No errors during guided format change

Get it done faster, cheaper and safer with the GCS

Industry:Food and Beverage IndustryCustomer:Global Leader in Food Manufacturig

A global leader in food manufacturing had a specific need to improve production efficiency. After evaluating and piloting they decided to implement the Balluff "Guided Changeover Solution" on a coffee can labeling machine.

Situation

The machine handles five different can sizes ranging from the smallest at 400 g to the largest at 1700 g. The substantial size variations make changing formats challenging, especially when moving between the smaller and larger can sizes.

This particular production line has a high commercial demand and requires operating 24 hours a day. The machine with its twelve change points had become a bottleneck during changeover process, making it vital to reduce downtime in order to produce the required demand.

Challenge

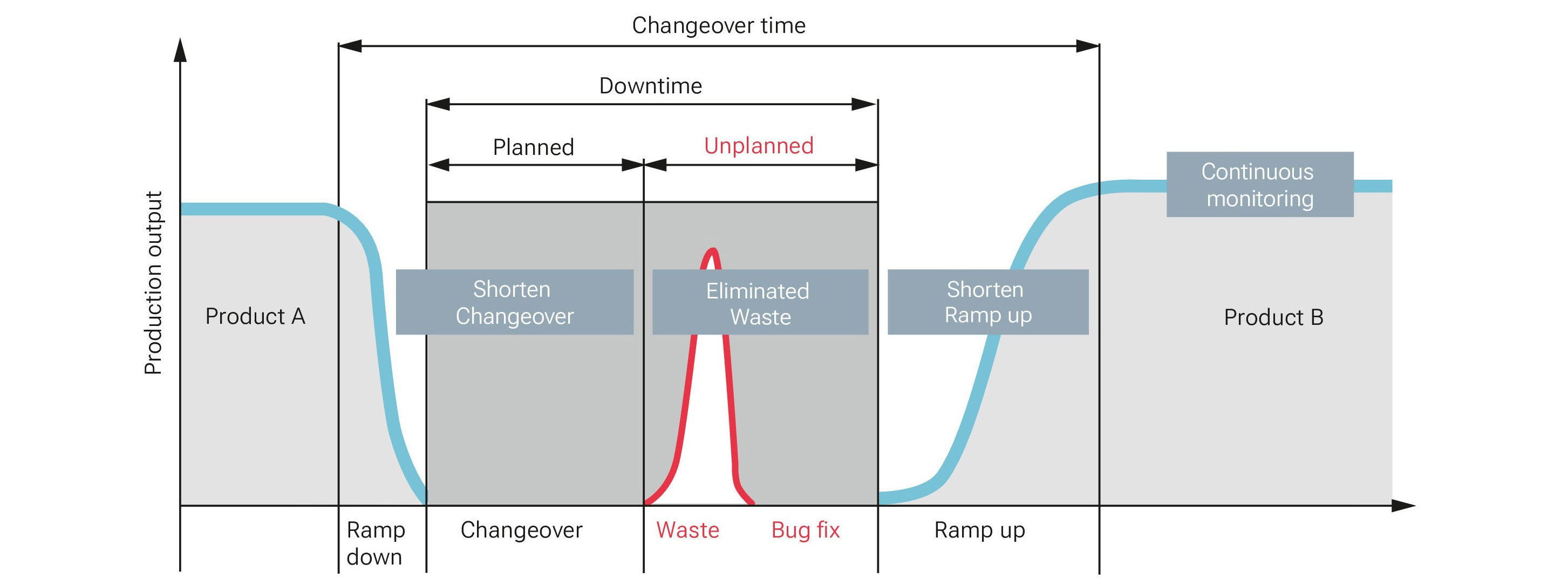

The main challenge was to reduce format change downtime and improve ramp up of the production line after a completion of changeover. Every minute that is saved here can be used for more valuable production. It was also important to reduce training requirements and the need for experienced personnel. Good and skilled people are hard to find and also more expensive.

The overall challenge was to increase the productivity and profitability of this production line to produce more goods for less money.

Solution

The machine handles five different can sizes ranging from the smallest at 400 g to the largest at 1700 g. The substantial size variations make changing formats challenging, especially when moving between the smaller and larger can sizes. This particular production line has a high commercial demand and requires operating 24 hours a day. The machine with its twelve change points had become a bottleneck during changeover process, making it vital to reduce downtime in order to produce the required demand.

