Semi-automate format changeovers with Balluff's Guided Changeover Solution

Easy semi-automated format adjustments in one system

Production comes with many challenges. One very significant and recurring problem is downtime and the related challenge of reducing it. Balluff's Guided Changeover Solution enables you to improve the Overall Equipment Effectiveness (OEE) of your production by semi-automating the changeover process of the machines, thus avoiding producing waste and reducing the duration of the format changeover.

Just three steps to an increase in plant availability and OEE

1. Identify adjustment points

2. Select and install sensors and devices

3. Create step-by-step instructions

Application areas for the Guided Changeover Solution

Our Guided Changeover Solution can be used in many industries and is particularly suited to the special requirements of the food, beverage, cosmetics, pharmaceutical, and packaging industries, especially if one of the following applies:

Small batch sizes are produced, which means machines and lines have to be adjusted frequently.

There are many changeover points requiring adjustment, which can take a long time to change.

The changeover process requires well-trained and experienced employees.

Production lines with several machines each requiring adjusting during the changeover process.

The ramp-up process after changeover requires fine tuning and takes a long time resulting in excess waste.

Reliable format changeovers of machines and lines

Balluff's Guided Changeover Solution helps you adjust length, width and height settings for guide rails, for example. Sensors provide immediate feedback on whether the dimensions are set and set up correctly.

Our RFID technologies are used to automatically detect the changeover parts and ensure that the correct format parts are being used.

To visualize the outcome, an LED stack light is attached to the machine or system, using a clearly defined color scale to allow you to read the machine status.

