Reliable clamping processes and reduced downtime with ultrasonic sensors

DMG Mori relies on innovative sensor technology from Balluff for intelligent clamping devices for workpiece machining

Industry:Mechanical engineering / machine toolsCustomer:DMG MORI Pfronten GmbH

DMG Mori, a leading manufacturer of machine tools, produces over 50 machine types for various industries, including automotive and aerospace, at its site in Pfronten, Germany. In order to meet the increasing requirements and complexity of the components, the company relies on an ultrasonic sensor for short-stroke hydraulic cylinders from Balluff, which enables safe and collision-free machining and increases component quality. The partnership with Balluff supports DMG Mori in developing innovative and efficient manufacturing solutions and securing a competitive advantage.

The situation

DMG Mori is a manufacturer of high-precision machine tools and is represented in 44 countries. DMG MORI combines four pillars for the efficient and sustainable production of the future under the Machining Transformation (MX) concept: process integration, automation, digital transformation (DX) and green transformation (GX). Milling and milling-turning centers for comprehensive workpiece machining are manufactured at the Pfronten site. This product range extends from the versatile monoBLOCK series to XXL machines for components weighing up to 150 tons. DMG Mori also offers its customers turnkey solutions with innovative machining and clamping concepts. Customers come from a wide variety of sectors such as die mold, mechanical engineering, automotive, medical, energy, job store, semiconductor and aerospace.

The challenge

Changing market requirements and increasingly complex components require continuous further development of DMG Mori's products and technologies. Process integration in particular offers enormous potential for efficient production. The challenge is to develop machines that not only work efficiently and precisely, but also enable the combination of turning, milling and grinding functions. This saves resources and energy because the customer can produce finished workpieces with fewer machines. This increasing automation of processes requires more feedback from the machine: Has the correct component been inserted? Is the component correctly clamped? Can a clamping point be machined? Can the component be removed automatically?

