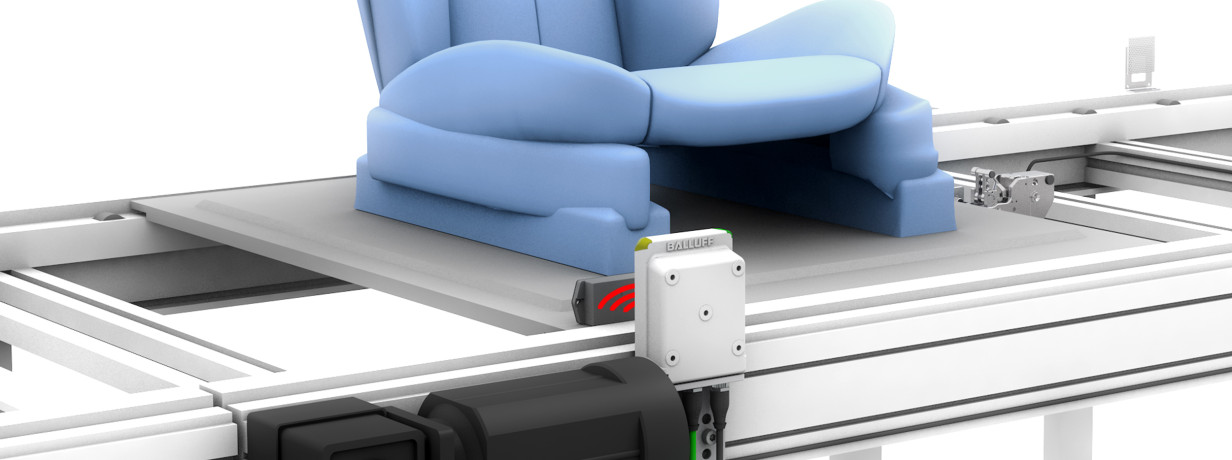

Enable traceability in seat assembly

BIS RFID systems from Balluff are the first choice for making every single work step and every material used in seat assembly traceable. RFID data carriers are attached to the workpiece carrier for this purpose and travel through the entire assembly process with it. The data stored on the data carrier is read by the RFID reader and shows exactly what has happened in each production step. They document the completed steps and also any errors that have occurred, which is why the affected assembly is then sent to the post-processing area.

In this way, the throughput is recorded and documented in real time, which confirms your high product quality. Reading and writing is automatic, so manual steps and potential sources of error can be eliminated. The stand-alone readers are connected directly to the control level via Profinet or Ethernet/IP interface, without requiring an additional evaluation unit.

The features

- Seamless integration into applications through globally available 13.56 MHz technology

- Robust, compact zinc die-cast housing for direct mounting on metal

- All around visible status LEDs reduce commissioning and downtimes

- Simple S7 programming through ready-made function blocks

- Integrated web server for device setup, status monitoring and diagnostics

Downloads

-

Industry brochure automotive