Product Identification with Industrial RFID

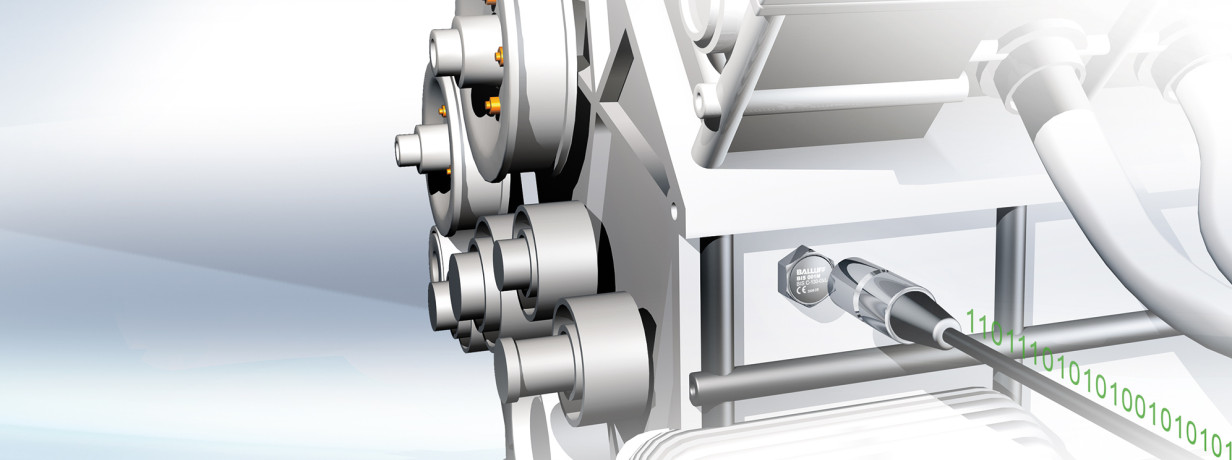

Reliably track parts with Industrial RFID

In addition to tool identification, Industrial RFID systems from Balluff also offer significant advantages in unbroken documentation and automation of the entire manufacturing process.

Parts can easily be traced in the machining process or assembly process. This is because every processing or assembly step is recorded on the data carrier. This is the only way that maximum process reliability and quality can be guaranteed through traceability.

In addition, you can precisely monitor work steps that directly precede or follow the production process, and use them for optimized resource management. With Industrial RFID from Balluff you can create transparency and reduce your costs.

These products help you achieve unbroken documentation

Related topics

Downloads

-

Tool Identification and Workpiece Tracking

-

Overall Product Catalog 2019

Products

Products