Measurement – Linear position measurement

Positioning objects on an axis

Does your application require exact and repeated positioning of objects along a straight line? Then linear positioning systems with integrated sensors are the right choice. Their various sensor technologies let you solve special application requirements reliably – regardless of whether you are using hydraulic, electric or pneumatic modules.

Application examples

Workpieces are precisely position on the slide of a linear axis. This allows you to reduce production time to a minimum while ensuring the desired quality of workpiece machining. Magnetic encoders installed along the linear axis report the actual slide position to the controller (PLC) continuously and in real=time – even when the slide is moving at a speed of up to 10 m/s.

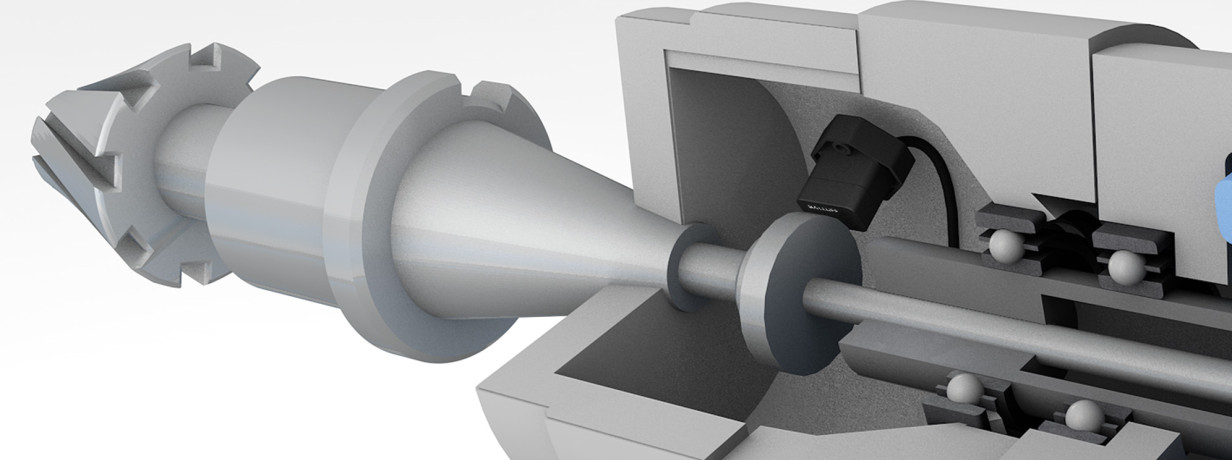

In a machine tool the clamping state of a spindle must be continuously monitored during machining. This improves results on the workpiece and increases the reliability of the overall system. Inductive positioning systems provide continuous feedback to the controller: whether the spindle is unclamped, clamped with a tool or clamped without a tool.

Sensor technologies

The following sensor technologies are ideal for linear position measurement:

Magnetic encoders can be directly integrated into linear drives. They are available in the smallest form factors.

Inductive positioning systems provide information about correct tool clamping.

Magnetostrictive linear position sensors are ideally suited for use in hydraulic drives. There they offer the same pressure rating as the hydraulic cylinder itself.