Intelligence included

Precise positioning for cranes

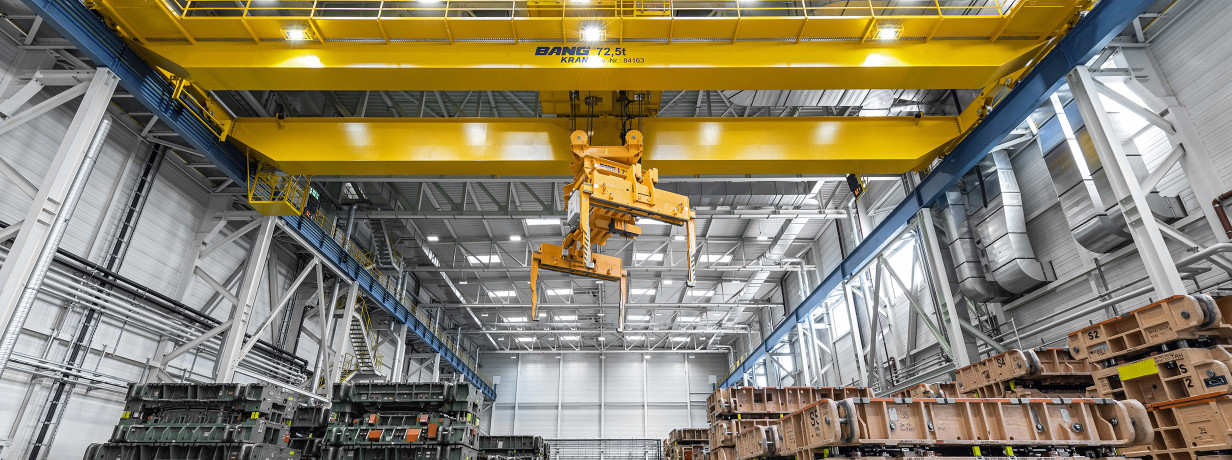

Industry:Warehousing cranes |Customer:Bang Kransysteme GmbH & Co. KG

Bang manufactures process and tool transport cranes for loads up to 500 tons for the automotive, steel and energy industries. When customers demand the highest levels of reliability, positioning accuracy and freedom from interference from their semi or fully automated handling and intralogistics systems, the crane specialist relies on sensor systems from Balluff.

Situation

Especially with cranes in intralogistics, the operator and the control system must always reliably know the absolute position of the crane. Especially when two or more cranes are in motion on one track.

If the degree of contamination in a hall is high or if the cranes are operated outdoors, optical systems reach their limits.

Challenge

The task was to find a system that was absolutely reliable and could be integrated into existing systems without major assembly and maintenance effort.

In addition, the system must be able to move to positions with repeatable accuracy to the millimeter and thus enable safe autonomous control.

Solution

It is precisely for such cranes and wherever maximum precision is required for position and speed measurement over long distances that Balluff offers an absolute measuring displacement encoder system. With the LDPS system, positions up to 1500 meters away can be determined with a repeatability of +- 0.5 mm.

The Long-Distance-Positioning-System operates wear- and maintenance-free and is insensitive to shock, vibration and contamination. All it needs is a sensor traveling on the crane and statically mounted magnets on the travel path.

With this technology, Bang is now able to operate the crane completely autonomously. The exact position data in the control system means that expensive collisions can be avoided. Information, such as blocked areas or articles, can now also be safely integrated into the process.

How does it work?

