IO-Link vs. IO-Link Wireless: Enhancing Flexibility and Efficiency in Automation

From Wired to Wireless: Exploring the Evolution of IO-Link Technology

Reading Time: minutes

Industrial automation relies heavily on efficient communication protocols to ensure seamless data exchange and control between devices. Among the plethora of protocols available there is one fast growing and prominent contender: IO-Link.

IO-Link was introduced to simplify and enhance the integration and management of devices. Unlike traditional point-to-point communication, IO-Link offers bidirectional communication, enabling more detailed data exchange, diagnostics, and configuration capabilities. This allows for improved process efficiency, predictive maintenance, and easier device replacement. By using IO-Link, industries can achieve higher levels of automation, reduce downtime, and optimize production processes.

Since its introduction in 2006, IO-Link has continuously evolved, not only in terms of the available components and market penetration but also technologically. There is now a wireless variant of the IO-Link protocol, known as IO-Link Wireless. Both variants, Standard IO-Link and IO-Link Wireless, will be examined in more detail in this article.

Understanding Standard IO-Link

Standard IO-Link stands as a cornerstone in industrial automation, providing reliable point-to-point communication between sensors, actuators, and controllers.

But why choose IO-Link?

Let’s take a closer look at the advantages and disadvantages.

Pros

-

Device Versatility: IO-Link offers compatibility with a wide range of devices, from simple sensors to complex valve manifolds, providing unparalleled flexibility in system design.

-

Enhanced Diagnostics: Its communication protocol provides detailed diagnostic feedback, facilitating predictive maintenance and minimising downtime by quickly identifying potential problems.

-

Remote Configurability: Standard IO-Link allows devices to be remotely parameterised and configured, streamlining setup processes and enabling rapid reconfiguration for different operational requirements.

-

Easy Device Replacement: Standardised interfaces ensure that devices can be swapped with minimal disruption to the system.

-

Connecting not Wiring: This point deserves special mention. IO-Link has revolutionised wiring. Instead of the traditional labour intensive method of terminating individual wire connections, IO-Link devices can simply be connected to each other using standard sensor cables. This not only saves time, but also reduces the risk of wiring errors and greatly simplifies installation.

Cons

-

Wired Connectivity: Although IO-Link only requires standard sensor cables, the fact that it uses cables can also be mentioned as a disadvantage.

-

Limited Range: Due to its wired nature, standard IO-Link has a limited range, typically up to 20 meters, which can be a challenge in large industrial environments. Additional modules are required to extend the range.