The solution

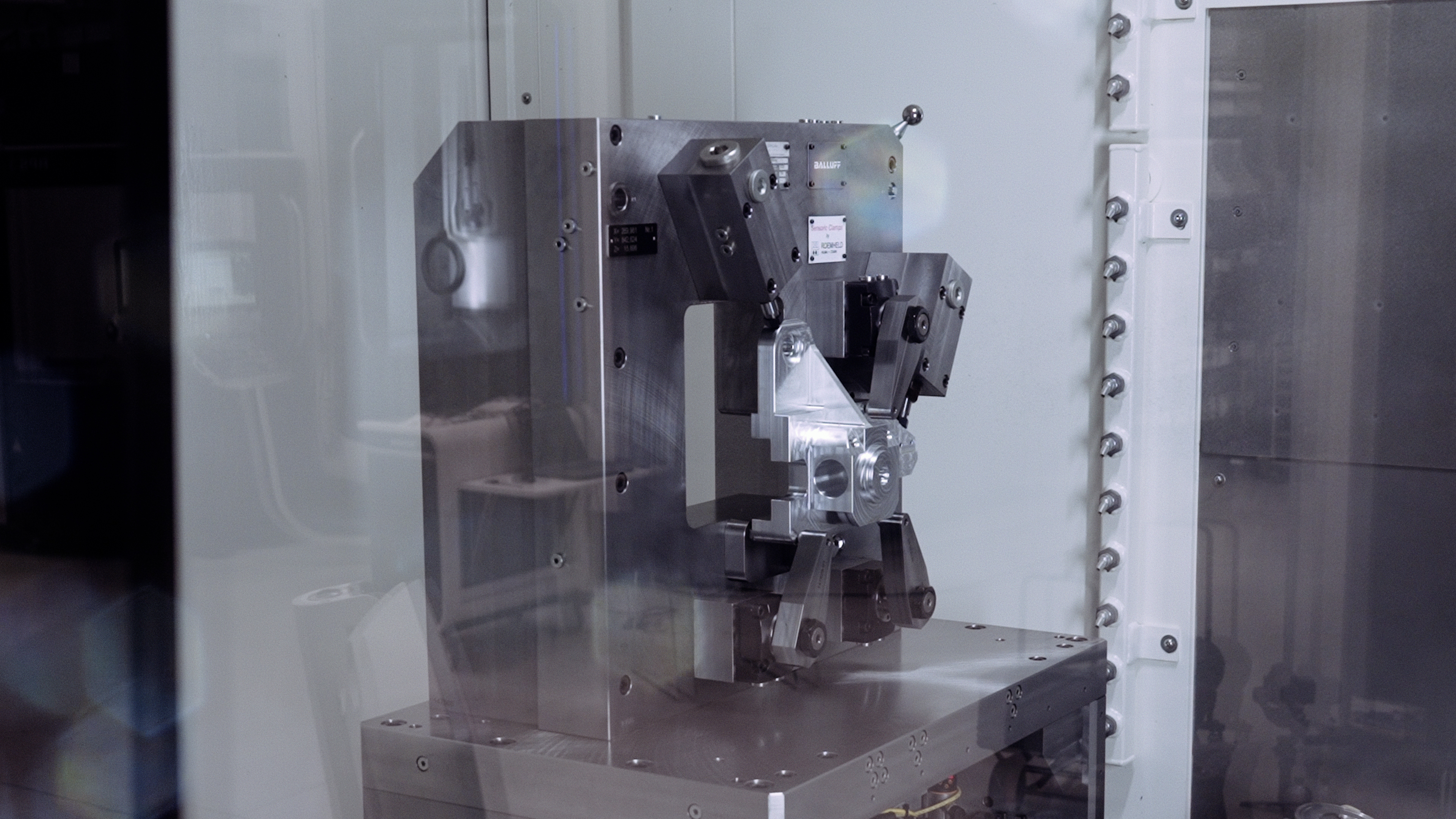

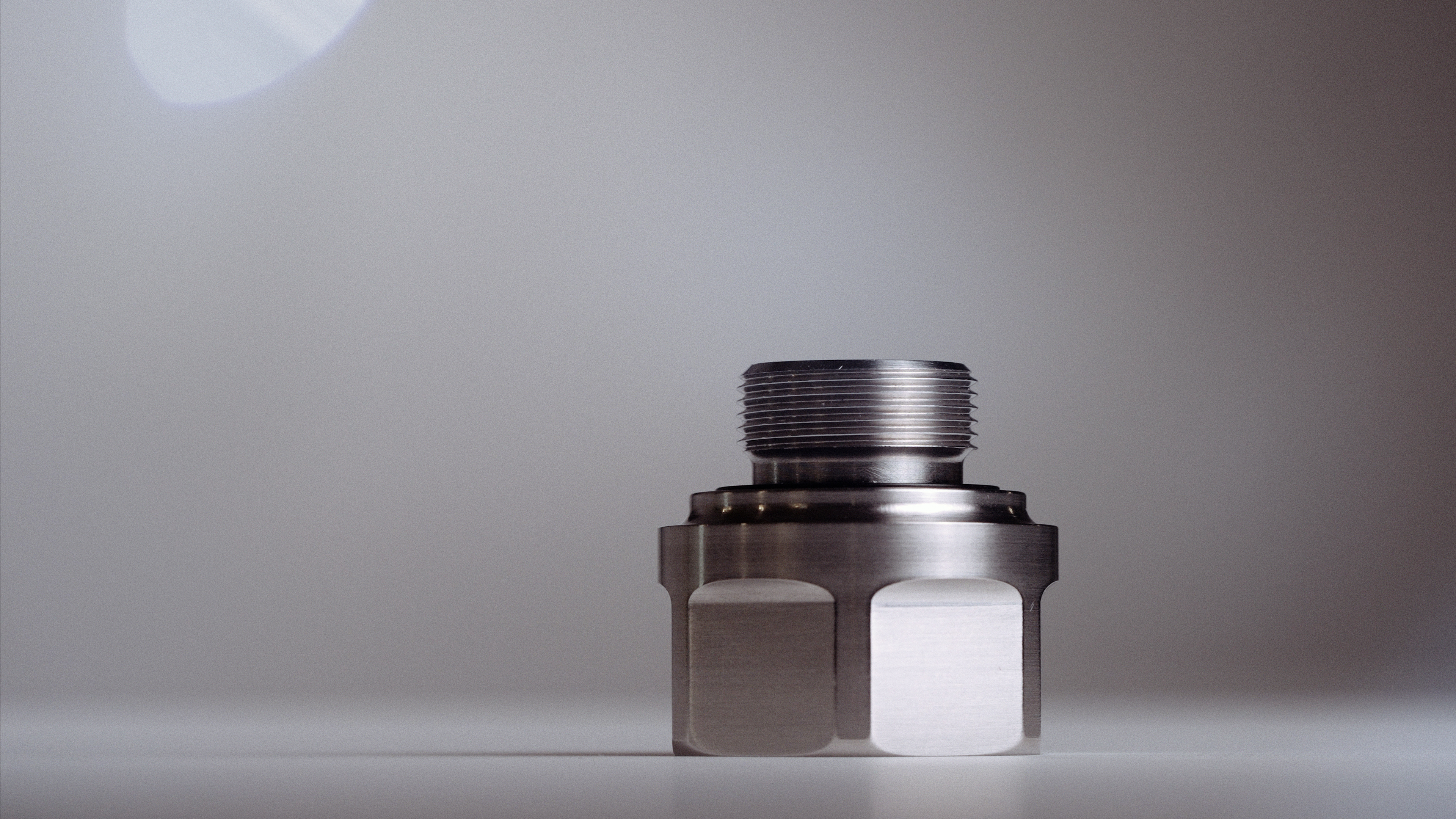

To overcome these challenges, DMG Mori has come to rely on the BFD ultrasonic sensor for short-stroke hydraulic cylinders from Balluff for about two years. This sensor is used both in the machines and on the machine table to ensure the reliable clamping of components.