It only required three steps for the customer to realize the full benefit of the Guided Changeover Solution retrofit:

Identify the changeover points or centerlines

select and install the appropriate sensors

create step-by-step instructions for the operators in the Guided Changeover Solution software

How does it work?

The Guided Changeover Solution software guides them step by step through the format change process. Sensors provide immediate feedback about the change point positions and thus facilitate, accelerate and verify the correct settings of lengths, heights and widths.

With these instructions and the verification of the sensors, the required changeover time is now documented and consistent and not dependent on individual experience.

Every change point is set correctly, fine tuning (tweaking) so no longer necessary. This not only significantly reduces the time for format changes, but also makes the ramp-up much faster. At the same time mistakes are avoided and less waste is produced.

The labeler in question is an older model from the 1980s, with limited automation capabilities. However, as the "Guided Changeover Solution" is a standalone solution that does not disrupt the original machine controls, it was easily retro-fitted, effectively extending the lifespan of the machine with minimal investment.

We feel very comfortable with the solution and our operators have adapted well to it. The solution reduced the format change time from 80 minutes to 40 minutes. This was achieved through adequate training and coordination with Balluff. We will start implementing the solution in the next machine.

Benefits

You should use the Guided-Changeover-solution in your application because:

- The system is easy to use - by everybody. No experience needed.

- All manual changeover processes can be retrofitted with it.

- No mistakes possible - adjust and produce.

- Produce less waste in the ramp up - save money and our planet.

Products

Everything the global Leader in Food and Beverage production needed was the guided-Changeover-Solution-Software and the Sensors to measurer distances and part presence. Find all used sensors here:

Network blocks for Profinet

- Special characteristics

-

Washdown Plus

Washdown - Interface

- Profinet

- Interface IIoT

- REST API

- Auxiliary interfaces

- 8x IO-Link

- Port-class

- Type A

- Output current max.

- 4 A

- Fast Start-Up (FSU)

- yes

- Operating voltage Ub

- 18...30.2 VDC

- Connection (COM 1)

- M12x1-Female, 4-pin, D-coded

- Connection (COM 2)

- M12x1-Female, 4-pin, D-coded

- Connection (supply voltage IN)

- M12x1-Male, 5-pin, L-coded

- Connection (supply voltage OUT)

- M12x1-Female, 5-pin, L-coded

- Connection slots

- 8x M12x1-Female, 5-pin, A-coded

- Digital inputs

- 16x PNP, Type 3

- Digital outputs

- 16x PNP

- Configurable inputs/outputs

- yes

- Current sum US, sensor

- 16 A

- Current sum UA, actuator

- 16 A

- Housing material

-

Plastic

Stainless steel - Dimension

- 68 x 36.8 x 226 mm

- Ambient temperature

- -25...70 °C

- IP rating

-

IP68

IP69K - IO-Link version

- 1.1

- Safety Hub Support

- yes

- Secondary features

-

Operating Hours Counter

Voltage and Current Monitoring

Boot Cycle Counter - Secondary features for condition monitoring

- Internal temperature monitoring

Photoelectric distance sensors

- Series

- 21M

- Dimension

- 15 x 51 x 42.5 mm

- Interface

-

IO-Link: 1.1

Analog, current: 4…20 mA

linear rising/falling

2x PNP/NPN: NO/NC - Principle of operation

- Photoelectric distance sensor

- Principle of optical operation

- Triangulation

- Beam characteristic

- Focus, typical at 400 mm

- Light type

- Laser red light

- Light spot size

- 1.5 x 0.5 mm at 200 mm

- Range

- 30...200 mm, adjustable

- Accuracy

-

±1 mm max. (30...170 mm)

±3 mm max. (170...200 mm) - Repeat accuracy

- ≤ ± 0.25 mm

- Resolution

- ≤ 10 µm typ. (30...170 mm) 100 µm typ. (170...200 mm)

