- Sensor and networking excellence for Packaging, Food, Beverage, Pharma, and Personal Care industries

- Drive Technology

- Steel and Metallurgical Industry

- Life Science

- Efficient metalworking using sensor and automation technology

- Mobile Equipment

- Plastic Industry

- Automobile industry and suppliers

- Intralogistics automation: improve efficiency and throughput

- Energy Production

- White goods

- Electronics industry

- Advancing battery manufacturing automation: Achieving superior efficiency and quality

- Tire Industry

- Traffic Engineering

- Robotic sensing: Precision and efficiency in robotics automation

- Automation in the semiconductor industry

- Components for hydraulics and pneumatics

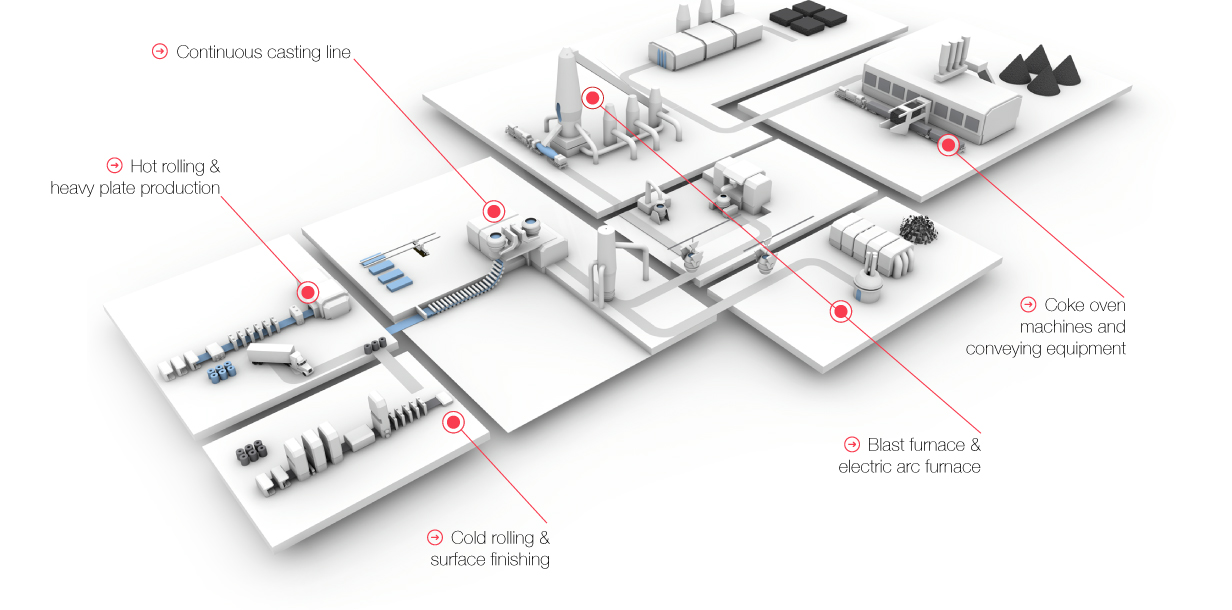

Steel and Metallurgical Industry

Reliability and flexibility from a single source

Whether in the automobile industry, aviation and aerospace, energy production, construction or medical technology – steel plays a key role everywhere. It is extremely adaptable and meets the highest requirements. Its consistent quality when it comes to corrosion protection, low weight or great ductility ensures the success of complex processes and enables repeatability even under the harshest conditions.

Linking optimal quality management with efficient and reliable processes requires equipment and machines of the highest quality. Preferable equipped with first-class sensors and systems as well as the appropriate network technology from Balluff. High-temperature, shock and vibration proof, extremely rugged and reliable, our technologies especially developed for harsh environments, ensure maximum equipment up-time and machine performance in every phase.

Coke oven machines and conveying equipment: Get off to the optimal start in steel production

No ifs or buts: the highest priority in a steel plant is an uninterrupted process. Meet these high requirements from the very start. Balluff provides you with highly reliable solutions for a wide variety of tasks pertaining to coking plant machines, the coke oven battery and conveying equipment.

Just where things get really hot is where our rugged BTL magnetostrictive linear position sensor will get the job done at up to 100 ºC. It reliably controls all movements during oven charging in the coking plant. The oven controller is monitored by an Ex protected position measuring system which is perfectly designed for the gas environment. And for tracking the relative positions of larry cars, pusher cars, and transfer cars at the coke oven battery, we offer our Industrial RFID, which boasts a large read/write distance, fast data transmission, high data integrity, and operates without line-of-sight contact.

Blast furnace and electric arc furnace: Continuously manage magnetic fields and high temperatures

At no other place in the steel mill is process reliability as important as at the blast and arc furnaces. For once it is commissioned, a blast furnace is used around the clock over the course of years – hardly possible without continuous water cooling and replenishment.

And just as critical to the process: absolutely reliable immunity to magnetic fields, safe inflow and outflow of gas when producing pig iron in the blast furnace, exact positioning of the electrodes in the arc furnace as well as controlling the conveying equipment. These are reasons enough to focus on every single detail.

Balluff solutions take over control functions at critical positions: our pressure sensors reliably measure water and air pressure. Magnetostrictive linear position sensors or inductive standard sensors monitor flap opening for controlling air intake and exhaust in the blast furnace. And in the electric arc furnace weld-spatter-resistant and magnetic field-immune inductive sensors check the precise position of the electrodes before they are properly gripped, assisted by color sensors.

Continuous casting line: Maximum flexibility for various formats

As efficiency increases, so do the demands on continuous casting lines. Large forces, vibrations and shock have to be controlled in the continuous casting line: at the ingot mold movement for the homogeneity of the fluid metal or at the walking-beam for transport of slabs or billets. Comprehensive monitoring measures are, therefore, indispensable.

But the investment pays off, because only in this way can you prevent costly pouring interruptions before they happen, improve the quality of the product, and increase your offering variety.

The steel quality is determined at the continuous casting segments. The desired properties are achieved depending on the gradient, temperature and time of the reshaping. Therefore, maximum flexibility and peak reliability are required for the technology. Balluff sensors and systems provide you with security and guarantee a continuous process for a wide variety of product formats. Thanks to automatic format changing, every new customer requirement can be responded to in no time.

Hot rolling and heavy plate production: For a continuously reliable process

Hot rolling and heavy plate production are always associated with great forces. Shock, vibration and applied forces are typical here: for example, when rolling and cooling or cutting to finished dimensions along with the accompanying inspection steps. The equipment also needs to withstand moisture on the rolling mill caused by water cooling.

As a heavy plate producer you need high-performance equipment and suitable regulating devices at every process stage. With Balluff you get first-class technology to master all the stages from the slab to the coil: fieldbus modules, temperature sensors, position measuring systems, industrial RFID systems and vision sensors.

Cold rolling and surface finishing: Maximum precision for the finish

Before the steel leaves the plant, it needs to be finished as much as possible for future use: rolled into a sheet, wire or rail and surface finished. Even the slightest flaws here are irreversible and will be evident later on the product. The quality of the finish is, therefore, essential to the market success.

For cold rolling and surface treatment, Balluff provides high precision: quality products for best performance even in the final stretch – at the dancer roll, winder, coating system or quality control.

Downloads

-

Industry brochure steel and metallurgical industry