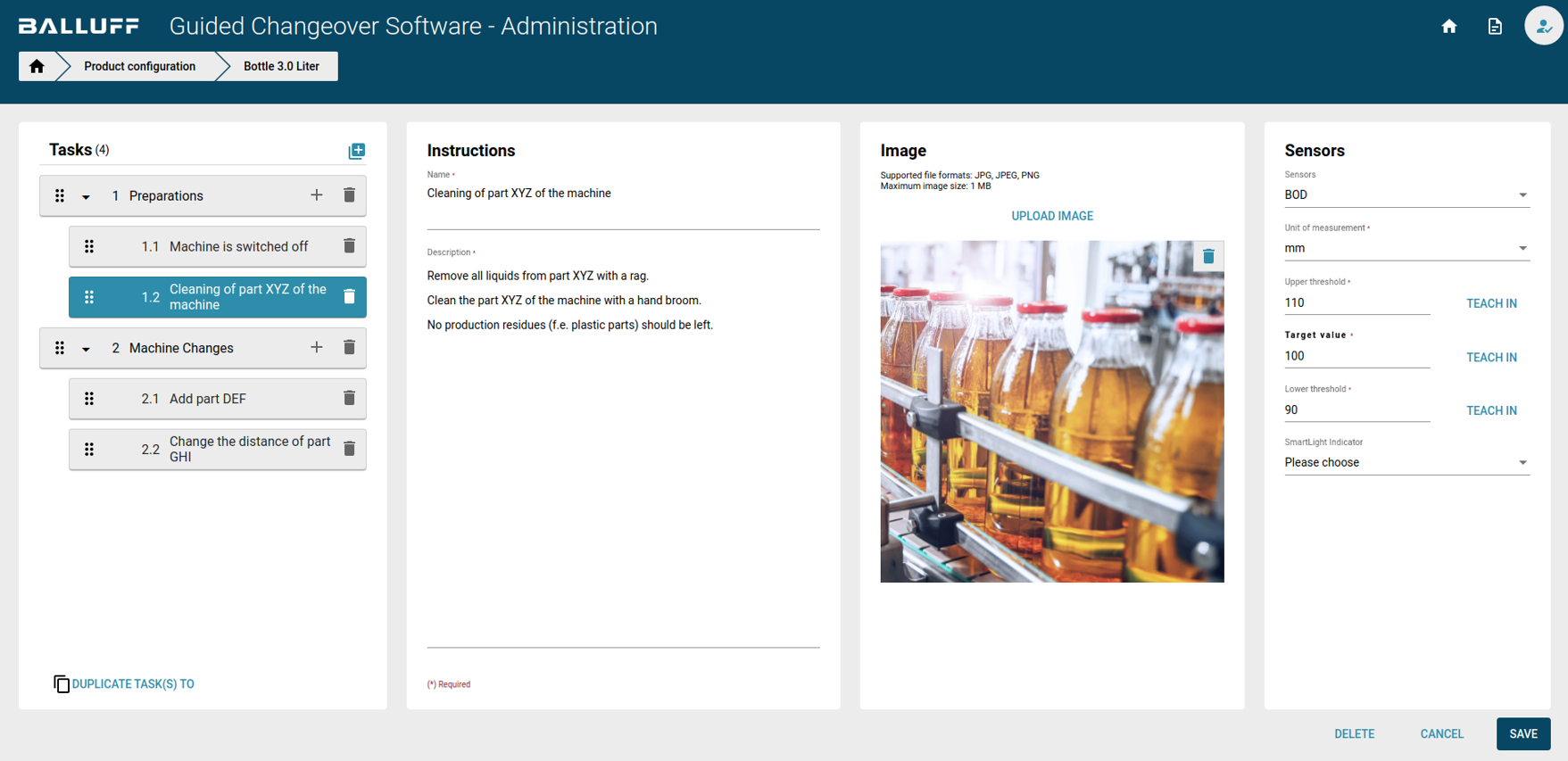

You create sets of step-by-step instructions directly in our software. All of the tasks can be described in detail and supplemented with your own pictures. Each step can be linked to a sensor for which you define the target value. Creating the steps is quick and easy--programming knowledge is not required.

