13.07.2022

Technology partnership drives digitization at special machinery manufacturer

ruhlamat has been installing innovative sensor technology by Balluff in its machines for decades. In the course of digitization, the aim now is to further add data-based services to the portfolio.

Constructing specialized machinery means fulfilling special requests. It’s all about project business and understanding multifaceted customer requirements. As a longstanding specialist in this field, ruhlamat, which is based in the Marksuhl borough of the German town of Gerstungen, offers just this: individually tailored and standardized machine solutions. “All our work is aimed at developing the innovative and individual solutions our customers really need,” Thomas Mack, President and CEO at ruhlamat, emphasizes, adding, „Customer satisfaction is our highest priority.“ This can also be understood as a reference to a well-thought-out digitization strategy. After all, if you want to impress customers with comprehensive services in fiercely competitive markets and offer additional customer benefits, you must master sensor technology and data processing first. ruhlamat works on applications for systems control, traceability, manufacturing execution systems (MES), the Industrial Internet of Things (IIoT), and semi-automatic data processing (Advanced Analytics).

ruhlamat GmbH was founded in the early 1990s and has its roots in the tradition-steeped Uhren- und Maschinenfabrik Ruhla, which manufactured clocks and machinery. At locations in Germany, China, India, Mexico, the Czech Republic, Lithuania and Malaysia, a total of 1,200 employees serve customers in the automotive and medical technology industry, public administration and other special mechanical engineering sectors.

Adding value along the entire process

ruhlamat is not the only one who can look back on a long tradition: The sensor and automation specialist Balluff celebrates its 100th anniversary this year. The company has maintained a close customer relationship with the special machinery manufacturer for decades, with ruhlamat installing the first inductive sensors in the mid-1990s. „We use Balluff products because they provide us with a decisive cost-benefit advantage. It is the entire process from installation and wiring all the way to the programming of the controls that adds value for us,“ summarizes Michael Trebig, Production Manager at the special machinery manufacturer, praising the balancing act that Balluff has mastered: the precision and durability of the solutions on the one hand, and cost optimization and reliability on the other.

Driving digitization

Inductive and photoelectric/optical sensors, position sensors for pneumatic cylinders and grippers, capacitive sensors, inductive couplers, encoder systems, RFID systems, fieldbus communication modules, connectors – this is just a small selection of the Balluff components and systems that ruhlamat relies on. For the same reason, the Balluff IO-Link portfolio has been in use. In the beginning, this was due to economic reasons: installation costs could be reduced thanks to simplified topologies. But increasingly, the possibility of accessing more operating data via sensors in machine operation is also being put to use, systematically driving the comprehensive digitization of the ruhlamat machines.

Customer requests come first

"Since many machines are manufactured on a customer-specific basis, we have to find the optimal sensor for each individual project. Wherever possible, we use assemblies and technologies that are already successfully in use at ruhlamat,“ Knut Völker, the Balluff Sales Associate in charge reports and adds: „The extensive Balluff sensor portfolio with its pronounced strength in the field of miniature sensor technology is what distinguishes the ruhlamat machinery.“ Sven Ehrich, CTO at ruhlamat, points out another advantage: „Balluff products are listed on the release lists of our customers who are automotive manufacturers and automotive suppliers. That's why we prefer them."

