- Sensor and networking excellence for Packaging, Food, Beverage, Pharma, and Personal Care industries

- Advancing battery manufacturing automation: Achieving superior efficiency and quality

- Automobile industry and suppliers

- Efficient metalworking using sensor and automation technology

- Mobile Equipment

- Steel and Metallurgical Industry

- Life Science

- Drive Technology

- Plastic Industry

- Energy Production

- Intralogistics automation

- White goods

- Electronics industry

- Tire Industry

- Traffic Engineering

- Robotic sensing: Precision and efficiency in robotics automation

- Automation in the semiconductor industry

- Components for hydraulics and pneumatics

Robotic sensing: Precision and efficiency in robotics automation

Sensors, networking, and traceability solutions for optimized manufacturing processes

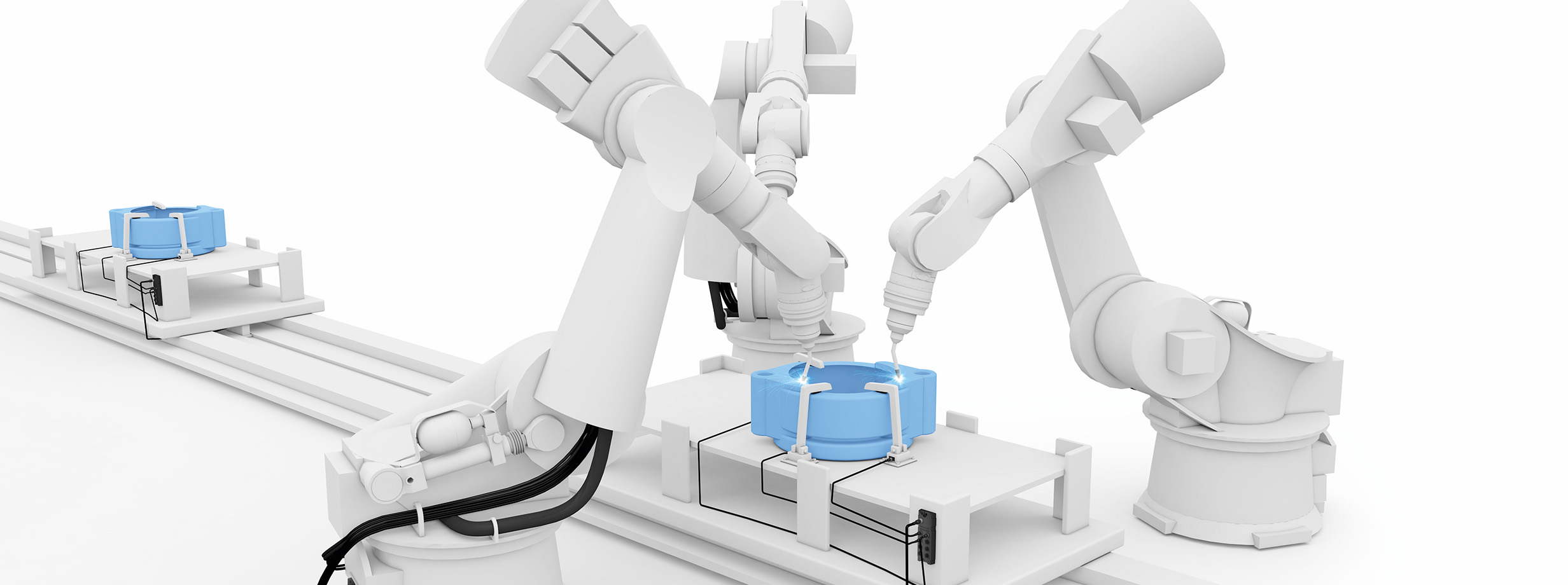

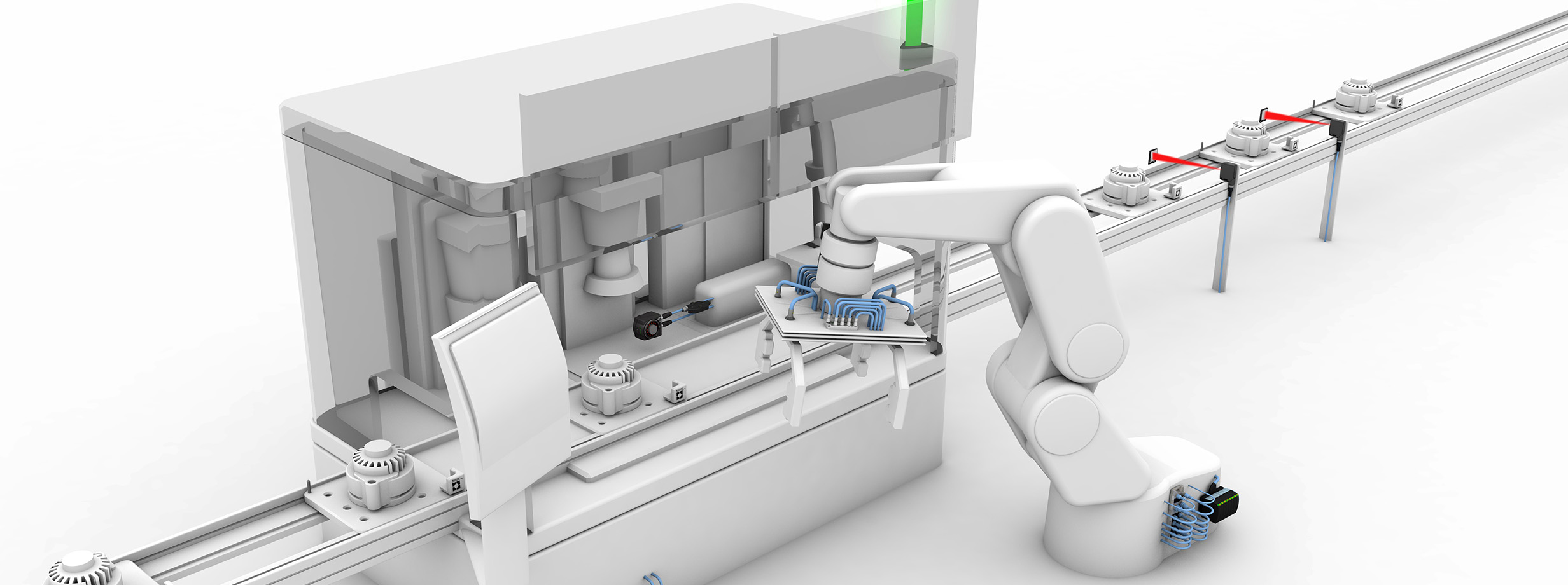

Robotic manufacturing and automation require high precision, speed, and flexibility. Balluff supports these requirements with sensors and components that improve the reliability and efficiency of automation. Designed for manufacturers, machine builders and system integrators, our technologies enable smoother operations in industries such as automotive, battery manufacturing, packaging, and electronics.

Balluff helps you achieve maximum operational efficiency for your robotic operations by providing robust sensors for applications such as welding, washdown and clean room environments, networking solutions for streamlined data flow, RFID and code readers for manufacturing traceability, and condition monitoring sensors to enable predictive maintenance.

In addition to improving efficiency and product quality, our products enable precise and flexible robotic operations, such as fast, error-free end-of-arm tool changes, accurate workpiece positioning, and precise motion and tracking of mobile robots and conveyors.

