Flexible feeding systems using reliable sensors

Feeding technology specialist IFSYS has relied on sensor solutions from Balluff since day one

Industry sector: Automation technology, feeding technology | Customer: IFSYS Integrated Feeding Systems GmbH

IFSYS develops high-quality feeding systems for the automotive, electronics and pharmaceutical industries. Since the company's founding in 2006, IFSYS has relied on reliable components from Balluff, including fork light barriers with IO-Link technology, proximity switches and industrial cameras. These sensor solutions enable easy integration, flexible customization and support the ongoing development of innovative feeding technology.

The situation

IFSYS specializes in feeding technology and helps its customers to make their production processes more effective. The company has a broad portfolio of feeding systems, from systems that manipulate large screws to those for the smallest pins. IFSYS also offers flexible feeding systems and systems with optical part recognition and artificial intelligence (AI). Innovation is a central component of the company philosophy: IFSYS is continuously improving its processes and is always looking for new, even better solutions.

Balluff has been a reliable partner for us since day one. The sensors can be integrated quickly and offer us the reliability and flexibility we need to continuously improve our feeding systems and adapt them to new requirements.

Sebastian Demar, Managing Director IFSYS

The challenge

In order to meet the high demands of different industries and maintain its own innovative advantage, IFSYS requires extremely reliable and versatile components for its feeding systems. The challenge is to develop systems that are not only efficient and precise, but also flexible enough to adapt to different applications. In addition, the integration of new technologies such as optical recognition and AI requires close collaboration with partners who are also committed to innovation and quality. IFSYS was therefore looking for solutions that would enable easy installation and quick customization to further increase the efficiency of production processes.

The solution

IFSYS has relied on Balluff products since the company was founded. The long-standing partnership between the two companies is characterized by mutual trust and a shared focus on innovative solutions. Balluff supplies IFSYS with reliable components such as proximity switches, photoelectric sensors and industrial cameras, which are crucial for the functionality of the feeding systems.

