Faster cartoner changeovers with Balluff's Guided Changeover Solution results in 50% less downtime

Leading UK pharmaceutical manufacturer increases efficiency with Balluff's innovative changeover technology

Industry:Pharmaceutical manufacturingCustomer:A global leader in pharmaceutical manufacturing based in the UK

A leading global pharmaceutical manufacturer based in the UK wanted to improve its production efficiency, particularly for tablet blister packaging. Faced with growing market demands and production challenges, they required a breakthrough solution. After extensive evaluation and piloting, they decided to implement Balluff's Guided Changeover Solution (GCS) on a cartoner. This strategic move reduced changeover downtime by 50%, streamlined their production process, and significantly increased overall productivity. The customer achieved a quick return on investment, with the investment in Balluff's GCS being paid off in less than eight weeks.

Situation

In its high-demand, 24/7 operation, the company faced the challenging task of managing eight different carton sizes and various blister pack dimensions. With twenty changeover points, each format change was a significant bottleneck, making downtime reduction critical to maintaining production quotas.

Challenge

The variety of carton and blister sizes resulted in inefficient changeovers, creating a major bottleneck in the continuous production line. With changeover times averaging 20 minutes, this inefficiency threatened the company's ability to meet stringent production targets and market demands.

Solution

The company implemented Balluff's Guided Changeover Solution (GCS) on the cartoner. This involved three steps:

Identify the switch points or center lines.

Select and install the appropriate sensors, including Balluff's Digital Position Indicator for precise adjustments.

Create step-by-step operator instructions in the GCS software.

After a brief training session, the operators used the system immediately. The software guided them through the format change process, and the sensors provided instant feedback on the position of the change points, making it easy to set the correct lengths, heights and widths.

How does it work?

Balluff's GCS integrates seamlessly with the cartoner, guiding the operator through each changeover with real-time feedback. The system's sensors, including photoelectric and inductive proximity sensors, along with the digital position indicator, ensure precise adjustments and consistent results, virtually eliminating the need for post-changeover fine-tuning.

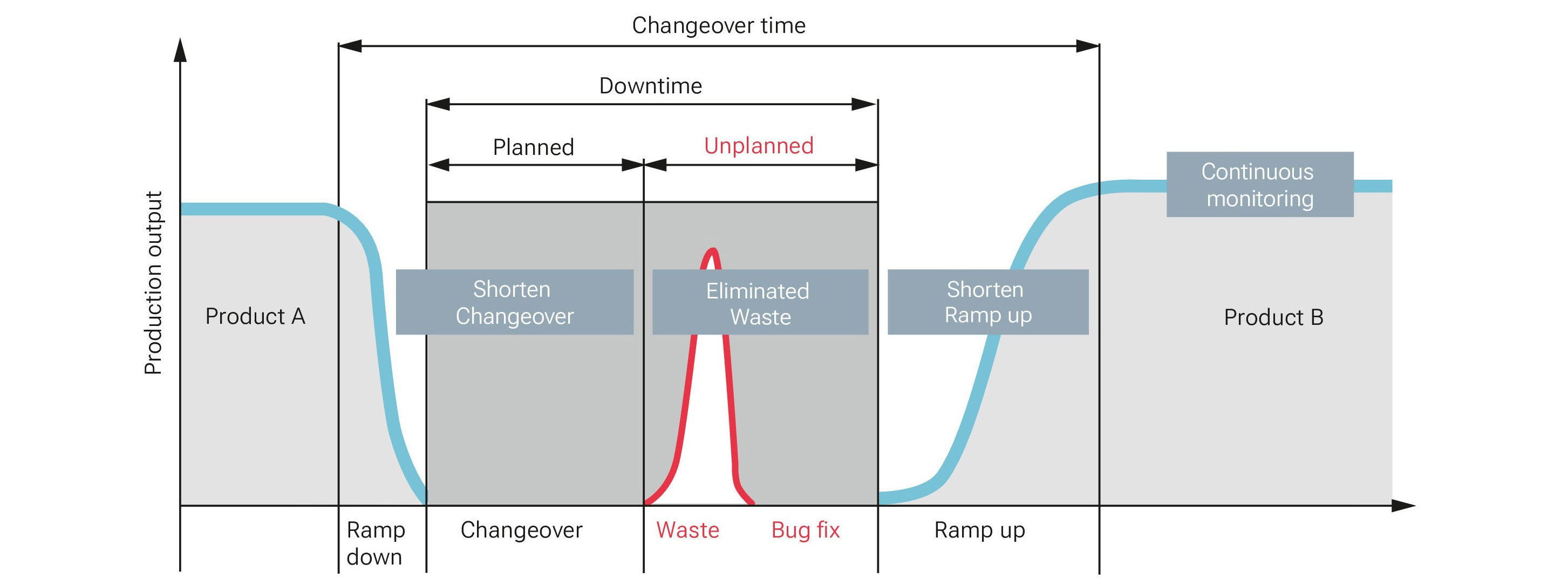

The Guided Changeover Solution significantly shortens changeover times, eliminates waste, and ensures fast, error-free ramp-up, while continuous monitoring optimizes ongoing production processes to enhance Overall Equipment Effectiveness (OEE).

The Guided Changeover Solution significantly shortens changeover times, eliminates waste, and ensures fast, error-free ramp-up, while continuous monitoring optimizes ongoing production processes to enhance Overall Equipment Effectiveness (OEE).

Products in use

Implementing Balluff's Guided Changeover Solution has significantly streamlined our changeover process, reduced downtime and improved overall efficiency. The quick return on investment has encouraged us to implement this solution on additional machines.

Maintenance Manager at UK-based pharmaceutical manufacturer

Benefits

- Reduced changeover downtime from 20 minutes to less than 10 minutes

- Achieved a reduction of approximately 10 minutes per format change

- More than 15 size changes per week, resulting in a rapid ROI with a return on investment of less than 8 weeks

- Minimized waste and virtually eliminated startup time

- Extended machine life with minimal investment by retrofitting the GCS without disturbing the original controls

Contact Balluff today to learn how the Guided Changeover Solution can optimize your production process, reduce downtime, and improve efficiency for your operations.