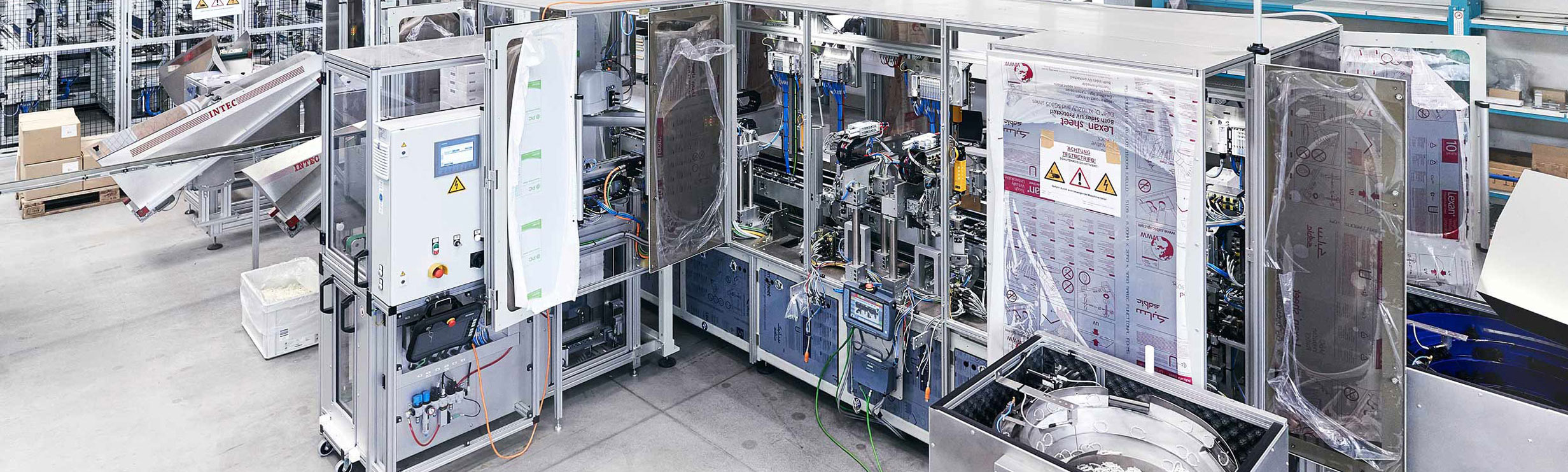

Testing machine ruhlamat PowerPerso ID3 for the personalization of ID cards, chip cards, and passports. The consistently modular design enables fast commissioning. Balluff technology supports the modularization.

ruhlamat primarily serves four markets: card and passport systems, assembly and automation systems, OEM production, and contract manufacturing of high-value parts. The special machine manufacturer is a leading supplier of systems for the personalization of ID cards, chip cards, passports, and electronic passports. The focus in assembly and automation systems is on the production of small to medium-sized assemblies. Linear transfer systems, manual workstations, rotary indexing systems, robotic applications, 2D process solutions as well as test and inspection systems are used. As an experienced partner, ruhlamat also develops OEM machines and exclusively manufactures them according to customer requirements.

"Since many machines are manufactured on a customer-specific basis, we have to find the optimal sensor for each individual project.“

Knut Völker, Sales Associate at Balluff

A/C conversion with “unbeatable” advantages

Balluff sensors, RFID systems or distributors are primarily in use, such as inductive sensors for the request of metallic features for the coding of part carriers. Capacitive sensors are also used to detect switching lugs to control reels and unwinding mechanisms (nonwoven reel masking machine).

Optical sensors on probes or reflex light barriers are used to check the presence of parts on the carriers. "The magnetic field sensors of grippers mounted on a rotary table must be supplied with power and coupled with the control system. Power feed-through is difficult due to the small installation space. But the Balluff LF data coupler solves this problem contactless,“ says an elated Sven Ehrich and points out the condition monitoring system BCM as another example: “We capture environmental data from our PowerPerso ID3 passport personalization machine via switching power supplies, the IO-Link and distribution modules. This works extremely well."