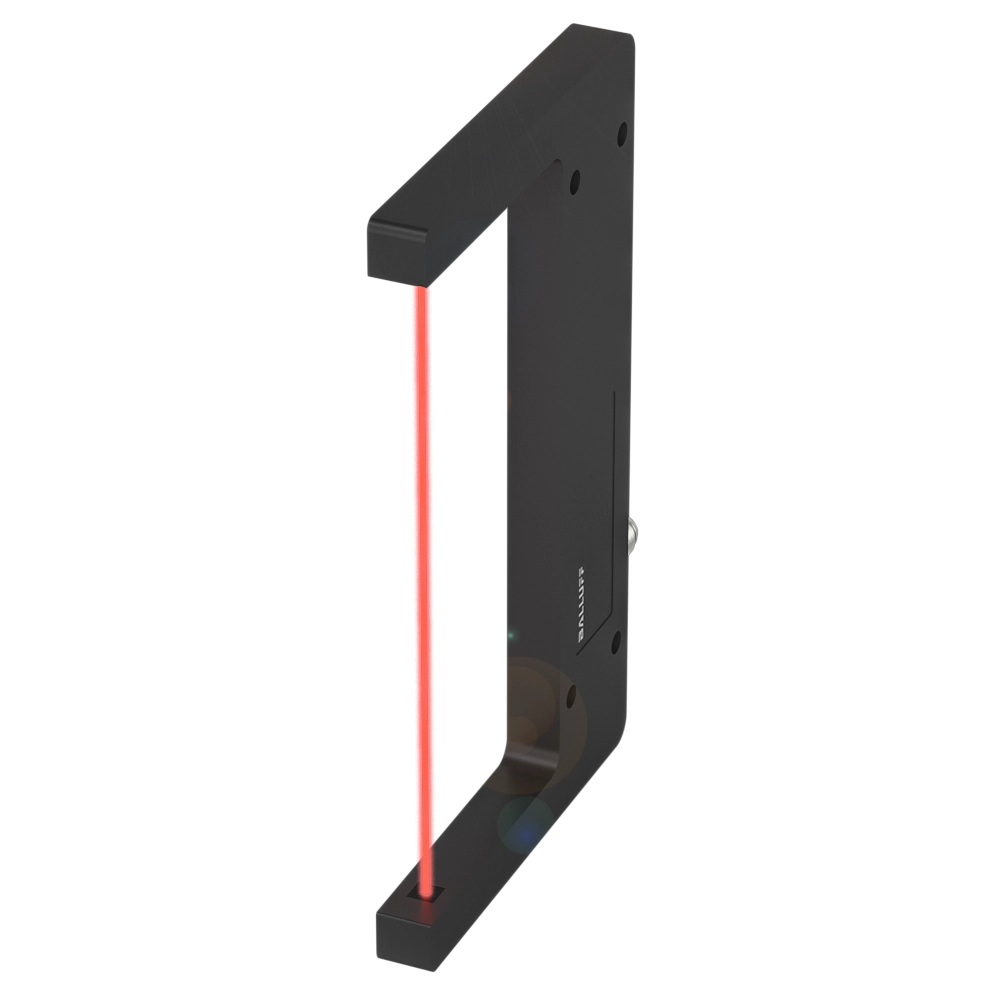

IFSYS particularly values Balluff's fork light barriers. This technology enables even more precise control and monitoring of the feed systems and leads to a further improvement in production processes. The new generation of these fork light barriers is equipped with an IO-Link interface, which significantly expands the application range of the sensors. These sensors are available in various widths from 30 to 120 millimeters and are very easy to install and adjust thanks to integrated and standardized mounting holes.

The result

By using Balluff sensors such as the fork light barriers, IFSYS further increases the performance of its feeding systems to meet the high demands of its customers. These reliable sensors further the smooth, flexible operation of the plant. In addition, standardized interfaces such as IO-Link simplify the integration of new components and significantly accelerate changeovers.

This has enabled IFSYS to increase efficiency in production and remain true to its philosophy of innovation. Thanks to Balluff's proven partnership and prompt service, IFSYS achieves its innovation goals and continues to provide its customers with first-class, future-proof solutions.

The advantages of fork light barriers

- Transmitter and receiver already aligned in one housing

- Operation in SIO mode with switching output and signal monitoring via IO-Link possible

- Device replacement without manual parameter setting and knowledge with data stored in the master

