Connecting and Networking

From direct connection to intelligent fieldbus and non-contact transmission systems

Communication in machines and industrial systems is becoming ever more essential in automation technology. Sensors generate information that needs to be transported wherever it is processed. We will show you how cable, distributors and entire networks enable this transport. Important to know: Sensor connectivity is undergoing a change from directly wiring through junction blocks to intelligent fieldbus and non-contact transmission systems.

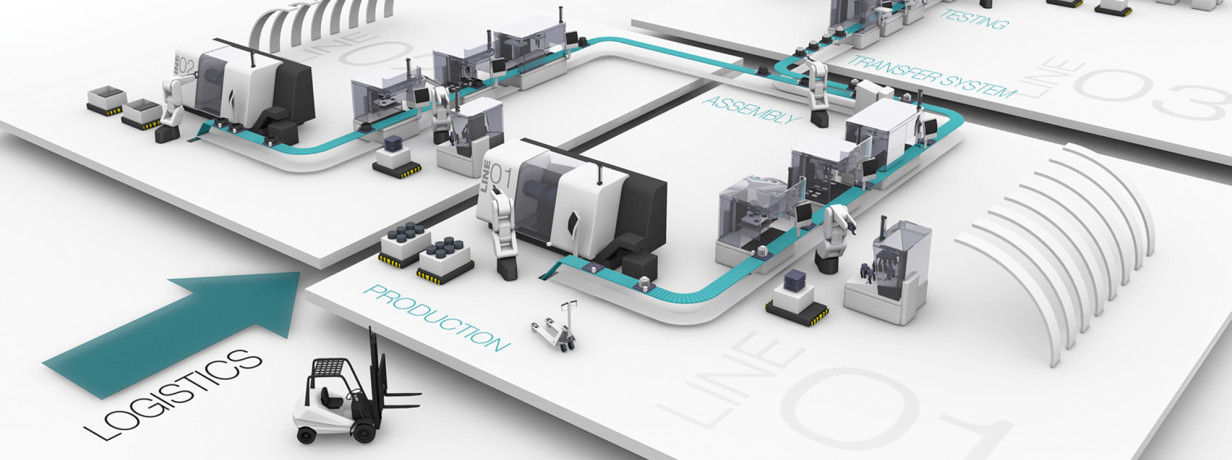

An industrial system consists of various machine types which are required for manufacturing a product. In each machine type you will find different sensors which transmit their signals to the controller (PLC). The controller uses the signals to initiate the appropriate work steps. This communication can take place in three different ways:

Each individual sensor is wired directly to the PLC

Multiple sensors are wired to the PLC through a junction blocks

The sensors are connected to the PLC through fieldbus block

Connectivity and network technology

Over the years, the method of wiring and cabling has radically improved: Sensors have traditionally been directly wired to the PLC using a sensor cable. To reduce effort and expense, junction blocks are used which collect and consolidate the signals from multiple sensors on their way to the PLC. Intelligent fieldbus blocks handle the collection and transmission of the signals to the PLC over entire networks. In addition there are non-contact transmission systems which pass signals and power in especially critical applications.