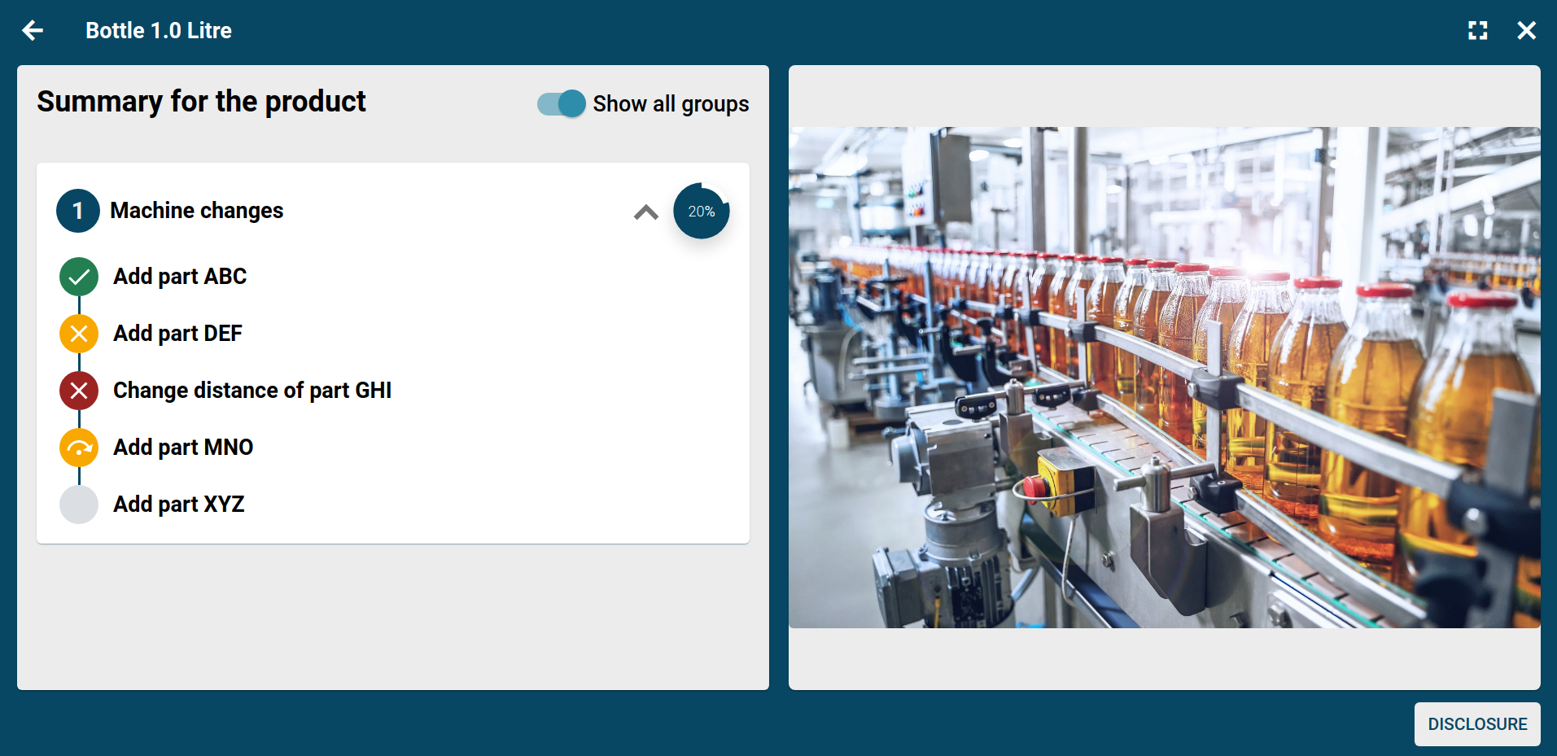

Guided Changeover Software: The heart of the solution

Simple operator guidance

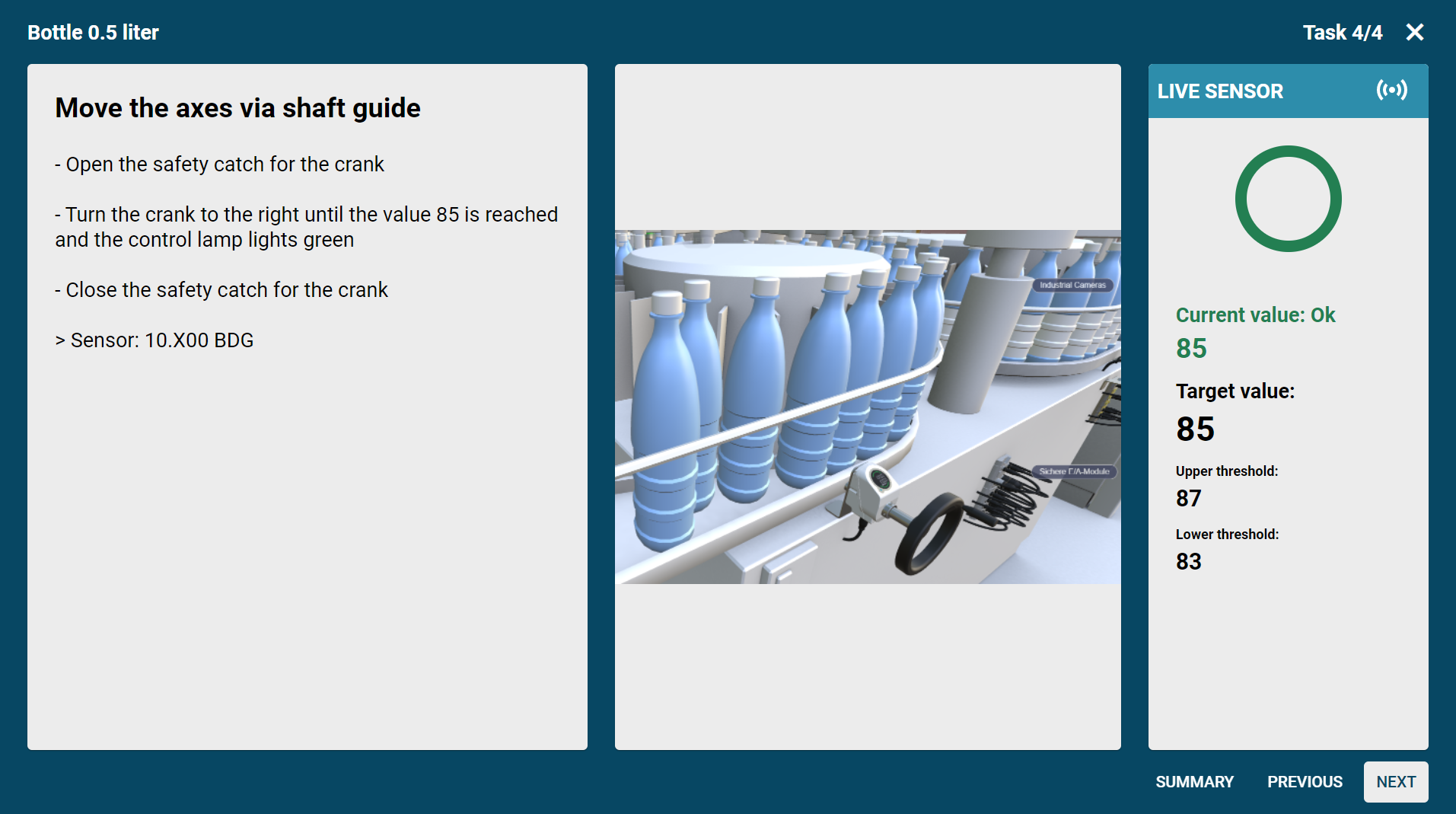

Our software guides the operator step-by-step through the changeover process, from the configuration of different formats to the start of production.

The operator guidance can be shown on various end devices, such as fixed displays or tablets. You can also choose between different languages for the user interface.

Immediate feedback

Only when the current step has been completed correctly is the next step displayed on the screen. Even inexperienced employees come up to speed quickly and adjust the change points rapidly to reduce downtime to a minimum.

There is no need for time-consuming readjustments. Manuals and high training costs will be a thing of the past.

A stand-alone retrofit solution, ready for use in the shortest possible time

You will receive our software pre-installed on an edge gateway. The system is completely independent of the company network and the machine control system, which means that you can start immediately with the format change setup.