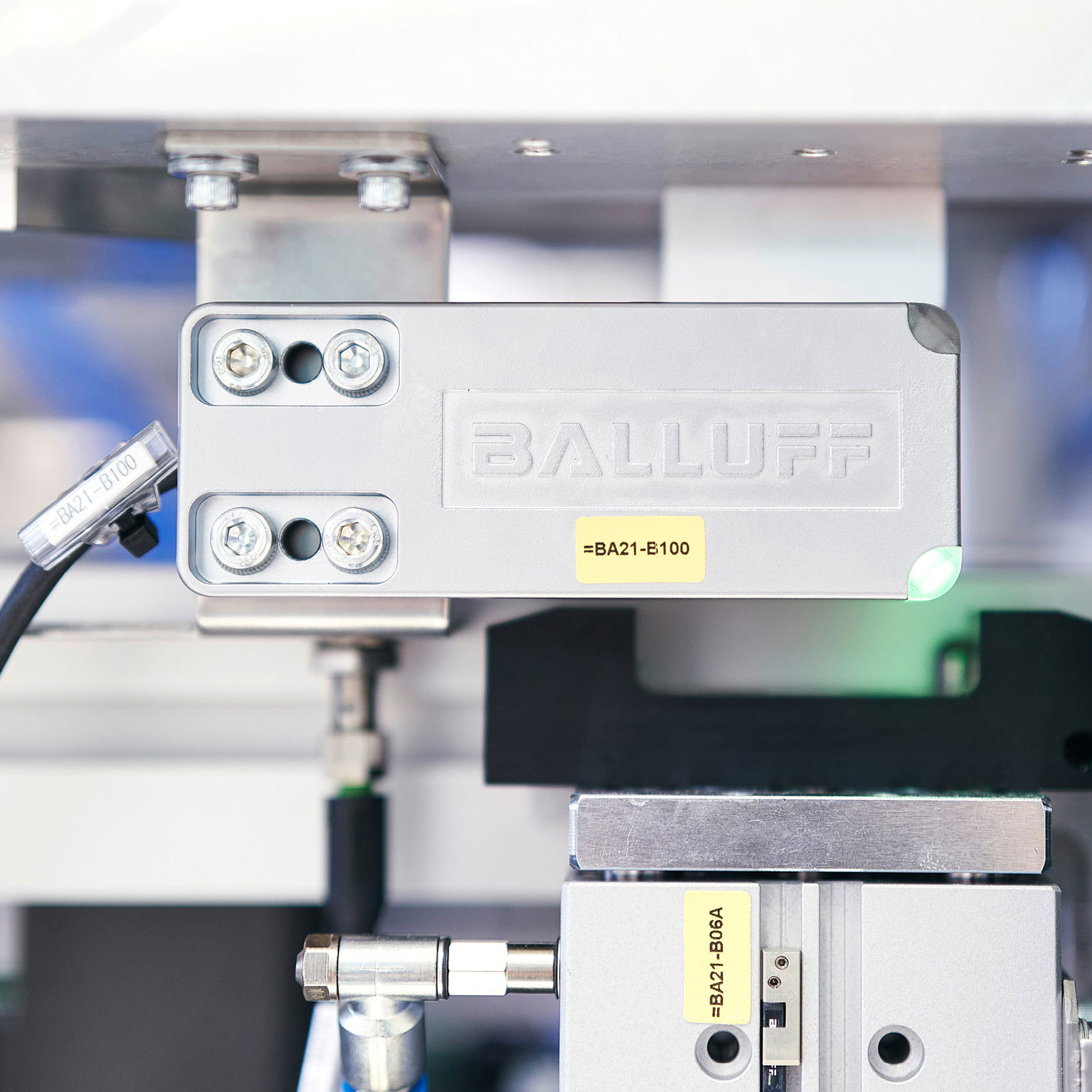

RFID reader by Balluff, reading the part carrier.

Michael Trebing is also impressed with the Balluff portfolio: “The sensor signals are translated into digital ones through IO-Link so they can be processed in the PLC. The Balluff technology supports the work with prefabricated cable lengths. This saves time and material when wiring the modules. And it is not necessary to wire them to the control cabinet – an unbeatable advantage."

Global player meets global player

Much like ruhlamat, Balluff opened up to international markets at an early stage. In the early 1980s, the company began to continuously expand its production and sales network. Today, Balluff serves all important markets in Europe, Asia and North and South America, totaling 68 countries. “The fact that Balluff components and services are available worldwide is a great advantage for us. Machines that are commissioned here in Marksuhl are often a combination of on-site assembly and modules from China, for example. The important thing here is that all the installed components also work perfectly together," emphasizes the production manager. Michael Trebing knows how crucial high-quality and globally available components are – after all, he has been working in the field of special machinery for more than 25 years.

Expanding services with digital twins

In close coordination with the Chinese subsidiary, the ruhlamat headquarters in Marksuhl is working on a comprehensive digitalization agenda. "For our customers, we offer full service from a single source," explains Managing Director Thomas Mack, adding, "Of course, for us, comprehensive service includes more than just manufacturing and installing our special machines. In the future, outstanding digital services will distinguish us even more for providing our customers worldwide with situation-specific offers, even after the machines have been delivered. And for this we need the digital twin of every machine delivered." This is why Balluff components are extensively installed in the machines: Digitization relies on data, and Balluff technologies reliably capture and transmit it. This way, data becomes valuable information that can be evaluated in higher-level systems such as ERP or MES.