- Connection

- Connector, M12x1-Male, 4-pin

- Housing material

-

Zinc, Die casting, Painted

Aluminium, Glass, PMMA, black - Operating voltage Ub

- 15...30 VDC

- Approval/Conformity

-

CE

UKCA

cULus

IO-Link

WEEE

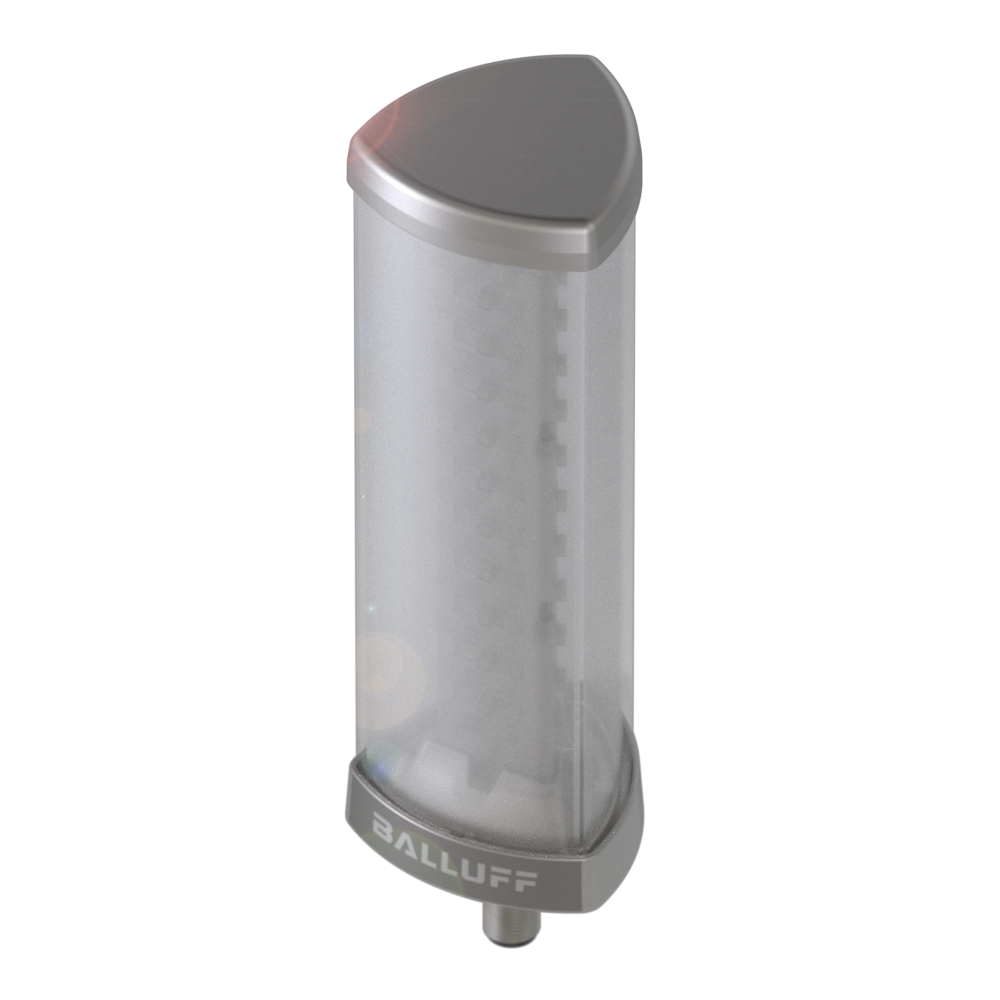

SmartLight - LED stack lights

- Principle of operation

- Indicator light

- Interface

- IO-Link 1.1

- Operating voltage Ub

- 18...30.2 VDC

- Connection

- M12x1-Male, 4-pin

- Segments, number max.

- 3

- Predefined colors

-

yellow

white

green

Blue

red

orange

configurable - Function indicator

-

Runlight Mode

Level Mode

Segment Mode

Flexi-Mode - Setting

- Function indicator

- Additional function

- Expanded process data

- Dimension

- 60 x 60 x 213 mm

- Housing material

-

PC, Transparent, Cu 15 µm, Ni 15 µm

Die-cast zinc - Mounting part

- Screws M18

- Ambient temperature

- -5...50 °C

- IP rating

- IP65

- Transfer rate

- COM2 (38.4 kBaud)

- Process data cycle min.