This makes it easy to introduce our independent retrofit solution without connecting to your existing IT infrastructure.

See for yourself:

The GCS Online Demo

Would you like to test the scope of the software and find out how you can benefit from the Guided Changeover Solution? Use the free GCS online demo to navigate through the software solution and its features yourself and make your own format changes.

Simply fill out the form and get access to the online demo.

Advantages of the format changeover solution: Increase in Overall Equipment Effectiveness (OEE)

With the help of the Guided Changeover Solution's step-by-step instructions, you reduce format adjustment errors. This way, you ensure less downtime and thus higher Overall Equipment Effectiveness. Best of all, the solution can be easily retrofitted, independent of the company network or machine control system.

Guided Changeover Solutions on YouTubeLow changeover and ramp-up times

Continuous monitoring

Avoid errors and rejects

Get Started with your FREE Onsite Changeover Evaluation

Machines and lines must be adjusted very often?

Many changeover points requiring adjustment?

Well-trained and experienced employees are necessary?

Several machines in production line need adjustment?

Long time for the setup of the ramp-up process after changeover?

Get more transparency during your changeover process and operator guidance with direct feedback. With our free Audit we will show you how to increase your Changeover performance and the OEE of your machines – without any software or configuration costs.

Secure your spot for a Changeover Audit Today

What can you expect?

Benchmark the current performance & efficiency

Evaluation of the critical changepoints

Identify your scope for changeover improvement

Full Improvement report for a faster and more reliable changeover process

Demonstration of the work instruction and the direct change point feedback

Two software license variants are available: Standard and Advanced

|

Function |

Function description |

Standard software license |

Advanced software license |

|

Create instructions |

Create step-by-step instructions for necessary adjustments at each change point. |

|

|

|

Operator guidance |

During the format change, the operator is guided through each step and receives direct feedback on the setup. |

|

|

|

Monitoring |

All parameters are monitored. When a parameter is changed, an immediate alert is generated. |

|

|

|

Handshake via hardwired input |

Possibility to set up a signal for the PLC to start or stop production. |

|

|

|

Sensor technology |

License to use 8, 32, 64 or an unlimited number of sensors. |

|

|

|

Multi-user mode |

Multiple operators can perform format changes simultaneously at different points in the system. |

|

|

|

History |

Documentation of the format adjustment and the monitoring. |

|

Possible components for guided format adjustment

Customer results: Optimizing production processes through guided format adjustment

Projects that have already been implemented illustrate the potential and scale of the possible efficiency improvements: A customer already using Balluff's system solution was able to record an improvement of more than 65% in OEE in his company. Changeover time was reduced from an average of about 90 minutes to just 30 minutes, and product waste and the associated fine tuning of the machine were also significantly reduced.