The stroke monitoring in the clamping device enables safe and collision-free machining of the workpiece and supports automatic workpiece loading by robots. By monitoring the piston stroke, the exact position of the clamping element can be determined, which prevents collisions with the machine spindle or the robot gripper.

By using the BFD ultrasonic sensor, machine failures and damage to the system can be avoided. In addition, the information from the sensor helps to increase component quality by reducing reject rates.

The collaboration with Balluff is very cooperative and collaborative, and the speed of response and reliability of inquiries is particularly appreciated. Future steps with Balluff include the standardization of stroke monitoring for intelligent clamping devices and the use of the sensors on milling/turning centers.

Due to the small form factor, the sensor can be easily integrated into the clamping device. With the piston position data output and additional IO-Link data, it ensures process reliability.

Christoph Köhler, Technology Engineering, DMG Mori

The advantages of ultrasonic sensors for short-stroke hydraulic cylinders

- Maximum precision: reliable and continuous monitoring of the pistons over the entire clamping process

- Robust design: IP67 protection class and increased pressure resistance up to 350 bar

- Multifunctional interface: for flexible integration into almost any system architecture via IO-Link or analog current/voltage output (switchable)

- Condition monitoring: status monitoring of the sensor and the hydraulic system through additional information (e.g. signal quality, device status)

- Compensation in measurement: for adapting to changes in the quality and composition of the hydraulic fluid

Products in use

Ultrasonic sensors for short-stroke hydraulic cylinders

- Application

- Position monitoring in short stroke hydraulic cylinders

- Measuring range

- 0...80 mm

- Non-linearity max.

- ±250 µm

- Repeat accuracy

- ± 50 µm

- Pressure rating max.

- 350 bar

- Interface

-

IO-Link 1.1

Analog, voltage/Analog, current selectable 4…20 mA/0…10 V

Pin 4: Push-pull NO/NC

Pin 2: PNP/NPN/push-pull NO/NC - Operating voltage Ub

- 10...30 VDC

- Connection

- Cable with connector, M12x1-Male, 4-pin, 0.3 m, TPU

- Ambient temperature

- 0...85 °C

- IP rating

- IP67

- Approval/Conformity

-

CE

UKCA

cULus

WEEE - Secondary features for condition monitoring

- Internal temperature monitoring

- Secondary features

-

Identification

Device Discovery

Switching Profiles

Signal Quality Monitoring

Signal Delay

Switching Counter

Basic Statistics

Logic Blocks

Operating Hours Counter

Boot Cycle Counter

Voltage and Current Monitoring

Variant Configuration

Pin Assignment

Ultrasonic sensors for short-stroke hydraulic cylinders

- Application

- Position monitoring in short stroke hydraulic cylinders

- Measuring range

- 0...80 mm

- Non-linearity max.

- ±250 µm

- Repeat accuracy

- ± 50 µm

- Pressure rating max.

- 350 bar

- Interface

-

IO-Link 1.1

Analog, voltage/Analog, current selectable 4…20 mA/0…10 V

Pin 4: Push-pull NO/NC

Pin 2: PNP/NPN/push-pull NO/NC - Operating voltage Ub

- 10...30 VDC

- Connection

- Cable, 2.0 m, TPU

- Ambient temperature

- 0...85 °C

- IP rating

- IP67

- Approval/Conformity

-

CE

UKCA

cULus

WEEE - Secondary features for condition monitoring

- Internal temperature monitoring

- Secondary features

-

Identification

Device Discovery

Switching Profiles

Signal Quality Monitoring

Signal Delay

Switching Counter

Basic Statistics

Logic Blocks

Operating Hours Counter

Boot Cycle Counter

Voltage and Current Monitoring

Variant Configuration

Pin Assignment

Ultrasonic sensors for short-stroke hydraulic cylinders

- Application

- Position monitoring in short stroke hydraulic cylinders

- Measuring range

- 0...80 mm

- Non-linearity max.

- ±250 µm

- Repeat accuracy

- ± 50 µm

- Pressure rating max.

- 350 bar

- Interface

-

IO-Link 1.1

Analog, voltage/Analog, current selectable 4…20 mA/0…10 V

Pin 4: Push-pull NO/NC

Pin 2: PNP/NPN/push-pull NO/NC - Operating voltage Ub

- 10...30 VDC

- Connection

- Cable with connector, M8x1-Male, 4-pin, 0.3 m, TPU

- Ambient temperature

- 0...85 °C

- IP rating

- IP67

- Approval/Conformity

-

CE

UKCA

cULus

WEEE - Secondary features for condition monitoring

- Internal temperature monitoring

- Secondary features

-

Identification

Device Discovery

Switching Profiles

Signal Quality Monitoring

Signal Delay

Switching Counter

Basic Statistics

Logic Blocks

Operating Hours Counter

Boot Cycle Counter

Voltage and Current Monitoring

Variant Configuration

Pin Assignment