- Mechanically fully backwards compatible

- Integrated pulse stretching

- IP67 zinc die-cast housing for use in harsh environments

Products in use

Standard metal fork light barriers

- Dimension

- 10 x 140 x 84 mm

- Fork opening

- 120 mm

- Interface

-

IO-Link-Device 1.1.3

Push-Pull/IO-Link NO(PNP)/NC(NPN) - Principle of operation

- Fork sensor

- Principle of optical operation

- Through-beam sensor

- Beam characteristic

- Divergent

- Light type

- LED, red light

- Connection

- Connector, M8x1-Male, 3-pin

- Housing material

-

Zinc, Die casting, black coated

PUR, PA 6.6 - Material sensing surface

- Film on glass

- Operating voltage Ub

- 10...30 VDC

- Approval/Conformity

-

CE

UKCA

cULus

WEEE

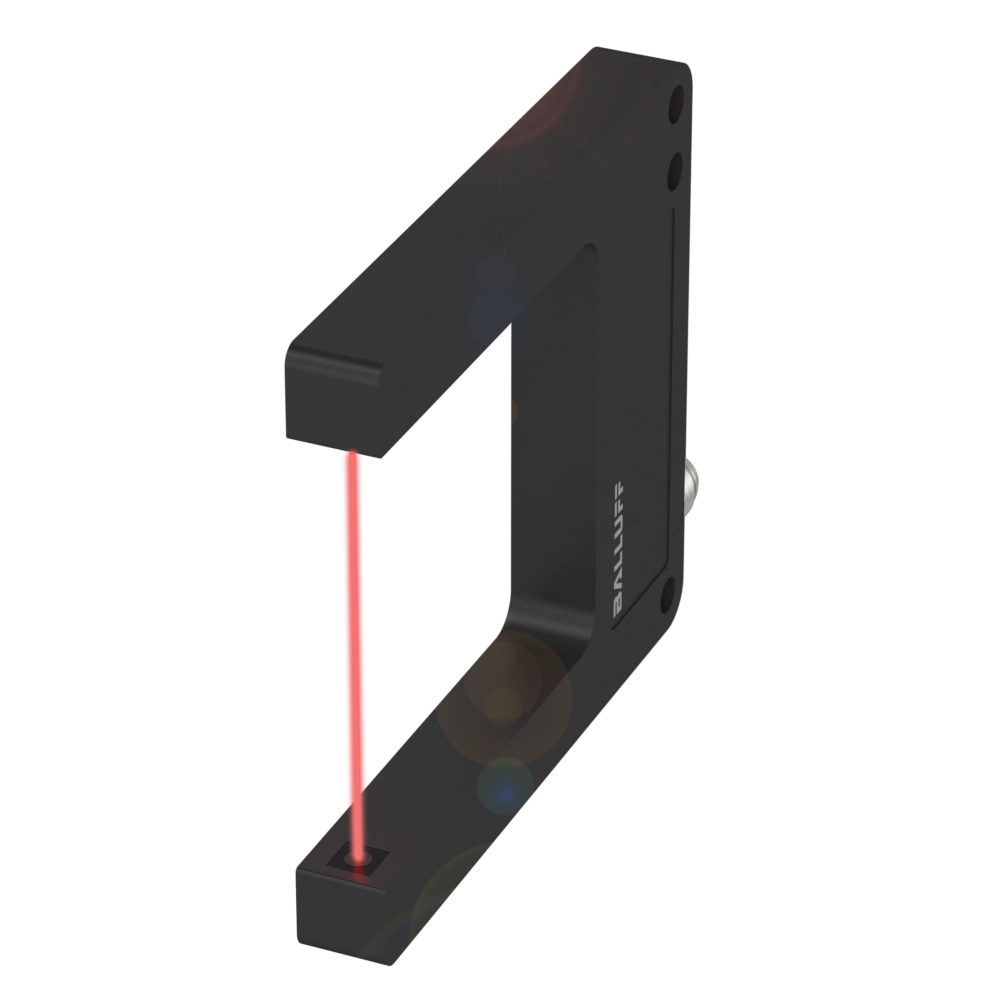

Standard metal fork light barriers

- Dimension

- 10 x 70 x 79 mm

- Fork opening

- 50 mm

- Interface

-

IO-Link-Device 1.1.3

Push-Pull/IO-Link NO(PNP)/NC(NPN) - Principle of operation

- Fork sensor

- Principle of optical operation

- Through-beam sensor

- Beam characteristic

- Divergent

- Light type

- LED, red light

- Connection

- Connector, M8x1-Male, 3-pin

- Housing material

-

Zinc, Die casting, black coated

PUR, PA 6.6 - Material sensing surface

- Film on glass

- Operating voltage Ub

- 10...30 VDC

- Approval/Conformity