1

Overview: Guided Changeover Solution

1

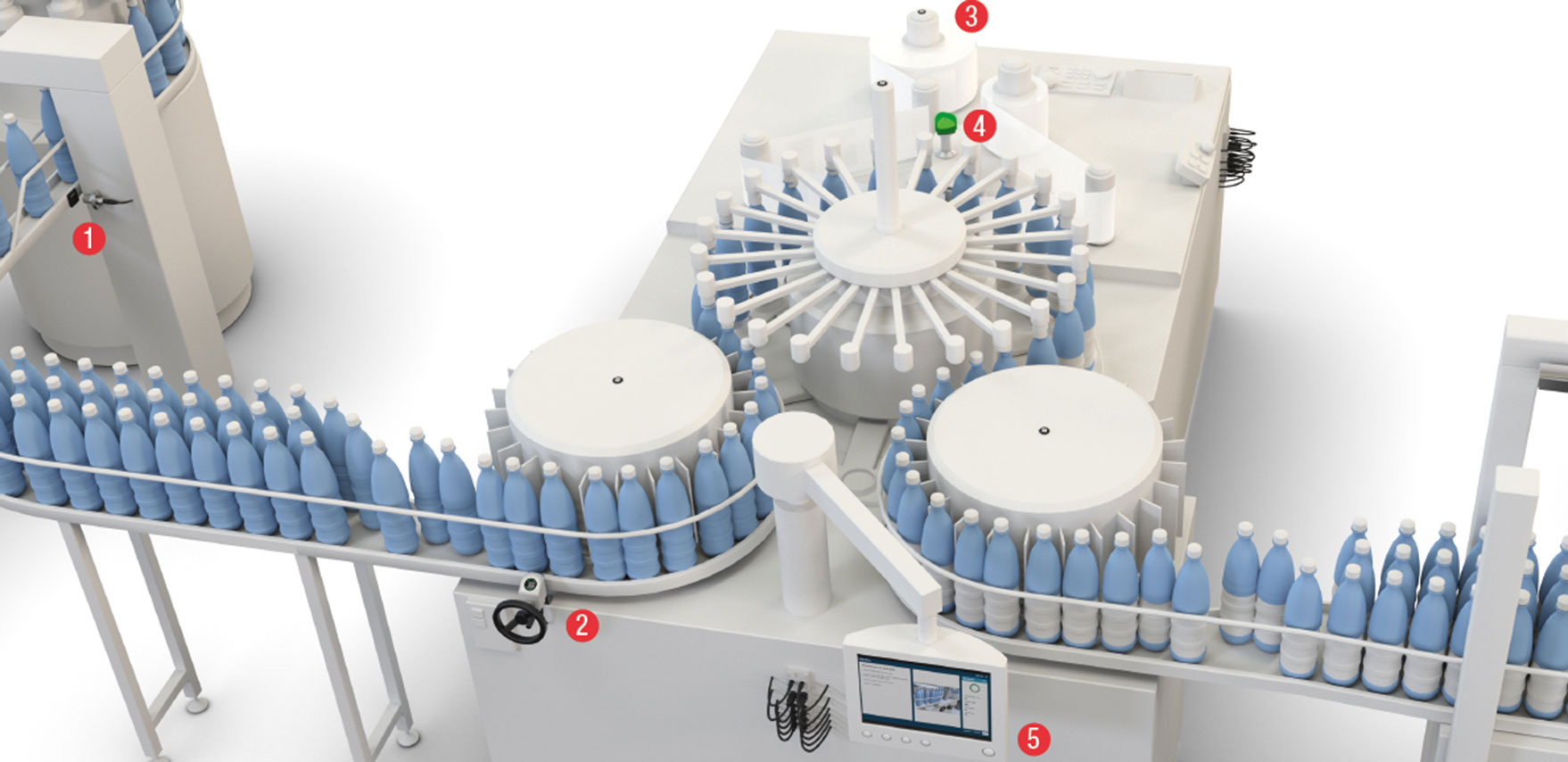

The following is an example application of the semi-automated format changeover used on a filling line.

From filling the bottles, screwing on the lids, and applying the labels, to packing them in beverage crates, find out how the Guided Changeover Solution supports format changeover at every step.

Low changeover and ramp-up times

Error prevention and minimization of waste

Easy creation and management of changeover instructions

Intuitive step-by-step operator guidance

Retrofit solution independent of company network or machine control system

2

Software: Guided Changeover Solution

2

Balluff's Guided Changeover Solution enables safe semi-automated format changeover through intuitive and simple configuration of different formats, creation and management of work steps, and detailed operator guidance.

Our software guides the operator step by step through the format changeover process when configuring different formats. This means that even employees with little experience can carry out format adjustments more quickly, and downtimes are reduced to a minimum. There is no need for time-consuming readjustment. Manuals and high training costs are a thing of the past. The instructions can be displayed both on permanently installed screens and on mobile tablets. In this way, the operator is optimally supported at every changeover point.

Every machine is different. From our broad IO-Link portfolio, we find the right sensor for the correct setting of lengths, widths and heights for every application. When changing parts, our identification systems also provide support. In this way, we cover the most diverse types of changeover processes. The sensors provide immediate feedback as to whether, for example, lengths and widths have been set correctly, and that the correct interchangeable parts have been installed.

3

Digital position adjustment

3

Our digital position indicator is suitable for setting lengths, widths and heights with a handwheel.

For each different product size, the correct distance of the guide rails for each format is stored in the Guided Changeover Solution software. The display then shows the new target sensor value in addition to the actual position. This makes it possible to set precise positions with the handwheel without error. Thanks to the real-time position feedback in the Guided Changeover Solution, the correct setting can also be seen in the software overview.

Like the master blocks, this position sensor also has IP69k class protection, making it suitable for installation in washdown environments.

Faster adjustment of lengths, widths and heights

Intuitive operator guidance with the aid of the display

Precise and error-free adjustment of dimensions

4

Length adjustment

4

As formats change, the size of objects and their packaging changes. To set the correct gripper position, our BTL length measuring system is used.

The accepted threshold values as well as the target and actual values are displayed in the software. This makes it easier for the operator to make the correct setting.