- 7.2 ms

- Process data IN

- 1 byte

- Process data OUT

- 8 bytes

Inductive position sensors

- Dimension

- 149.5 x 21 x 22 mm

- Style Housing

- block style

- Connection

- Connector, M8x1-Male, 4-pin

- Housing material

- PBT

- Measuring range

- 0...133 mm

- Interface

- IO-Link 1.1

- Repeat accuracy per BWN

- ±80 µm

- Non-linearity max.

- ±400 µm

- Operating voltage Ub

- 18...30 VDC

- Ambient temperature

- -25...85 °C

- IP rating

- IP67

- Approval/Conformity

-

CE

UKCA

cURus

WEEE

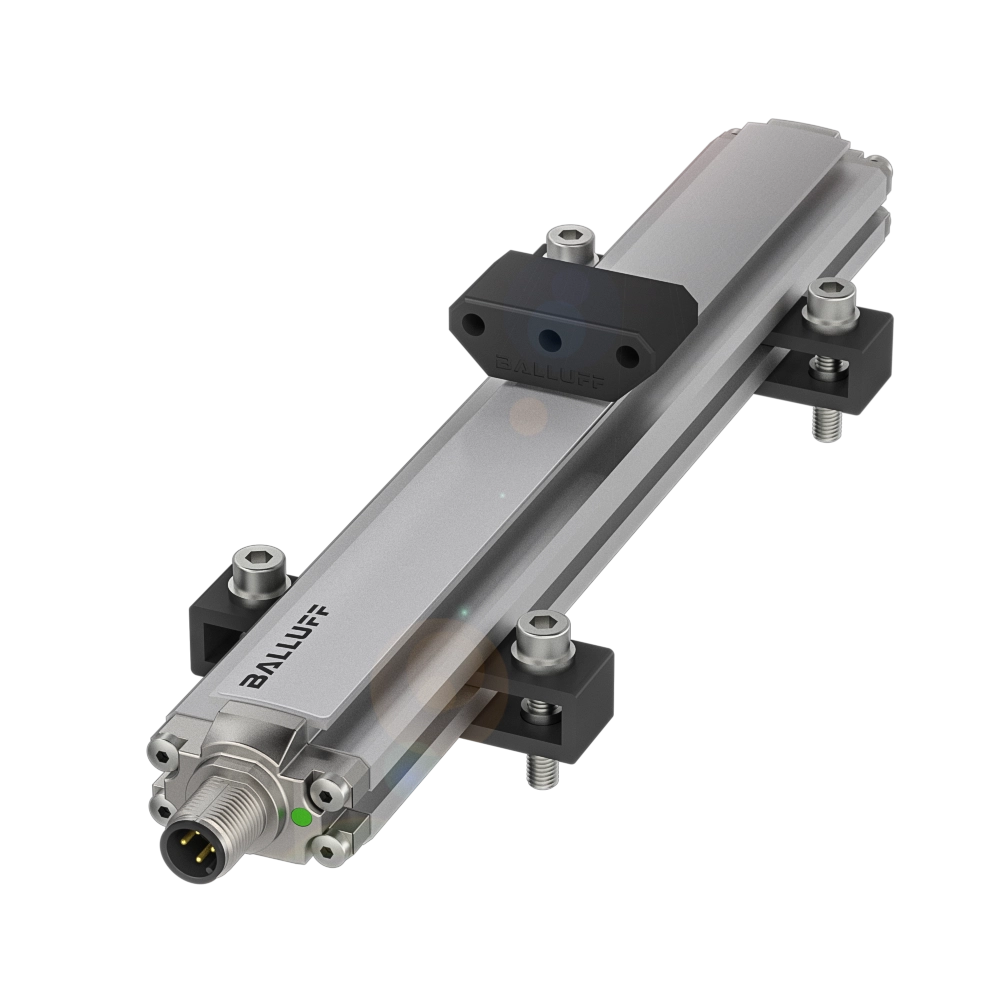

Magnetostrictive linear position sensors in profile housing

- Interface

- IO-Link

- Measuring length

- 25...4000 mm

- Repeat accuracy

- ≤ ± 10 µm

- Linearity deviation

- ± 50 µm

- Operating voltage Ub

- 18...30 VDC

- Ambient temperature

- -25...85 °C

- Mechanical configuration

- Flat profile - 21 x 35 mm

- Housing material

- Aluminium, Anodized

- IP rating

- IP67 with connector

- Approval/Conformity

-

CE

UKCA

cULus

WEEE