12.04.2024

Balluff adds features to code reader with IO-Link

Optical code reader with firmware update an easy choice to replace legacy cameras, code readers

A firmware update delivers next-level capabilities to Balluff’s code reader with IO-Link.

The updates add many requested features, including:

Control of digital outputs – This allows you to trigger the code reader with a direct input (a photoeye, for example) and to fire an output for read/no read/code mismatch, etc. This feature was highly requested and allows the IDENT Sensor to easily replace legacy cameras and laser-based barcode readers.

Total sensor backup and teach button lock-out

Multiple code tool — This is an especially helpful addition for applications requiring multiple barcodes/2D codes.

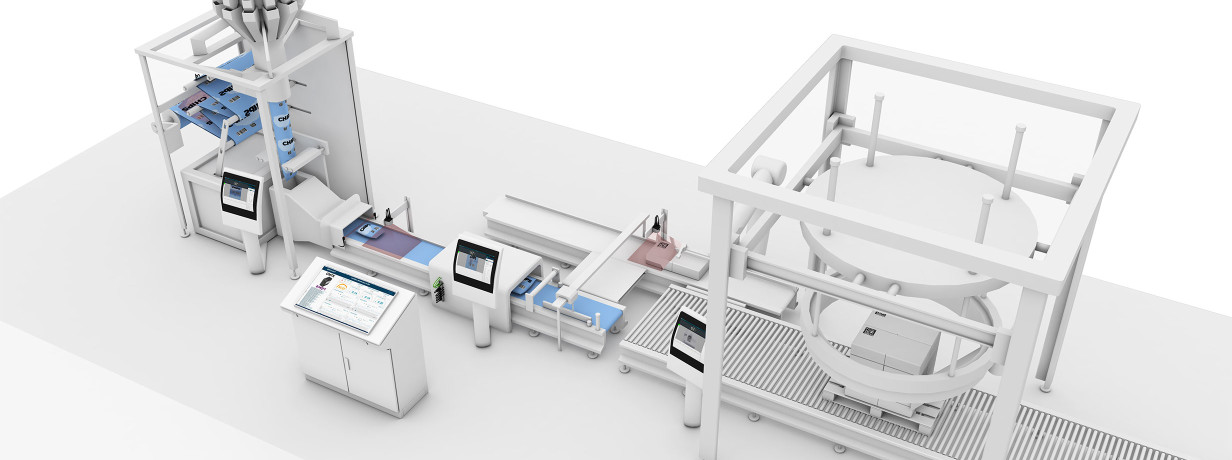

Introduced in 2023, the IDENT sensors read 1D and 2D barcodes and direct part marked codes while providing several other innovative features, including built-in condition monitoring capabilities. The inclusion of IO-Link allows users to integrate code reading without adding separate Ethernet drops and IP addresses for every reader.

In addition to code reading functions, the sensors can provide visibility into the machine and/or application environment. They can monitor internal temperature, vibration, humidity, inclination, signal quality and operating time — data that can save operators time and money by minimizing downtime and increasing maintenance efficiency. Condition data is transmitted every 60 seconds. Operators can view the data via a dashboard using a web browser. No added software is needed.

These stationary sensors use the MVTec HALCON algorithm, with integrated code quality metrics that allow it to provide a code quality grade in addition to the code data. Users can select from multiple process and data interfaces to meet their needs with support for the REST API and MQTT and IO-Link and TCP/UDP interfaces.

Fast reading speeds and a working distance of 50 to 600 mm make the IDENT sensors a solid choice for production processes and logistics applications across a wide range of industries, with an IP67 rating which makes them a good choice for packaging, food, and beverage applications as well. It offers electrical certification for most areas: cULus, CE, UKCA, FCC and WEEE. Versions are available with white and red light or white and infrared light. A standard M12 connection and a teach button make for easy setup.

The firmware update for this vision-based code reader helps it deliver next-level capabilities for the future of manufacturing.

Firmware features

Backup / Restore of product settings and inspection programs

Multi-User login locally and remotely

Multiple code tool in an inspection program

Configuration of digital inputs and outputs on power or IO / light connector

Blocking of teach button