Magnetic field sensors

Contactless and reliable position feedback

Magnetic field sensors are used chiefly for punctual or continuous monitoring of the piston position on cylinders and grippers. The sensor thus recognizes the field of the magnet integrated into the piston through the actuator wall.

With their contactless position detection, Balluff's magnetic field sensors function reliably and wear free: No contact erosion, no bounce and only clean measurement. Even at high movement speeds, the piston position is reliably recognized.

Product guide for object recognition

Tell us what your requirements are and we will tell you which product you need!

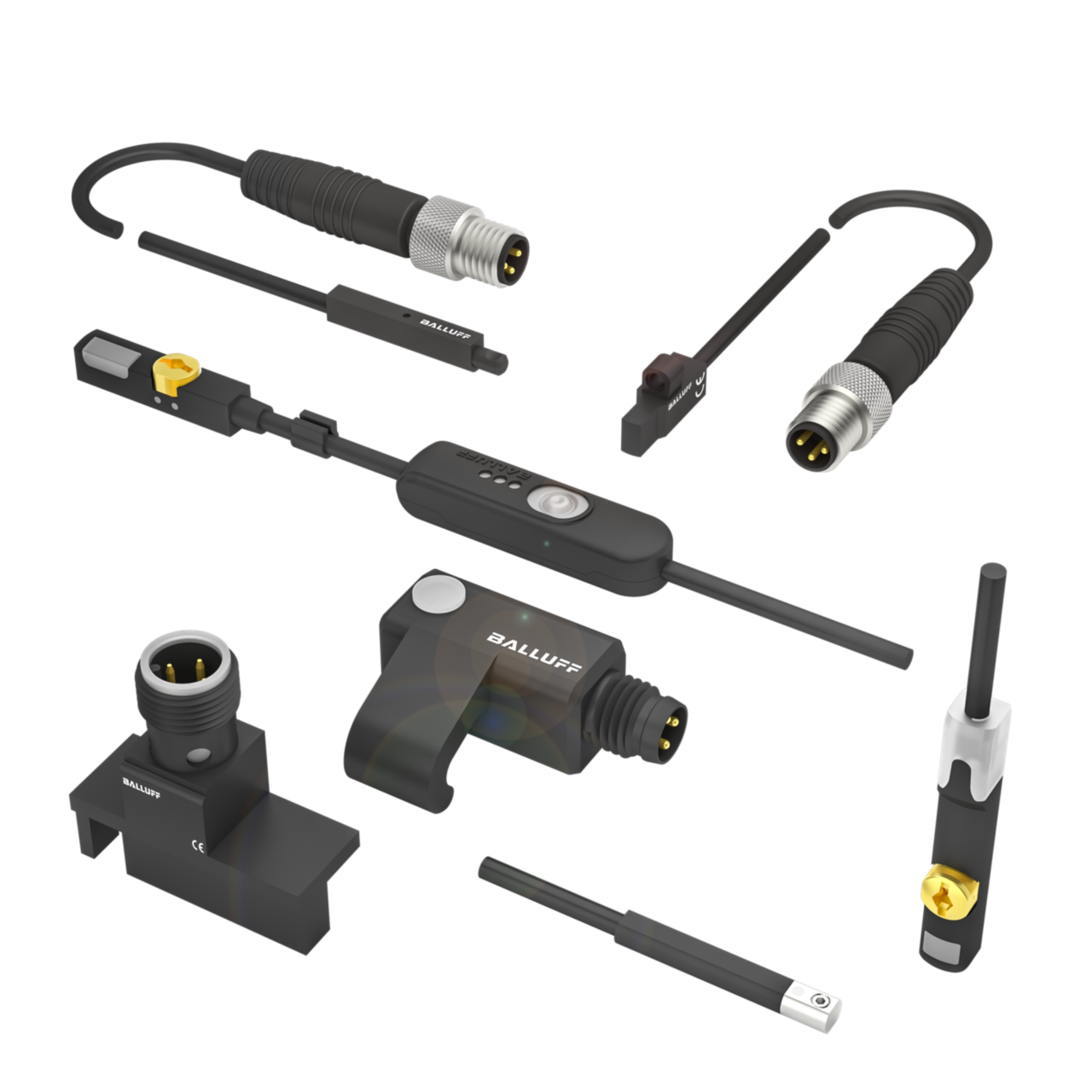

Cylinder sensors for multiple slot shapes

Single-connector version with two BMF magnetic field sensors

Cylindrical magnetic field sensors

Magnetic field sensors with adjustable switchpoints