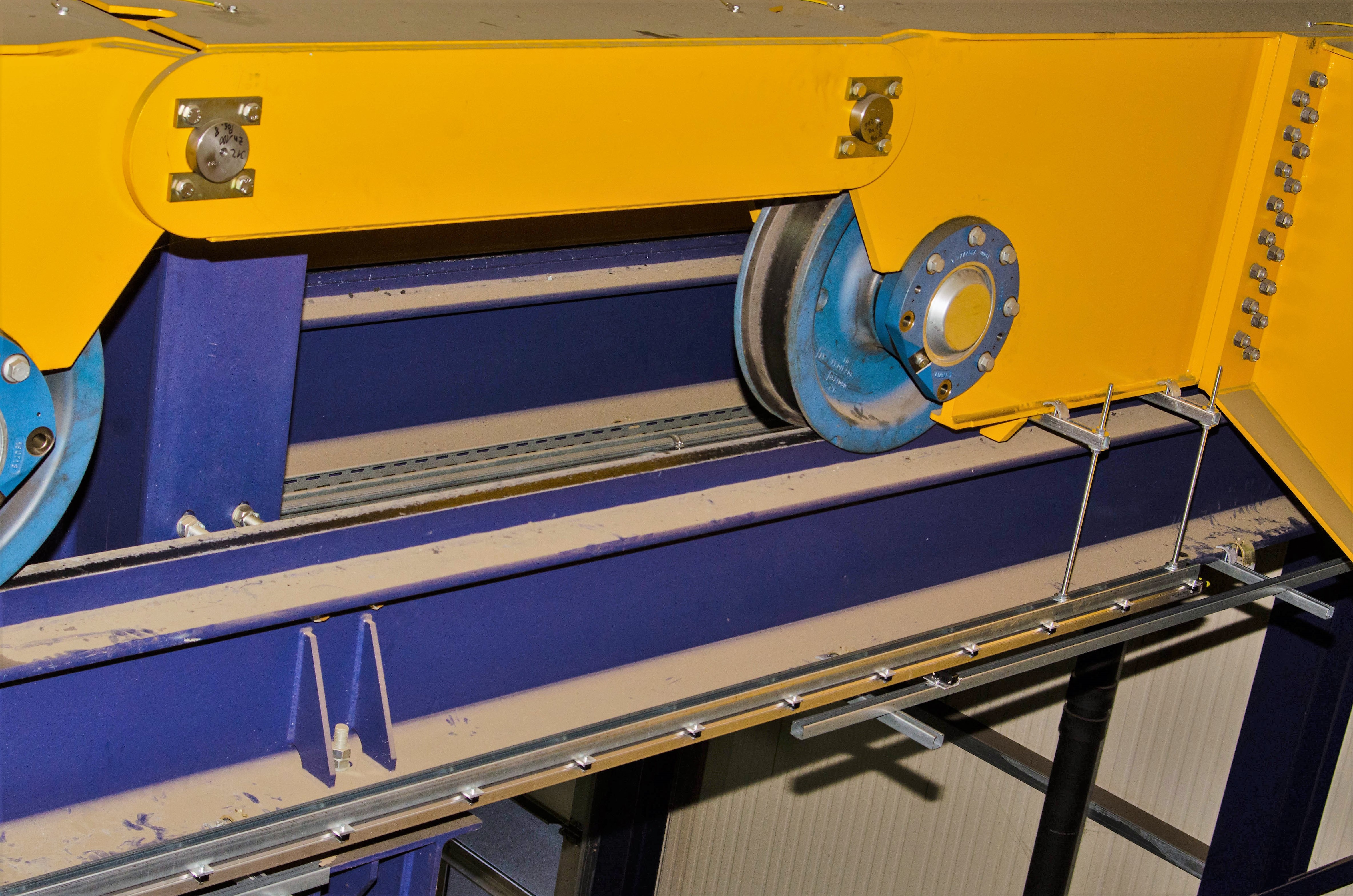

To use this rugged and robust IP67-system, the magnets are mounted on the fixed rail underneath the moving crane. The sensor is mounted on the moving crane and travels over the magnets. In this way the system is completely wear-free and independent from light and dust.

The distances from the fixed magnets to the moving sensor are between maximum 15 mm and 56 mm.

What is special about that system is that you don't need to mount the magnets very precisely to get a perfect result. The position of the magnets will be calibratet automatically within the included function block for Siemens TiA. No need for you to program it by yourself. You will get the complete solution, tailored to your needs.

The position measuring system, which travels with the crane and is approx. 4 m long, detects the position sensors that are mounted along the travel path according to a predefined pattern and calculates the absolute crane position from them.

If the knowledge of this position is indispensable, even under adverse even under adverse conditions, the Long Distance Positioning System is ideally suited.

Benefits

- LDPS enables you to fully automate your warehouse

- LDPS will save you money because of effective ways

- LDPS will avoid manual mistakes and collisions

- LDPS is wearfree and easy to install

- LDPS is ideal for retrofitting your machine

Products

Our Long Distance Positioning System is avaible as "LDPS - up to 250 m" and as "X-LDPS - up to 1500 m".