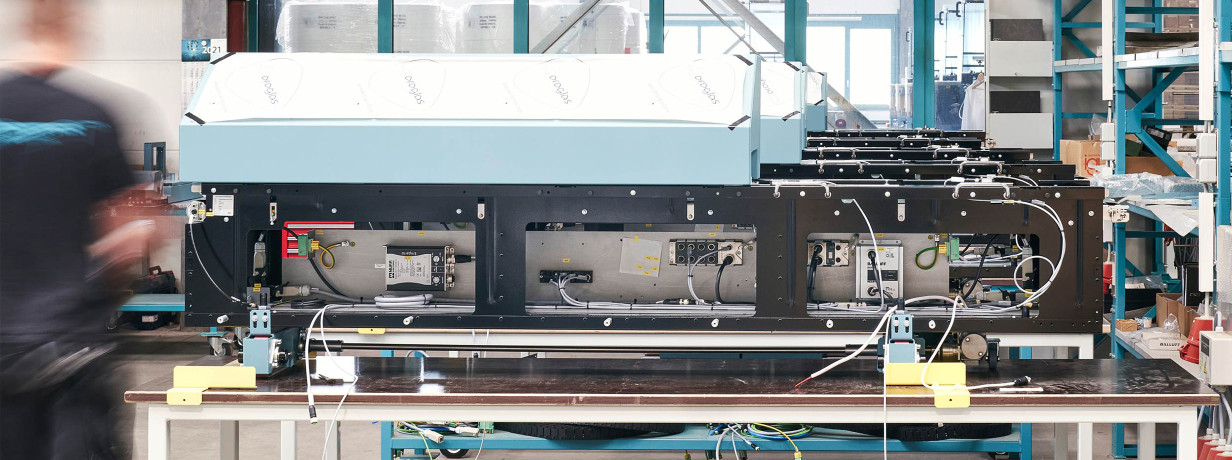

This ruhlamat machine produces heating control valves for the hot water distribution in underfloor heating systems. It occupies the area of half a production hall.

This ruhlamat machine produces heating control valves for the hot water distribution in underfloor heating systems. It occupies the area of half a production hall.

Ready for the future with digital building blocks

“Our goal is to modularize our customer-specific solutions to a greater extent and to continue to base them on standards. Our own machines’ product structure already follows a modular design. Now we have to apply this approach to our assembly technology. After all, we can only be successful in the long term if we succeed in creating and networking system components across the board,” says CTO Sven Ehrich. This is why ruhlamat has issued construction guidelines in order to standardize special machinery as much as possible. Balluff’s Knut Völker weighs in, saying: „We are working together on the revision of the ruhlamat standard assemblies, so that cost-optimized solutions can be reused.“

In line with the Industrial Internet of Things

“IIoT readiness” is a high priority in the special machine manufacturer’s design department. If the designer has a choice of two sensors with equivalent properties, he is encouraged to use the sensor with the higher IIoT readiness, even if this feature is currently irrelevant for the specific application. "This way, we ensure that diagnostics on the systems are also possible downstream without first having to be technically retrofitted,” explains Sven Ehrich. Initial promising trials are already underway with the BCM condition monitoring sensor by Balluff. ruhlamat is in close contact with Balluff to share their opinion on the Smart Automation and Monitoring System (SAMS) in terms of retrofitting it into existing applications. Based on its broad product portfolio and the expertise and many years of experience in automation, Balluff continues to develop new, IIoT-enabled solutions. When developing new products for the IIoT, Balluff uses open standards as well as standardized interfaces and protocols. These components and tools are compiled for customers at one glance in the so-called Balluff IIoT Selection.

Partners for the long term

ruhlamat has already invested in Balluff’s Condition Monitoring Advanced Service Package – and this is just the first step: “The long-term technology partnership with Balluff helps us follow our path to digitization with the greatest possible benefit for us and our customers,” says President and CEO Thomas Mack.

“The long-term technology partnership with Balluff helps us follow our path to digitization with the greatest possible benefit for us and our customers.“

Thomas Mack, President & CEO at ruhlamat