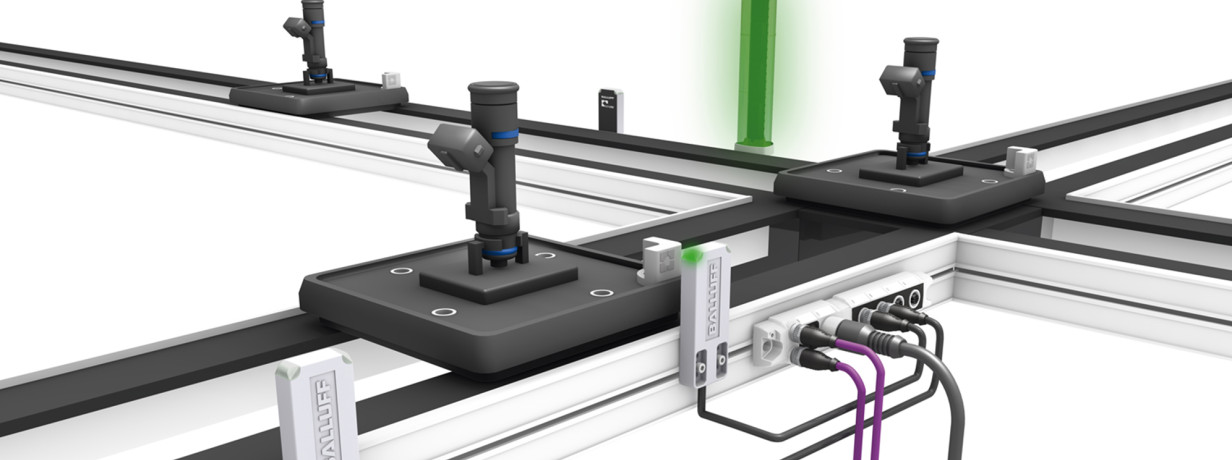

A RFID read/write head reads the corner data carrier which can be read from two sides. Both products are especially designed for mounting on standardized workpiece carrier systems and standardized rail systems. Simply connect the RFID read/write head to the IO-Link master unit, which you can then connect up to four IO-Link devices. Using Profibus, the data is made available to the host controller. If you have little space available, a small read/write head with separate controller unit is ideal.

Components for automated identification with IO-Link

With IO-Link-based automated identification you only need three components:

Data carriers which carry the object data through the system (Available in various form factors)

IO-Link capable read/write heads including controllers, which represent the interface to the data carrier, provide data preparation and make the information available over the IO-Link interface

IO-Link master unit which provides four IO-Link master ports and communicates with the controller over the fieldbus

Products

Products