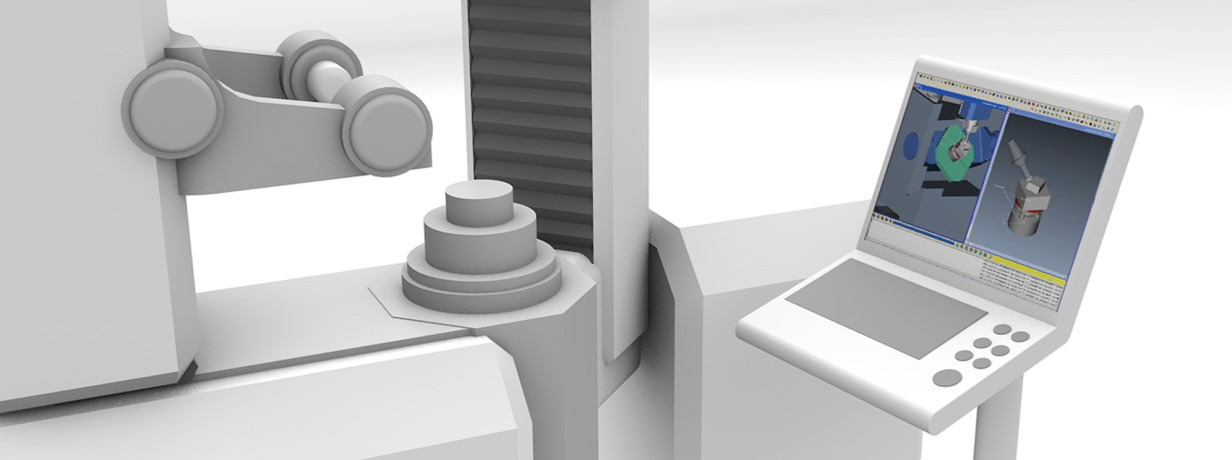

Tool identification with Industrial RFID

Save all relevant tool data and access it at any time

Industrial RFID systems from Balluff provide you with the analysis data that is indispensable for exact cost calculations and modern quality and tool management.

All relevant tool data, such as numbers, dimensions or service life, are saved reliably. And are always available. Tool management supported by Industrial RFID thereby simplifies data management, improves the quality of the production process and increases efficiency. Robust and insensitive to environmental influences, our powerful Industrial RFID systems are extremely reliable and functionally safe, particularly in the rough industrial conditions of machine tools. This is guaranteed by their inductive principle of operation.

In order to satisfy your requirements on an individual basis, various data carriers, read/write heads, processor units and accessories are available to you. Make your choice based on the features you need. And you will benefit from the easy integration of the systems.

How you benefit

Tool management with Industrial RFID provides a staggering number of advantages over conventional tool handling without Industrial RFID.

The features

Greater machine uptime

Greater cost-effectiveness

Convenient and absolutely reliable storing of tool data

Simple integration into the tool

Ready to use immediately

1. Machine tool

Thanks to reliable, clear assignment in the tool magazine, you benefit from greater machine availability. All tool data is acquired and automatically transferred to the machine memory. Data is thus never entered incorrectly or entirely forgotten.

2. Service life control

Exact inventorying reduces stock level requirements and offers great savings potential. The accurate tracking of the tools in the working process ensures the most efficient use of tools. You will benefit from maximum quality because tools will be reground or exchanged just in time. All of this increases your profitability.

3. Tool measurement

Securing tool data is convenient and absolutely reliable. All the data is stored without contact on a data carrier embedded directly into the tool holder. No more manual entry errors. The tool data is permanently and uniquely associated with the tool.

4. New tool

We offer attachment holders for all common tool holders.

5. Tool storage

The tools are always at the ready. This allows them to be utilized optimally. The saved data is complete, error-free and can be accessed at any time.

Related topics

Downloads

-

Tool Identification and Workpiece Tracking

-

Overall Product Catalog 2019

Products

Products