- Matrix Vision solutions now all under the Balluff brand

- IO-Link: Intelligent solutions for modern automation

- Smart Automation and Monitoring System

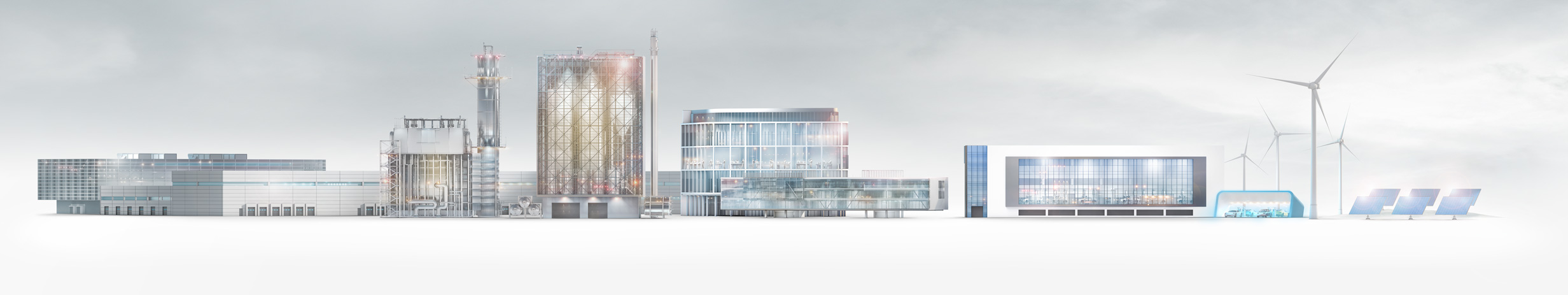

- Architects of Smart Manufacturing

- Comprehensive components and solutions for automated welding

- Level Detection

- Explosion Protection

- Quality Assurance

- High Durability

- Miniaturization

- MicroSPOT

- Condition Monitoring

IO-Link: Intelligent solutions for modern automation

Improved process quality with IO-Link

With IO-Link, you can rely on a future-proof communication solution that takes your automation to a new level.

Balluff offers IO-Link-capable products that have been specially developed to optimize industrial processes and take data communication to a new level. With one of the largest IO-Link portfolios, Balluff develops the right solution for your requirements.

Our range includes sensors with different functional principles as well as a broad spectrum of network and connection technology. Balluff thus supports all common fieldbus protocols with fieldbus systems such as Profibus, Profinet, Ethernet-IP, Devicenet, CC-Link and EtherCAT, we speak IO-Link in all areas. Our product range also includes the latest, future-proof technologies such as IO-Link Wireless and IO-Link Safety.

IO-Link masters and hubs: central interfaces for efficient communication

Balluff offers IO-Link master modules that connect intelligent sensors and actuators to the controller. We offer industry-leading portfolio of sensor and actuator hubs for connecting digital and analog devices. Your benefits with our IO-Link masters:

Multi-protocol with autodetect capability: Support for protocols such as PROFINET, EtherNet/IP and EtherCAT, so that they can be integrated into almost any control environment.

Web interface: Simpler configuration and management via user-friendly interfaces, making implementation much easier.

Integrated power monitoring:Monitor energy consumption in real time to identify potential energy savings.

IO-Link sensors: Precise data acquisition and extended diagnostic options

Our portfolio includes sensors with different functional principles that can be perfectly integrated into IO-Link systems:

Inductive sensors: Ideal for contactless detection of metal objects. IO-Link enables switching distances to be set precisely and diagnostic data such as temperature or wear limits to be read out.

Capacitive sensors: Perfect for detecting fill levels or the presence of non-metals. Sensitivity and switching behavior can be optimally configured via IO-Link.

Optoelectronic sensors: With IO-Link, the sensors transmit not only the switching status but also additional information such as signal strength or fault diagnostics, which increases system availability.

IO-Link in RFID: Intelligent identification and data acquisition

The combination of IO-Link and RFID technology is a powerful solution for optimizing industrial processes. RFID enables the contactless identification and tracking of objects, which increases efficiency in production and logistics. As a standardized interface, IO-Link simplifies communication between the RFID system and the control level. Overall, the integration of RFID with IO-Link leads to a significant increase in automation, transparency and efficiency in industrial automation.

Vision sensors with IO-Link: Precise optical inspection and reliable data transmission

IO-Link simplifies the installation and use of vision and identification sensors in industrial image processing through standardized networking, central parameterization and simple integration. The reliable transmission of process and diagnostic data facilitates maintenance and monitoring - even in complex automation systems. The bidirectional communication between sensor and IO-Link interface enables the use of intelligent functions such as condition monitoring data.

The combination of intelligent sensor technology and IO-Link creates a flexible and efficient solution that meets the increasing demands for maximum quality and great flexibility in modern manufacturing and logistics environments.

IO-Link advantages

Benefit from fast installation, simple parameterization and continuous diagnostics - for maximum flexibility and reduced operating costs.Software and cloud solutions for IO-Link: Simpler, faster, smarter

Applications: The versatile use of IO-Link in industry

IO-Link is used in numerous industries and applications to make automation processes more efficient, transparent and flexible. The technology is used in particular in manufacturing technology, logistics, the food and beverage industry and the automotive industry. In production lines, IO-Link enables precise recording and transmission of sensor data in real time. In condition monitoring, IO-Link sensors provide continuous information to predict maintenance intervals and prevent failures.

IO-Link also plays a central role in robotics, as the wireless IO-Link technology increases the freedom of movement of robots and facilitates installation in areas that are difficult to access.

Thanks to the ability to transfer IO-Link data to cloud systems, global production data can be evaluated centrally and used to optimize processes. IO-Link thus creates the basis for smart factory concepts and supports companies on their way to Industry 4.0.