Identifying – Work-in-Progress

Using RFID to monitor production in automated assembly

It is important that in an assembly process you are always able to track vendor and lot information for all the installed components.

When the need is for highly flexible production on a line consisting of various product versions, RFID tags on the workpiece carriers (or on the product itself) will help you by monitoring and controlling. RFID makes batch size 1 possible in mass production.

Application examples

In production processes you need to prevent defective components from being installed in a workpiece (Work in Progress – WIP). This is important due to assembly and installation errors leading to loss of time, material and sales.

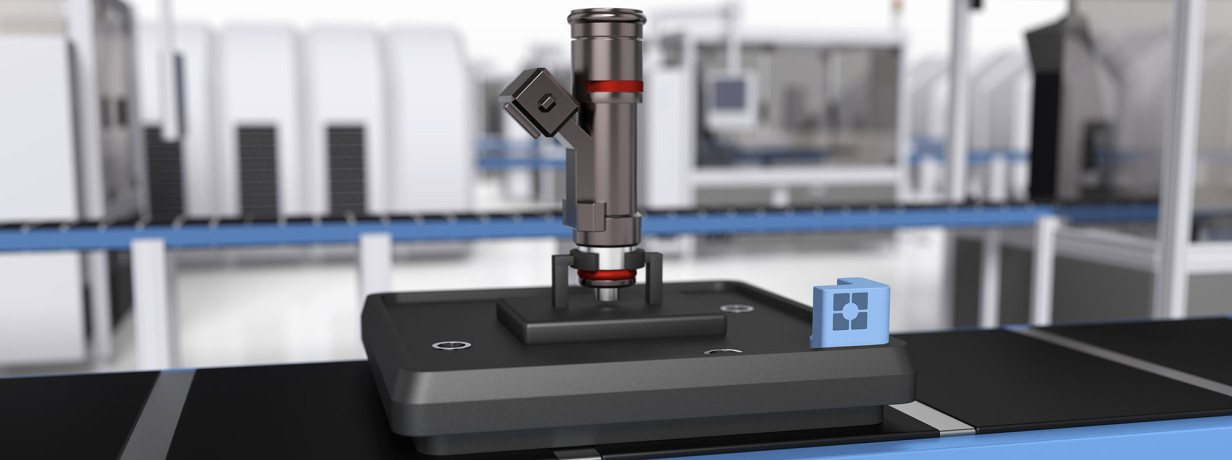

You can prevent this with RFID read/write tags on each workpiece and a read/write antenna at each workstation: The individual parts are correctly identified and the process steps permanently monitored. In addition the data carrier monitors the individual assembly steps and allows you to track the overall process.

If an error is discovered, an error code is written to the RFID tag which is then identified by the RFID read/write head at the next work step. The defective WIP can then be shunted out and reworked. This prevents a machine failure or destruction of the product.

RFID technologies

Various RFID technologies with tailored components are available for production control:

Data carriers or tags are available in various form factors, memory capacities and working distances. For example you can use data screws for their large data capacity, ease of installation and ruggedness.

Read/write heads are available even for use in tight installation conditions or for variable read distances. It's easy to connect a read/write head with integrated processor unit and bus system to the control level.

Processor units allow you to operate up to four read/write heads or antennas at different frequencies and connect to the control level through various fieldbuses.