02.08.2021

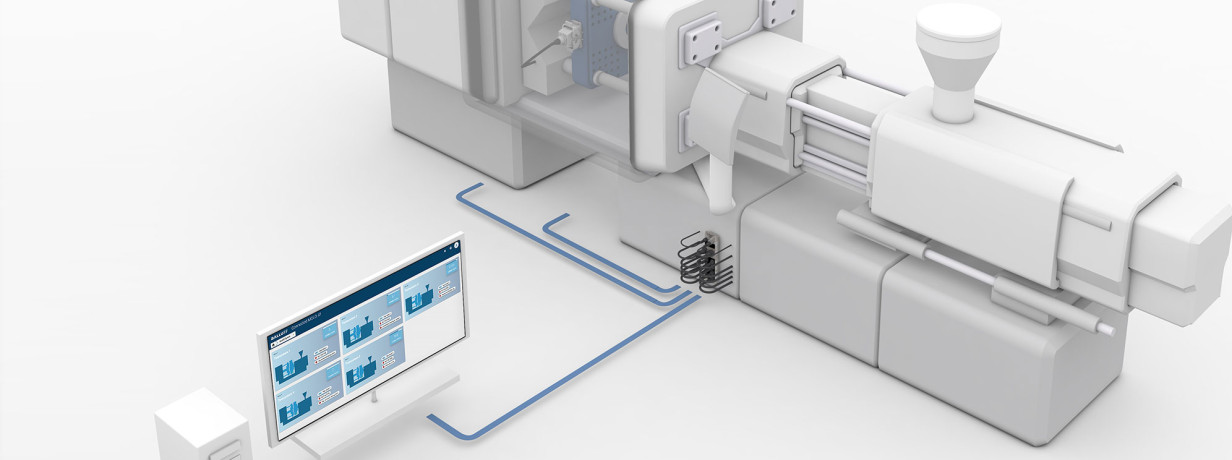

Plug-and-Play Solution for Tool Data Management Optimizes Mold Use, Reduces Downtime

Balluff’s Connected Mold-ID system provides tool status, history and production cycles

Balluff offers a simple plug-and-play solution to record and manage injection mold data. Using RFID, our new digital tool management system, Connected Mold-ID, provides tool data including details of the tool’s history, production cycles, and current status of the individual Mold-ID systems.

The autonomous system optimizes use of the molds while preventing mold failures and reducing unplanned downtime. The inspection intervals are always visible. Users are informed of each tool deployment and can be ready with format changes when needed. All data is stored directly on the tool via the RFID data carrier as well as in the software. The software is accessible through any modern web browser.

“Connected Mold-ID is an extension of standard Mold-ID. It is the handling of the big data collected by a standard Mold-IS system. It allows the user to visual that data and turn it into actionable data,” said Wolfgang Kratzenberg. “This is a stand-along tracking system that optimizes the use of what they are already doing.”

Human error related to manual management of mold data can lead to interrupted production processes and information gaps. Connected Mold-ID meets the demand for fast process control and simple management. Connected Mold-ID increases the flexibility and efficiency of your production and provides transparency into the process – all factors of intelligent manufacturing and requirements of IIoT.

Key features

Low-cost and simple entry into digital tool management

Documentation of the tool life cycle and recording of production cycles through an autonomous system

Instead of loss of information, high data security: all data available directly on the mold and in the database, accessed via standard web browser

Optimal mold changes by visualization of inspection intervals on the system and in the software

Efficient mold management - continuous process monitoring and planning, an overview of the entire mold inventory, mold details and machinery in browser application

Networking of all Mold-ID systems and recording of injection mold data in central database on internal server (on-premise solution)

- [email protected]

- 1-800-543-8390

-

8125 Holton Drive

Florence, KY 41042

Products

Products