Unlocking efficiency and precision in robotic material handling

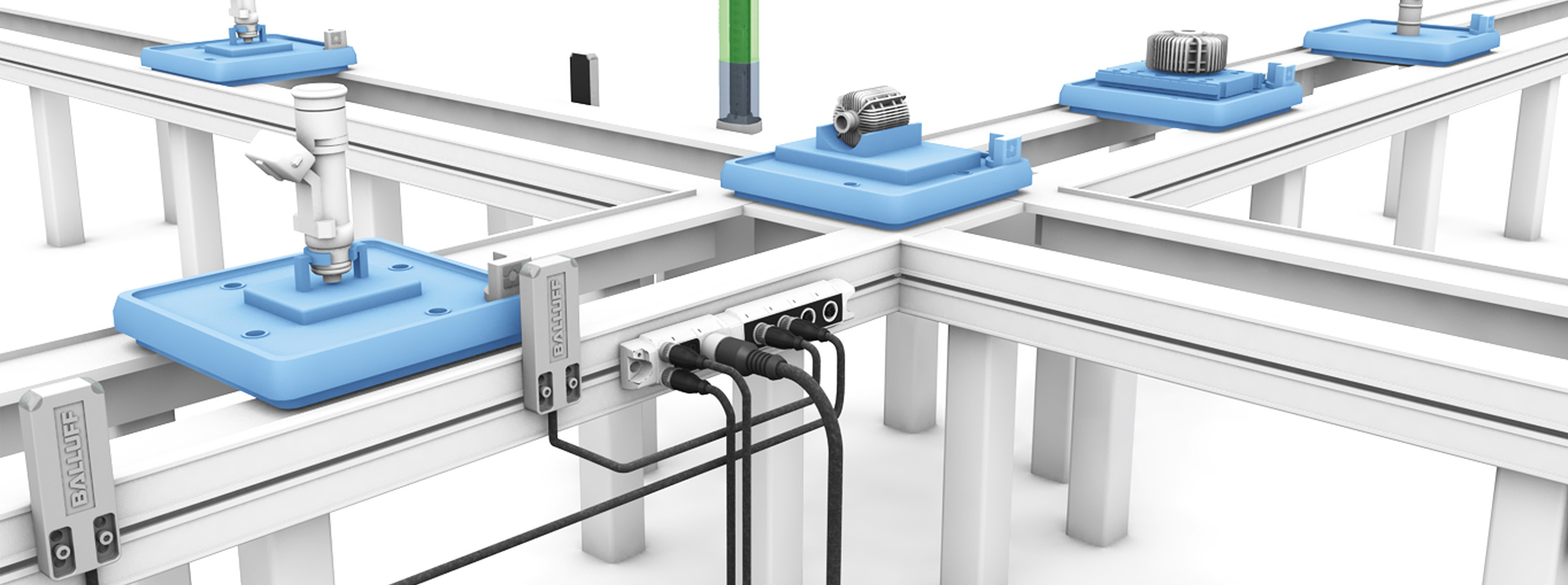

Our 3D visualization shows how automation technology makes robotic material handling safer, more efficient, and error-free. From condition monitoring sensors, network blocks, RFID, SmartLights, photoelectric sensors for object detection, to inductive couplers that eliminate wear on electrical connections.

1

Overview: Efficient pick-and-place

1

Here you can see how Balluff components work together in practice to enable a smooth and precise material flow in robot-supported pick-and-place applications.

Click on an element to get detailed information.

2

UHF RFID tags

2

BIS U UHF RFID for 860 to 960 MHz offer a wide variety of UHF carriers for diverse applications.

For example, they can be used for direct mounting on metal, tool identification, high temperature applications, and disposable solutions as self-adhesive UHF labels.

3

UHF read/write heads and antennas

3

Our UHF read/write heads are scalable, allowing flexible design and implementation of your identification tasks, for example on conveyor systems, gateways or storage systems.

They are available in various versions suited for different ranges and applications.

The effective range depends on the chosen combination of read/write head or antenna and the UHF carrier as well as the configuration of the evaluation unit.

4

UHF evaluation units

4

Our frequency independent evaluation unit, BIS V, streamlines your inventory management. It is highly versatile and supports mixed operation of all product families (BIS M, BIS L, BIS C, BIS U).

Each BIS V unit can operate up to four read/write heads simultaneously. Moreover, it supports all the most common global standard industrial networking protocols for applications in all kinds of industrial applications.

5

SmartLight

5

The SmartLight LED stack light signal column, featuring an IO-Link interface, displays important or critical conditions such as machine status, fill level, temperature, or equipment position, using a flexible spectrum of multicolored LEDs.

Each color is individually configurable, providing clear signals for a range of machine conditions from normal to critical. Trends and variations in physical parameters are intuitively represented by the color scale.

6

Network modules

6

Designed for seamless connectivity of sensors and actuators, Balluff’s new generation of network modules offers highly versatile parameterization and diagnostic features via an integrated display, LEDs and web server. They are IIoT-capable with support for REST API and MQTT. Three classes of IO-Link masters offer the choice of Entry, Standard, and Advanced performance levels to make sure to fit your individual needs. Multi-protocol versions are available in all classes which support the most common industrial ethernet networks. Metal, plastic, and washdown housings enable you to use the IO-Link masters in any industrial environment.

The modules feature large, bright and easy to read status LEDs, saving time during installation, maintenance or fault diagnosis. With an output current of up to 2 A, these modules can drive nearly any load. Additionally, each output includes overload protection with an LED indicator and a memory function for troubleshooting.