-

CE

UKCA

cULus

WEEE

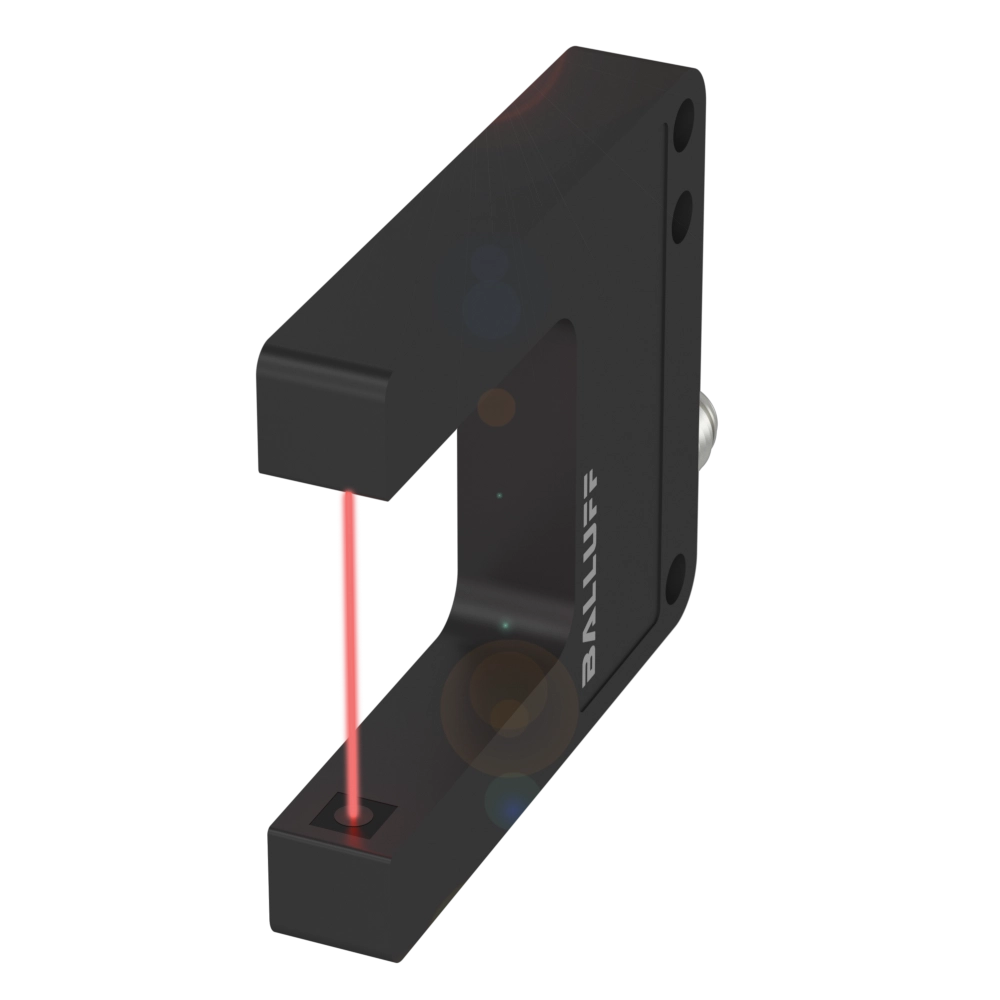

Standard metal fork light barriers

- Dimension

- 10 x 50 x 59 mm

- Fork opening

- 30 mm

- Interface

-

IO-Link-Device 1.1.3

Push-Pull/IO-Link NO(PNP)/NC(NPN) - Principle of operation

- Fork sensor

- Principle of optical operation

- Through-beam sensor

- Beam characteristic

- Divergent

- Light type

- LED, red light

- Light spot size

- Ø 0.85 mm Light exit

- Connection

- Connector, M8x1-Male, 3-pin

- Housing material

-

Zinc, Die casting, black coated

PUR, PA 6.6 - Material sensing surface

- Film on glass

- Operating voltage Ub

- 10...30 VDC

- Approval/Conformity

-

CE

UKCA

cULus

WEEE

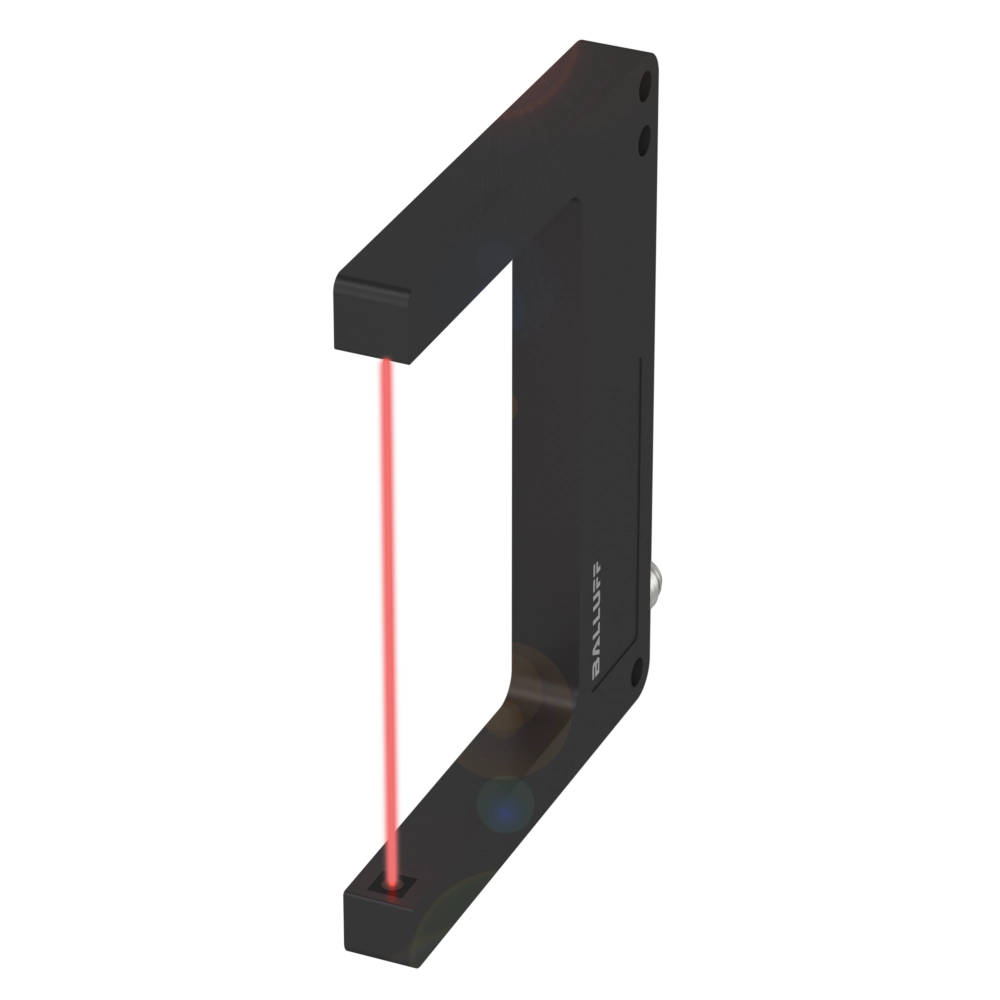

Standard metal fork light barriers

- Dimension

- 10 x 100 x 79 mm

- Fork opening

- 80 mm

- Interface

-

IO-Link-Device 1.1.3

Push-Pull/IO-Link NO(PNP)/NC(NPN) - Principle of operation

- Fork sensor

- Principle of optical operation

- Through-beam sensor

- Beam characteristic

- Divergent

- Light type

- LED, red light

- Connection

- Connector, M8x1-Male, 3-pin

- Housing material

-

Zinc, Die casting, black coated

PUR, PA 6.6 - Material sensing surface

- Film on glass

- Operating voltage Ub

- 10...30 VDC

- Approval/Conformity

-

CE

UKCA

cULus

WEEE