Facilitates the setting of correct length dimensions

Software enables verification of correct settings

5

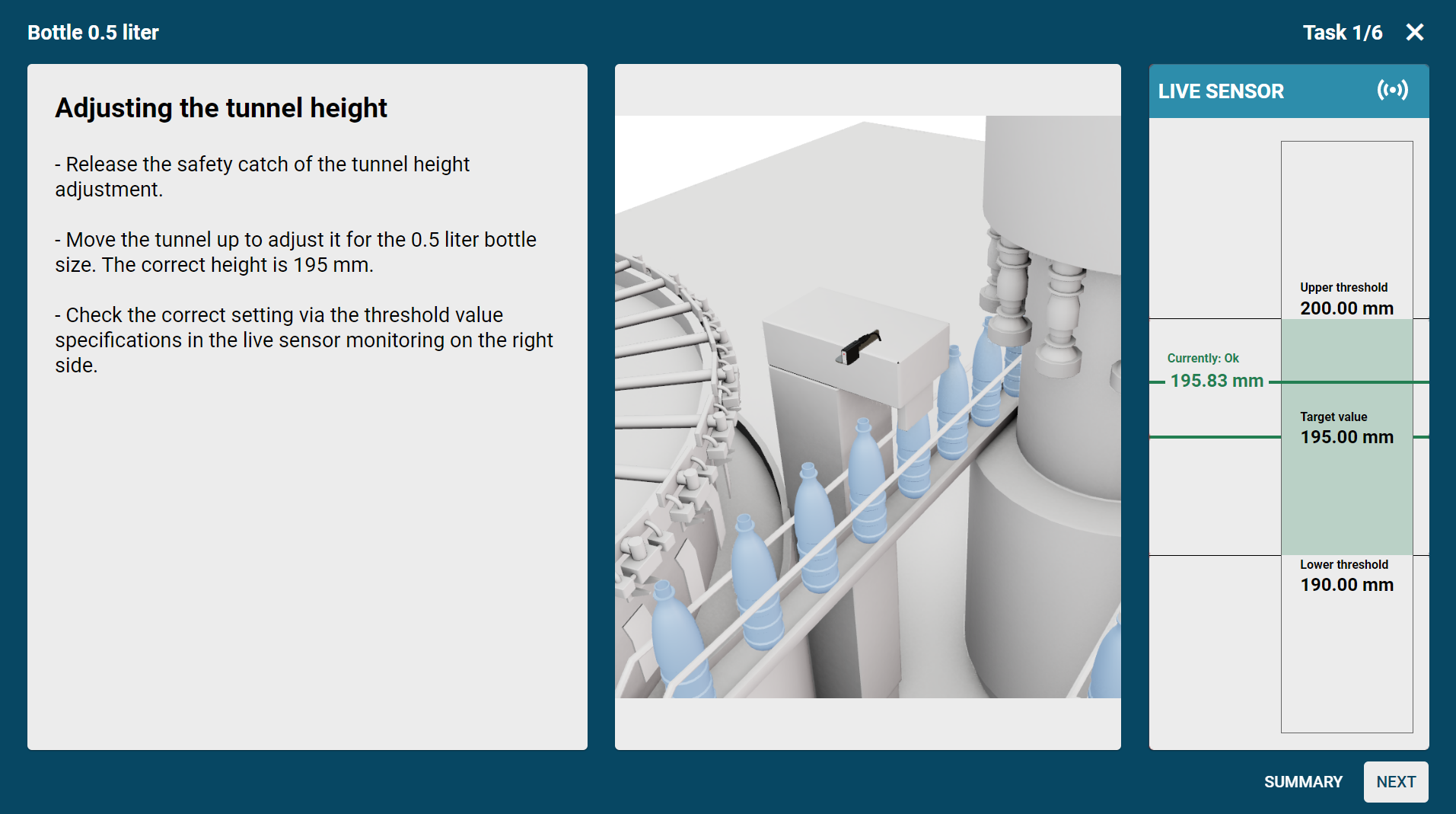

Height adjustment

5

Reliably position objects, regardless of their surface material. Optical distance sensors can be used to set distances in format adjustment. In this example, different format sizes require height adjustment of the tunnel.

A display of threshold values and the optimum distance set in the software provides the operator with guidance and real-time feedback on the current settings of the optical sensors and the tunnel height.

