Tool-ID - Optimal tool management through tool identification and management with RFID

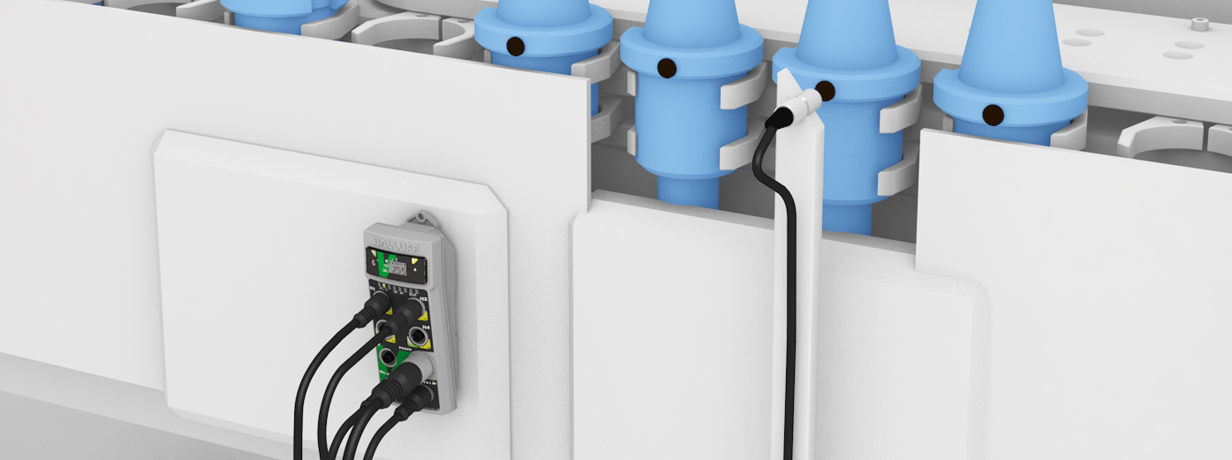

Tool ID BIS C

In machining centers, cutting tools are changed frequently - RFID offers an extremely efficient solution for automated tool identification: Without contact, all tool data such as dimensions or place of use, duration, type and wear are read in automatically, stored on the data carrier in the tool holder and transferred to the system memory. In this way, the tools can be optimally used and managed. The advantage is higher machine availability, reduced inventory and minimal scrap. In addition, the data is available at all times and is neither entered incorrectly nor completely forgotten.

The BIS C low-frequency tool ID solution is suitable for reliable tool identification at short ranges in machining centers with high levels of cooling and lubrication. The low-frequency system has proven itself over many years - especially due to its robustness and reliability in metal environments. This technology therefore remains an ideal choice for tool identification.

- Robust and reliable identification in metallic environments

- Data carrier in standard size for Ø10mm bore in tool holders

- Decentralized data storage directly at the tool