How CIP Safety Transforms Manufacturing With Network-Based Solutions

Network-based safety simplifies configurations, troubleshooting, and scalability in modern manufacturing

Reading Time: minutes

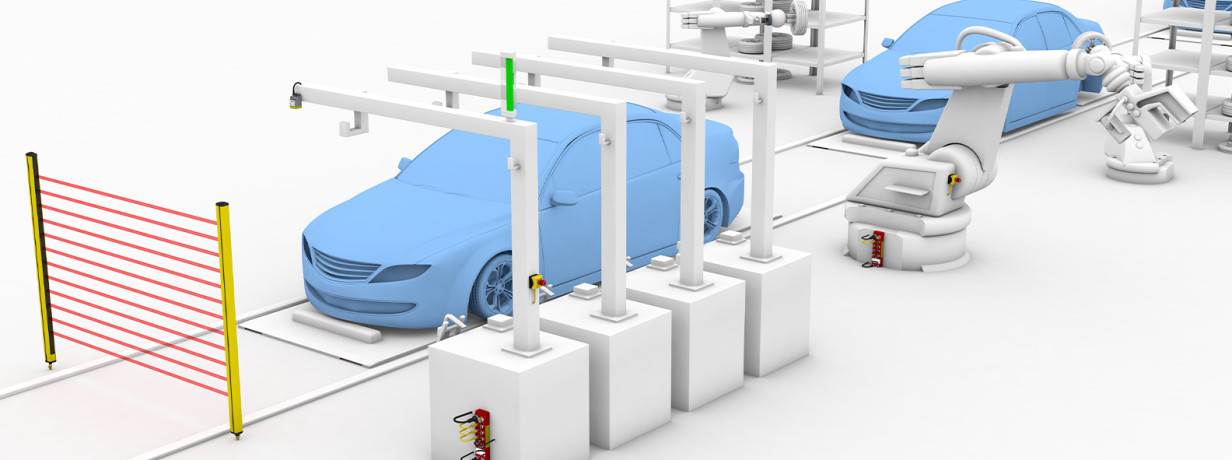

In today’s manufacturing industry, ensuring safety between machines and workers is more critical than ever. While traditional methods like hard-wiring devices were once used to promote a safer environment, technological advancements have led to new approaches. Network-based safety has emerged as a modern solution, simplifying device configuration, streamlining troubleshooting, and enhancing the scalability of machine operations.

Traditional safety methods

To understand CIP Safety, it’s helpful to first review traditional safety measures. Historically, safety methods required hardwiring devices and using safety relays to ensure safe operation. Hardwiring involved connecting vital safety components, such as emergency stop buttons, safety interlock switches, and light curtains, directly to a safety relay or controller. Although the system responded quickly to hazards, the complexity of wiring made installation and maintenance time-consuming. Troubleshooting was tedious, as each machine component had to be manually inspected to resolve issues. These challenges limited adaptability and scalability. Additionally, traditional safety relays lacked advanced diagnostics, making it harder to identify issues reliably.

Given these limitations, there’s a growing demand for sophisticated, network-based safety solutions that enhance diagnostic capabilities, scalability, and efficiency in today’s fast-paced manufacturing environments. Protocols such as IO-Link Safety, Safety over EtherCAT, PROFIsafe, and CIP Safety address these needs. This discussion focuses on CIP Safety.

CIP Safety

CIP Safety is a safety communication protocol that extends the Common Industrial Protocol (CIP). It ensures secure and reliable exchanges of safety data over the same network as standard devices. Designed to meet high compliance safety integrity levels, it operates independently of the network's physical media. Its seamless integration with existing CIP networks adds a layer of safety without compromising efficiency.

Key features of CIP Safety

Safety Integrity Level (SIL) Compliance: CIP Safety meets requirements for devices up to SIL 3, as defined by IEC 1508.

Black Channel Principle: It operates safely over standard network hardware, making it independent of physical network components and enabling faster responses for safety data and diagnostics.

Data integrity and error detection: CIP Safety includes robust mechanisms such as cyclic redundancy checks, sequence counters, and timestamping to detect and prevent data corruption.

Comprehensive diagnostics: The system provides detailed diagnostic information to identify problems quickly.

Network redundancy: It supports redundancy, allowing another system to take over in case of a failure without compromising safety.

Cross-network compatibility: CIP Safety integrates seamlessly with DeviceNet and Ethernet/IP networks.

Devices compatible with CIP Safety

Safety I/O modules: Collect data from safety sensors and activate actuators based on safety controller commands.

Safety sensors: Devices like light curtains, laser scanners, and emergency stop buttons detect and send data to the safety controller.

Actuators with safety functions: Valves, motors, or other components that include safety functions help maintain safe conditions.

Safety drives and motion controllers: These receive safety-specific commands to control motion safely according to programmable safety requirements.

Safety network devices: Gateways, switches, and other network components ensure data integrity and timely communication across the network.

Traditional methods have proven inadequate in ensuring safety between machines and workers. CIP Safety provides a modern solution, integrating advanced safety devices into industrial automation. Its network compatibility ensures seamless integration, and it enables quick and reliable communication between devices with data integrity and error detection. By extending CIP with CIP Safety, industrial automation safety takes a significant step forward.

Comment

Popular posts

Industrial sensing fundamentals – NPN vs PNP

What is a capacitive sensor?

How do I wire my 3-wire sensors?

The basic operating principle of an inductive proximity sensor

Contact form

Do you have any questions or suggestions? We are at your disposal.

Balluff Inc.

-

8125 Holton Dr.

Florence, KY 41042