Moreover, the robust full metal housing is built to withstand exceptional stresses, delivering consistently powerful performance.

7

Safe I/O module

7

Balluff’s safe I/O module bridges automation and safety technology using IO-Link. With Safety over IO-Link, you get the best of both worlds.

Integrating industrial safety technology is now easier than ever. Connect nearly any safety device using standard, low-cost M12 cables, while central parameterization through the controller streamlines the process.

Safety critical information is transmitted directly to the controller via the master, and the use of Profisafe over Profinet guarantees secure communication.

8

I/O modules

8

Balluff’s I/O modules interface binary and analog sensors and actuators with the control system via the IO-Link protocol.

By using these modules, you can significantly reduce wiring complexity. They also offer additional functions for signal preprocessing and advanced diagnostic capabilities. With various form factors and connection techniques, they provide solutions for a wide range of requirements, even in extreme environments.

9

Inductive couplers

9

Fixed wiring of sensors and actuators has its drawbacks: in automation, cables, contacts, and connectors are frequently subjected to heavy use, leading to fatigue and breakage that can result in costly machine downtime.

Our inductive couplers overcome these challenges by transmitting data and power contactlessly across an air gap, thus eliminating mechanical wear.

This enhances system availability, shortens cycle times and increases process flexibility. Additionally, these units can be quickly disconnected, are easy to handle and require no maintenance, allowing for rapid adaptation to new requirements.

10

Optoelectronic sensors

10

Balluff’s optoelectronic sensors reliably detect the presence and position of objects. They can also accurately monitor shape, color, distance and thickness. Compared to proximity sensors using inductive or capacitive technologies, they offer a significantly larger detection range.

Balluff provides an extensive product range, offering sensors in various light types, from red light and infrared to laser technology. Our portfolio includes sensors with different ranges, with or without background suppression, and in various designs.

Mini sensors, color sensors, light curtains and contrast switches for specialized applications complete our offering, ensuring not only the highest reliability but also maximum flexibility.

11

Condition Monitoring

11

Balluff’s condition monitoring sensors capture various physical parameters, such as vibration, temperature, humidity and ambiant air pressure, process them and deliver the desired data via IO-Link to an overarching system.

The standardized IO-Link protocol enables convenient parameterization of the sensors, and the sensor's evaluation can be individually adapted to the application. With flexible process data configuration, up to five measured or preprocessed data points can be freely set up and transmitted cyclically.

As a result, these sensors significantly contribute to the efficient and uninterrupted operation of any plant, thereby enhancing overall plant effectiveness.

When you choose Balluff, you are partnering with a leader in industrial automation technology that is committed to advancing your robotic operations and machines to drive productivity and innovation in your business.

Tom Knauer, Global Market Segment Manager Robotics & Automation

Highlight products for robotics applications

Specialized sensors and components designed to tackle the unique challenges in robotics automation. From digitizing data flow with IO-Link to condition monitoring sensors, our products help you boost your Overall Equipment Effectiveness (OEE) and ensure production quality.

Industry brochure robotics automation

Take a deep dive into robotics applications where our sensors and components can help you get the most out of your processes, whether you are a systems integrator, plant engineering manager, robot manufacturer, or end-of-arm tooling supplier.

Robot cells and networking

End of arm tooling

Positioning

Process integrity

Handling

Welding

Mobile robots and transport systems

Robotic sensors: The key to efficient robotics automation

Robotic sensors are critical to automation, enhancing the perception, responsiveness and precision of robotic processes. Our sensors can detect environmental conditions such as position, presence, movement, pressure and temperature in real-time, transmitting this data directly to control systems. In robotics automation, sensors enable precise positioning of workpieces, safe, fast end-of-arm tool changes and accurate navigation of mobile robots.

By seamlessly integrating sensors into automation solutions, companies can increase the efficiency and flexibility of their operations, minimize downtime and ensure higher product quality. Robotic sensors are not only fundamental to optimizing existing systems but also a driving force for innovation in industrial automation.

Explore the industries where our robotic automation components take center stage

Questions? Ask our robotics automation experts!

Downloads

-

Industry brochure industrial robotics

-

Industry brochure intralogistics

-

Industry brochure battery industry

-

Industry brochure white goods – household appliances

-

Industry brochure assembly and handling

-

Industry brochure welding resistant sensors