-

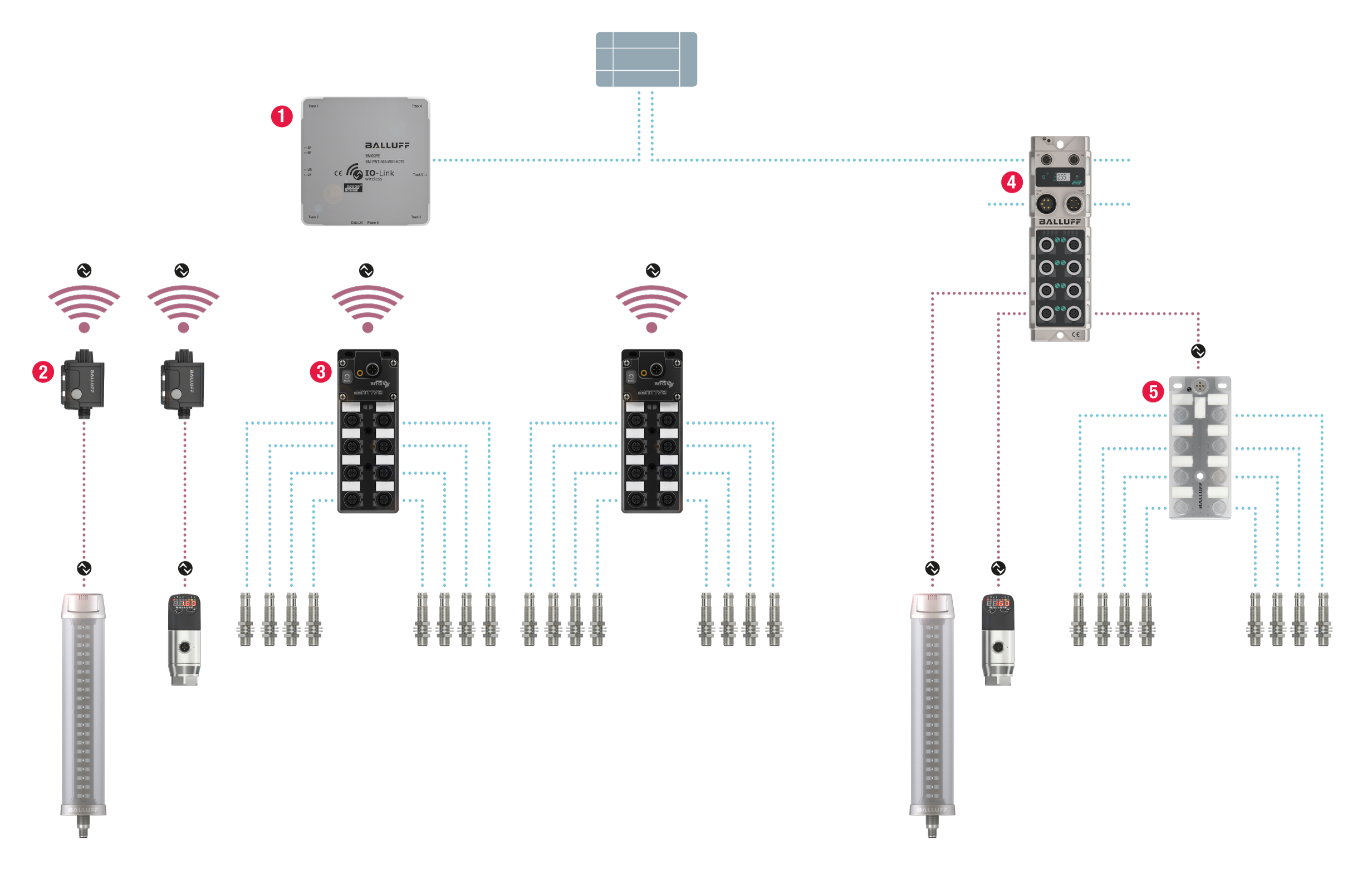

Typical Architecture of Standard IO-Link: The architecture of a Standard IO-Link system typically comprises sensors and actuators equipped with IO-Link interfaces, connected via IO-Link master modules to the industrial controller. This hierarchical structure facilitates seamless data exchange and control between devices and the central controller, as illustrated below.

Application Example for Standard IO-Link

Application examples for Standard IO-Link can be found almost everywhere. Every production line needs to transport information between sensors and the PLC; otherwise, automation would not be possible. Despite the numerous applications for IO-Link, some scenarios particularly highlight the superior benefits of this protocol over other communication methods.

One prime example is a machine with a high number of sensor inputs or outputs. In such cases, IO-Link proves to be a real time-saver with its ability to directly connect sensors to the IO-Link Master without the need for extensive electrical cabinets or terminal blocks. This streamlined connection not only simplifies the installation process but also significantly reduces wiring complexity. Additionally, IO-Link facilitates the seamless integration of new devices and ensures consistent communication standards across the production line.

Furthermore, the programming, configuration, and maintenance of the machine become considerably easier. The IO-Link system allows for rapid and precise diagnostics, enabling quicker troubleshooting and minimising downtime. Its capability for remote configuration and monitoring ensures that any changes or updates can be implemented swiftly without halting production. This efficiency in setup and maintenance demonstrates the substantial advantages of IO-Link in complex automation environments, making it an indispensable tool for modern industrial processes.

Related topics

Keywords

- IO-Link

- Industrial automation

- Innovations

Author

Balluff EMEA

We are your partner for innovative solutions in industrial automation. With our passion we improve your competitive position with speed and results. With our 100 years company history and more than 60 years of sensor experience, Balluff is a world leader and one of the most efficient manufacturers of sensor technology.

4 Contributions

Comment

Popular posts

What is a capacitive sensor?

How do I wire my 3-wire sensors?

Industrial sensing fundamentals – NPN vs PNP

The industrial revolution - from the steam engine to Industry 4.0

Contact form

Do you have any questions or suggestions? We are at your disposal.

Balluff Limited

-

20 Cheshire Business Park

Cheshire Avenue

Lostock Gralam

Northwich, CW9 7UA