Facilitates setting the correct height

Software allows verification of correct settings

6

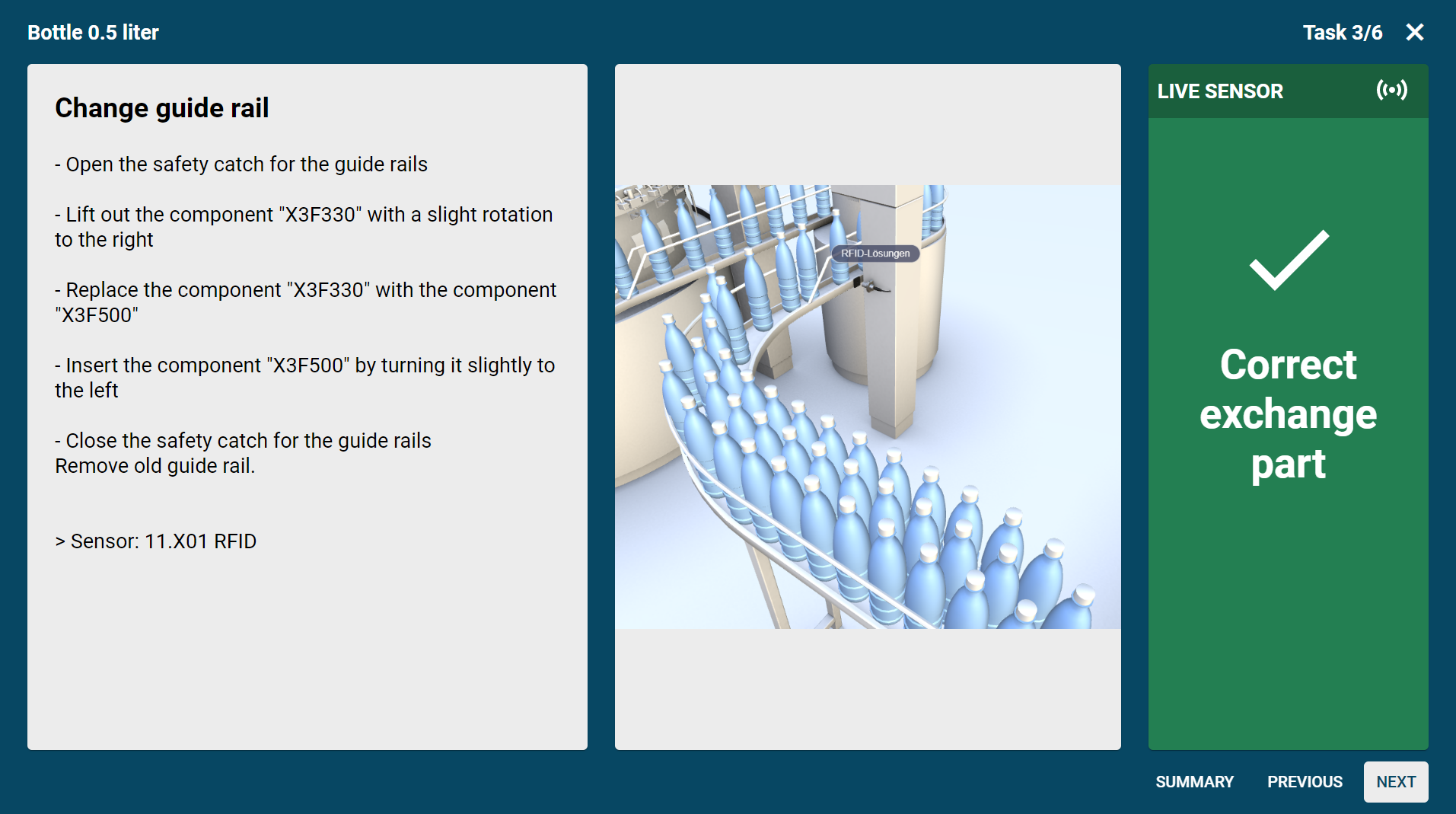

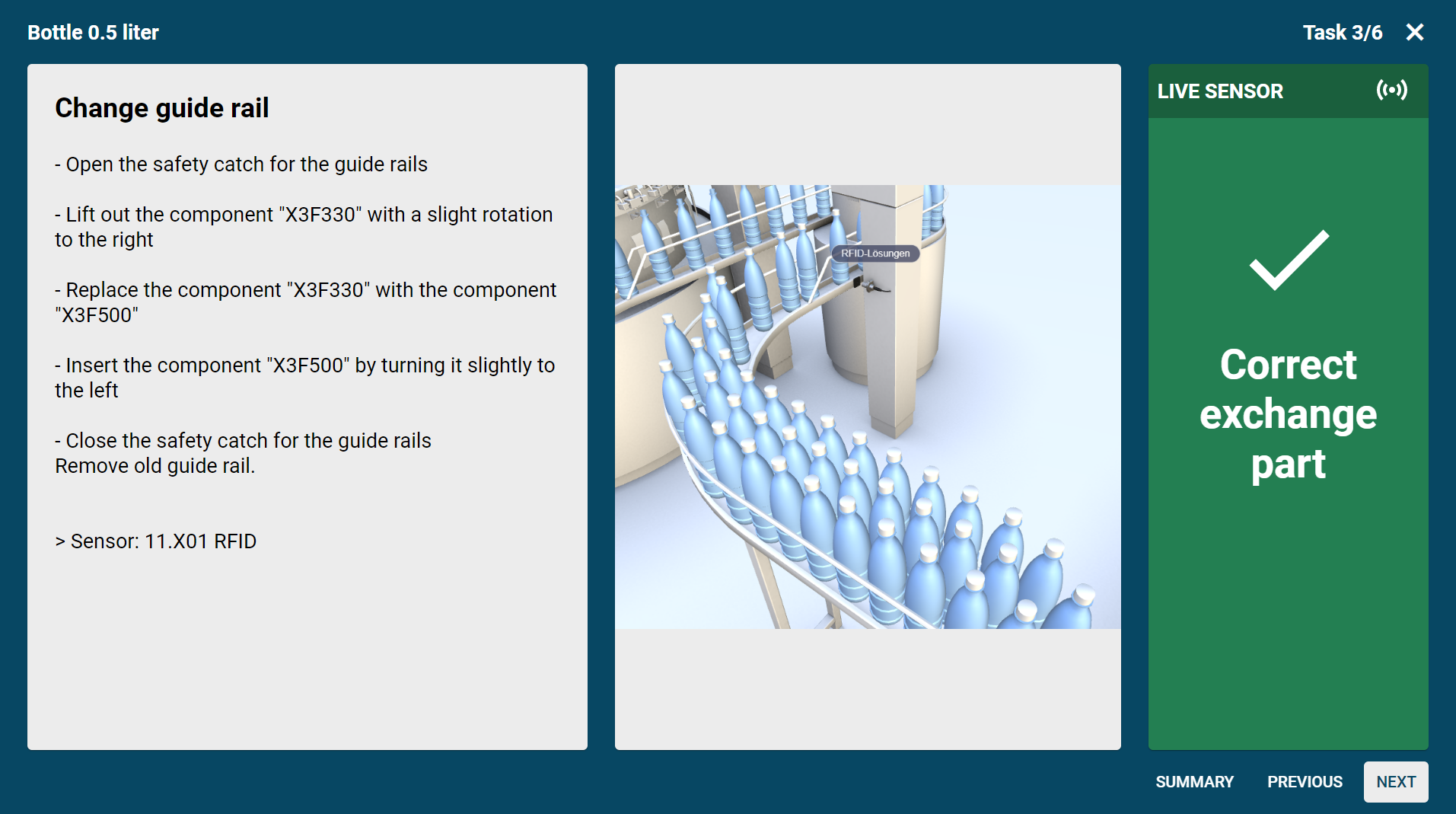

Unique format part detection

6

Automatic detection of interchangeable parts ensures that the correct format part is inserted during changeover. This is achieved with our identification technologies. At all changeover points, RFID read/write heads check the exchangeable parts, which are equipped with RFID data carriers.

Depending on requirements, the change part can be identified once by the RFID read/write head or monitored continuously.

This example shows a one-time identification of the exchangeable part. The data carrier is located on a label roll, e.g. for the 1-liter bottle size. When the format is changed, the new label roll is identified once with an RFID read/write head before insertion.

Ensures that the correct format part has been inserted

Detection of different change parts at one point

7

Continual change part detection

7

To permanently ensure that the correct exchangeable part is present, the exchangeable part can be monitored at the exchange point using an RFID read/write head.

This example shows permanent monitoring of the guide rail for a specific bottle size.

Ensures that the correct format part has been inserted

Permanent monitoring of the format parts

8

Status display

8

With our SmartLight, you know what the status of the format parts is at all times. It reliably monitors the status of the system and visualizes the progress of the format change to guide the operator through the process.

During production, the correct positions and settings of the format parts are monitored.

Real-time feedback of format part settings

Faster error detection and correction

9

Status display at the setup point

9

With the SmartLight Indicator, the correct setting at individual setup points on the machine can be verified.

By changing the color of the SmartLight, the use of the correct exchange part or the setting of the appropriate length is visualized directly at the changeover point. This saves walking back and forth to check the settings on the HMI.

Real-time feedback on the status of the format part setting.

Provides direct feedback when the setup point is set correctly

10

Network block

10

Our central network block collects data from all of the connected sensors and communicates with the Guided Changeover software. In addition, all settings and parameterizations of the sensors are made via the network block.

With different housing designs, the master block can be matched to the environmental conditions. Especially for the food and beverage industry we offer blocks with a protection class up to IP69k which are suitable for mounting in washdown environments.

Fast integration and easy configuration

Consistent diagnostics

IP69k protection class for washdown environments

Powerful end-to-end network

Would you like to know how you can benefit from the advantages of the Balluff Guided Changeover Solution in your company and optimize the overall productivity of your machines and systems? We would be happy to advise you on this. Simply contact us here.

Downloads

-

Case Study: Guided Changeover Solution reduced can labeler changeover downtime by 50 % (EN)

-

Guided Changeover Solution – system simplifies semi-automated format adjustment