Mounting technology

Versatile and flexible mounting solutions

With our assembly systems and brackets, you can adapt the sensors and equipment to your particular task.

Simple to install and adjust, these provide an exact positioning in addition to attachment –, even under difficult conditions. Balluff mounting solutions are distinguished by high-quality materials and exact specifications.

The most important benefits

- Flexible and versatile

- Compatible and universal

- Excellent price/performance ratio

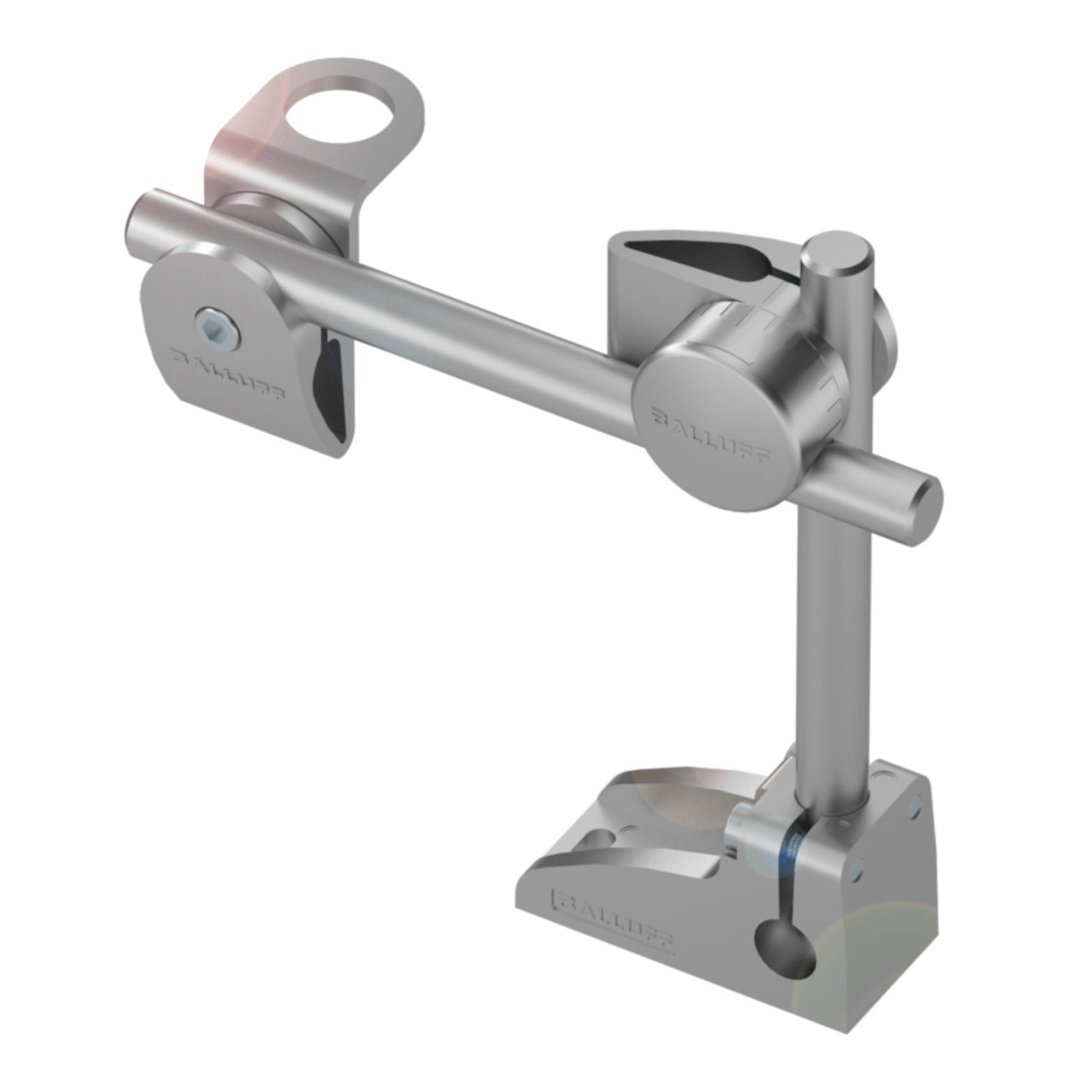

Flexible mounting system

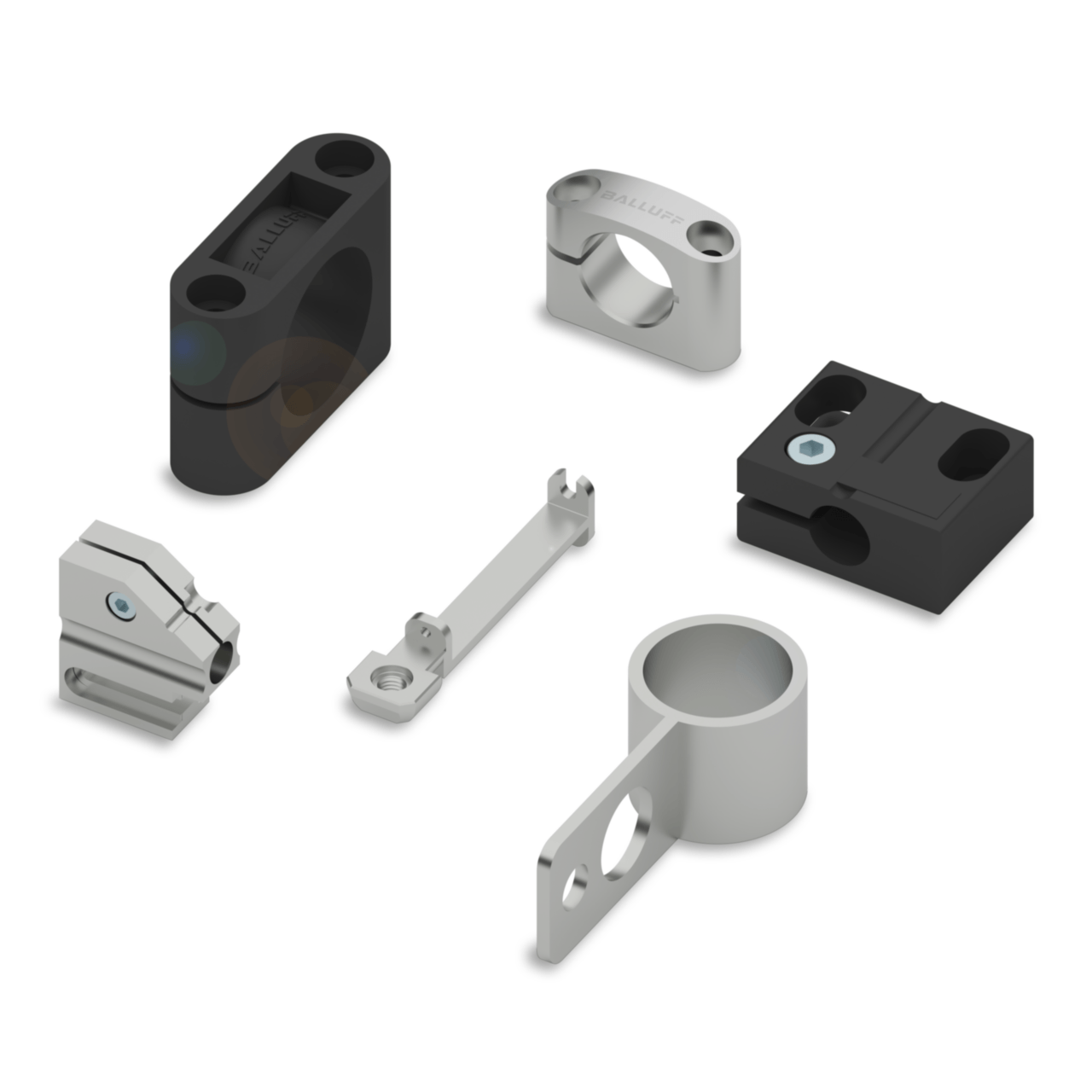

Universal brackets

Proximity sensor mounts with positive stops

Clamp without fixed stop for proximity switches